High - Performance Material Advantages

Utilizes 100% HDPE and PP, ensuring superior hardness, reducing costs significantly, and setting new benchmarks in the industry.

Utilizes 100% HDPE and PP, ensuring superior hardness, reducing costs significantly, and setting new benchmarks in the industry.

Enables use of 100% PLA for environmentally friendly bubble films and 100% recycled materials, promoting sustainable manufacturing practices.

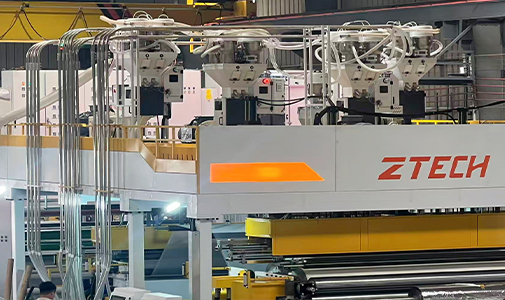

The Spanish customer needs a 3-meter-wide non-woven fabric laminating machine for waterproof applications, thus having high requirements for product quality. It is required to be suitable for laminating various materials such as EVA, PP, HDPE, and LDPE on non-woven fabrics, and also needs to test the thickness uniformity of the 3-meter width.

They adopted our non-woven fabric laminating machine featuring a large unwinder (max. Ф1200mm), high capacity (600-900 kg/h production), wide format (3000 mm max working width), multi-material compatibility (PP/LDPE/HDPE), precision coating via T-die for uniform lamination, smart OC-X-ray thickness monitoring, and a climate-controlled air-cooled electrical cabinet.

The machine meets the high-quality requirements for waterproof non-woven fabric lamination with multiple materials, ensures the thickness uniformity of the 3-meter width through precise coating and smart monitoring, and has high production capacity, fully satisfying the customer's needs.

To cut material costs, the Italian customer intends to eliminate the third layer formed by the auxiliary extruder's screw on their air bubble film machine. They require the air bubble film machine to directly laminate HDPE or EPE foam materials onto the 2-layer bubble film, with the lamination speed of the air bubble film machine not lower than 50 meters per minute.

We optimized the air bubble film machine by abandoning the auxiliary extruder configuration and adopting a dual Teflon heating roller system for preheating. The Teflon-coated heating rollers on the air bubble film machine uniformly preheat the surface of the 2-layer bubble film and the composite materials (HDPE/EPE foam) to the optimal bonding temperature. This upgraded design of the air bubble film machine enables direct and stable lamination without the need for an additional PE film as an adhesive layer, while ensuring the lamination speed of the air bubble film machine reaches and exceeds 50 meters per minute.

The dual Teflon heating roller preheating solution for the air bubble film machine eliminates the need for the auxiliary extruder and the additional PE film, directly reducing raw material costs for the air bubble film machine operation. The lamination speed of the air bubble film machine stably maintains above 50 meters per minute, doubling the efficiency compared to traditional air bubble film machine processes. Additionally, the Teflon coating on the air bubble film machine’s heating rollers prevents material adhesion, reducing manual cleaning workload for the air bubble film machine and achieving comprehensive improvements in cost control, production efficiency, and operational convenience of the air bubble film machine.

The Hungarian customer needs a 2.5-meter-wide bubble film production line. With the EU's increasingly strict requirements on recycled materials, the recycled material content in bubble film must not be less than 30%, otherwise it cannot be sold. However, the use of recycled materials tends to reduce the quality of bubble film.

We adopted the ABA co-extrusion technology for the 2.5-meter-wide bubble film production line. This technology divides the bubble film structure into three functional layers: the A layers (outer layers) use virgin materials to maintain the film's surface smoothness and tactile quality, while the B layer (core layer) is dedicated to incorporating recycled materials. By optimizing the material ratio and extrusion parameters, we ensured the recycled material content meets the EU's 30% minimum requirement, and even allows for higher proportions of recycled materials to be used without affecting the bubble film's overall quality

The ABA co-extrusion solution fully complies with the EU's recycled material content regulations, enabling the customer's products to be legally sold in the European market. While using a large amount of recycled materials to reduce raw material costs, the bubble film maintains excellent surface quality and structural stability, achieving a balance between environmental compliance, cost control and product quality.

The Korean bubble film producer faces challenges in paper tube cutting—their 2.5m-wide bubble film machine switches production between 2m, 1m, and 0.5m film widths, requiring matching paper tubes of different lengths, while manual cutting is inefficient and inconsistent. They need a professional solution to resolve this cutting bottleneck.

We developed an in-line automatic paper tube cutting device tailored to their 2.5m-wide bubble film machine. It supports length adjustment for 2m, 1m, and 0.5m paper tubes (matching the machine’s film width switches) and integrates with the bubble film production line, realizing synchronous in-line cutting without disrupting the production flow.

The in-line device solves the customer’s paper tube cutting,ensuring consistent length accuracy for different tube specs. It eliminates manual handling, boosts line efficiency by 40%, and seamlessly adapts to the 2.5m machine’s width switches, fully meeting their flexible bubble film production needs.

Czech customer needs a high-output bubble film machine, with a thickness of 500 kg per hour, a production capacity of at least 600 kg per hour, and a speed of 70-80 meters per minute.

We enlarged the screw and added fans to cool each temperature zone of the screw to achieve high output. Besides, the diameter of the bubble roller was increased to enhance the cooling effect.

Meets the customer's requirements for high output, speed and thickness, ensures stable production, and improves production efficiency.

The UK customer requires a high-speed large bubble film machine with a speed of over 70 meters per minute. However, due to limited factory space, a compact high-speed bubble film machine is necessary. Additionally, it demands a bidirectional winding function, enabling the bubble film to be wound internally at times and externally at other times.

To tackle the space constraint, we implemented a horizontal platform-type structure, which optimizes spatial utilization. Concurrently, we developed a bidirectional winding mechanism to fulfill the customer's requirement of both internal and external winding, while ensuring the machine operates at over 70 meters per minute.

The compact structure fits the limited factory space, the bidirectional winding function enhances operational flexibility, and the speed of over 70 meters per minute ensures high production efficiency, fully meeting the customer's production needs.

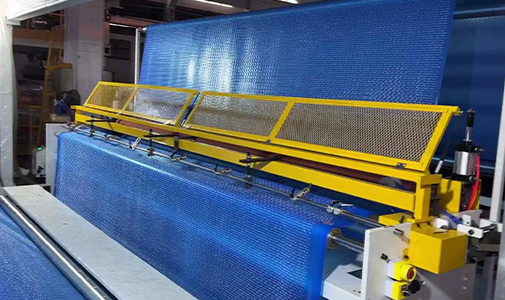

The Brazilian customer demands blue bubble film pool film with a width of 4.2 meters, a dimension that represents an unprecedented super-wide specification in the bubble film manufacturing industry, posing significant technical challenges in terms of material uniformity and structural stability.

To address the critical issue of width-induced material inconsistency, we employed a precision-machined die head with micron-level tolerance control, ensuring homogeneous melt distribution across the entire 4.2-meter span. Concurrently, a reverse winding mechanism was integrated into the production line, enabling external bubble orientation during the winding process to facilitate direct market distribution without additional processing.

The implementation of advanced die head technology successfully achieved 4.2-meter super-wide blue bubble film pool cloth with exceptional dimensional stability and material uniformity. The reverse winding configuration optimizes post-production logistics, allowing for immediate commercialization, thus fully satisfying the customer's specialized requirements in both product performance and operational efficiency.

French customer needs bubble film in 3m, 5m, 10m, 20m, 25m coreless small rolls, with shrink film and labeling.

They bought our ZT160-APC automatic coreless rewinder (part of integrated line):

CORELESS REWINDING: 3-30M lengths (max. 600mm), tape-compatible, no paper cores.

AUTO-LABELING: High-speed A4 applicator with hot-melt adhesive.

SMART SHRINK TUNNEL: Precise temp control, adjustable airflow for bubble-free sealing.

Solves manual rewinding/packaging. Saves cost/space, boosts profits via efficient functions.

The Italian customer requires 3 sets of embossing rollers mounted on the machine to enable rapid and flexible switching between different molds. Moreover, they demand direct lamination of EPE materials via hot rollers without relying on an auxiliary extruder, with the goal of saving one layer of PE material.

We integrated 3 sets of high-precision embossing rollers into the machine, equipped with a quick-change mechanism that allows mold switching within10 minutes, ensuring efficient transition between different production specifications. Simultaneously, we developed a hot-roll lamination system with precise temperature control (±1℃) and pressure regulation, which replaces the auxiliary extruder. This system directly bonds EPE materials through thermal activation, eliminating the need for an additional PE layer as an adhesive medium.

The 3 sets of embossing rollers with quick-change functionality meet the customer's demand for flexible production switching. The hot-roll lamination technology without an auxiliary extruder not only saves PE material costs but also reduces production processes, enhancing overall production efficiency while ensuring stable lamination quality of EPE materials.

The American customer intends to utilize ABA co-extrusion distribution technology to produce 6-layer composite bubble film. The key requirements are to enhance the hardness and hand feel of the bubble film, enabling it to be applicable for manufacturing bubble film envelopes. This puts forward specific demands on the structural stability and material performance of the bubble film.

We employed the ABA co-extrusion distribution technology for the production of 6-layer composite bubble film. This technology enables rational distribution of materials in each layer, with the outer layers adopting materials with higher hardness to enhance the overall rigidity of the bubble film, and the inner layers selecting materials with better toughness to improve the hand feel. Through precise control of the extrusion process, the layers are tightly combined, ensuring the stability of the 6-layer structure. The resulting bubble film meets the performance requirements for making bubble film envelopes.

The 6-layer composite bubble film produced by ABA co-extrusion distribution technology has significantly improved hardness and hand feel compared to traditional bubble films. It can well meet the production needs of bubble film envelopes, providing customers with high-quality packaging materials and helping them expand their market share in the packaging field.

Indian customer needs bubble film made from 100% PP and recycled materials, and requires it to be made into bubble film sheets.

We improved the screw design to enable the use of 100% PP, and adopted high-low T-die to ensure cooling. The solution includes:

Meets the customer's material and sheet requirements, ensures product quality and stability, and expands application scenarios.

The Turkish customer requires producing 7-layer bubble film at one time with a 2.5-meter-wide machine.

We adopted advanced technologies to ensure the customer can perfectly produce 7-layer bubble film. These technologies involve precise control of the extrusion process, optimized material distribution among layers, and a stable width control system for the 2.5-meter dimension, which together guarantee the uniformity and structural stability of the 7-layer bubble film.

Successfully met the customer's requirement of producing 7-layer bubble film with a 2.5-meter width in one go. The produced bubble film has excellent layer adhesion and consistent width, providing a reliable solution for the customer's production needs.

Due to the high labor costs in South America, the Argentine customer requires an automated system for precise calculation of bubble film thickness. They need the machine to automatically and accurately produce bubble film with the set thickness, such as 28 grams per square meter, while expecting to reduce production and labor costs through efficient material management.

We integrated an Italian weighing system into the production line to achieve precise automated control of bubble film thickness. This system enables the machine to automatically adjust production parameters based on the set weight per square meter (e.g., 28g/m²), ensuring the output thickness matches the preset value with high accuracy. Additionally, the system is equipped with a four-color mixing function, which supports flexible switching between different production formulas. By automating the material proportioning and thickness control processes, it minimizes manual intervention.

The Italian weighing system realizes precise automated control of bubble film thickness, eliminating manual calculation errors and ensuring stable product consistency. The four-color mixing function adapts to diverse production formulas, reducing material waste and lowering labor costs significantly. Overall, it enhances production efficiency while cutting down comprehensive costs, perfectly addressing the customer's needs in the context of high labor expenses in South America.

The Indian customer intends to utilize 100% recycled PP material of inferior quality, characterized by a gray hue, to minimize raw material costs. Additionally, the requirement includes processing the output into bubble film sheets with a fixed length of 2 meters.

We implemented targeted process optimization to accommodate the 100% recycled PP material, addressing issues such as material impurity and melt instability through modified screw design and enhanced filtration systems, ensuring consistent production of gray bubble film despite the low-grade feedstock. Concurrently, a high-precision servo-driven cutting mechanism was integrated into the production line, enabling accurate slitting of the bubble film into 2-meter sheets with a dimensional tolerance of ±5mm.

The optimized process successfully enables the utilization of 100% recycled PP material, achieving a 30% reduction in raw material expenses for the customer. The precision cutting system ensures strict compliance with the 2-meter length specification, while the stable production of gray bubble film sheets meets the customer's cost-saving objectives without compromising on basic product performance, thereby enhancing overall production economy.