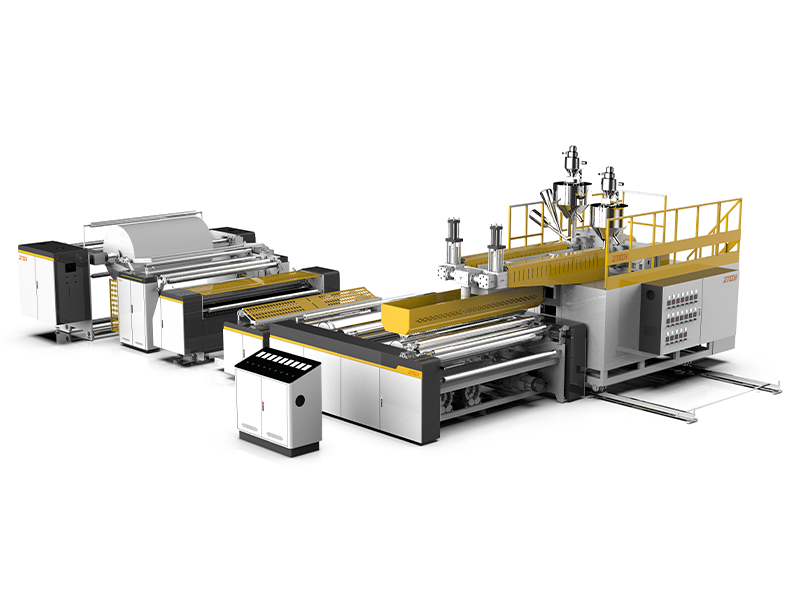

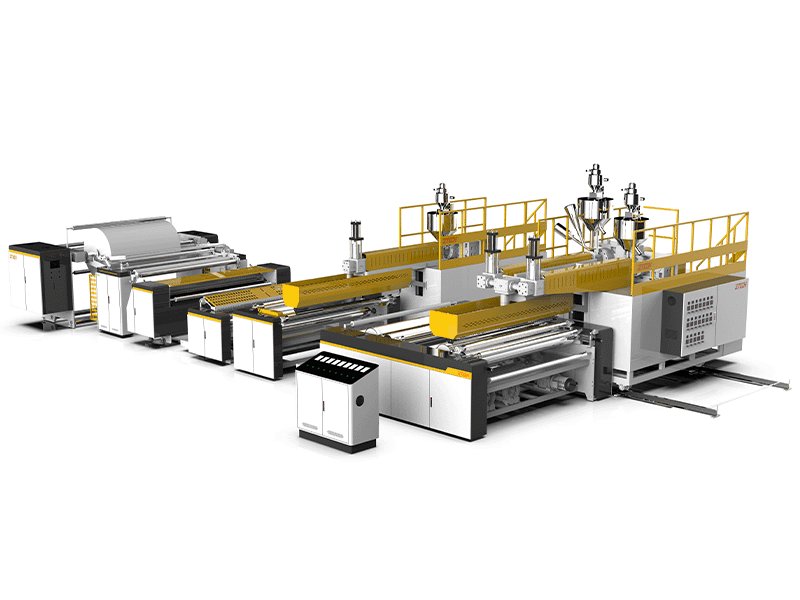

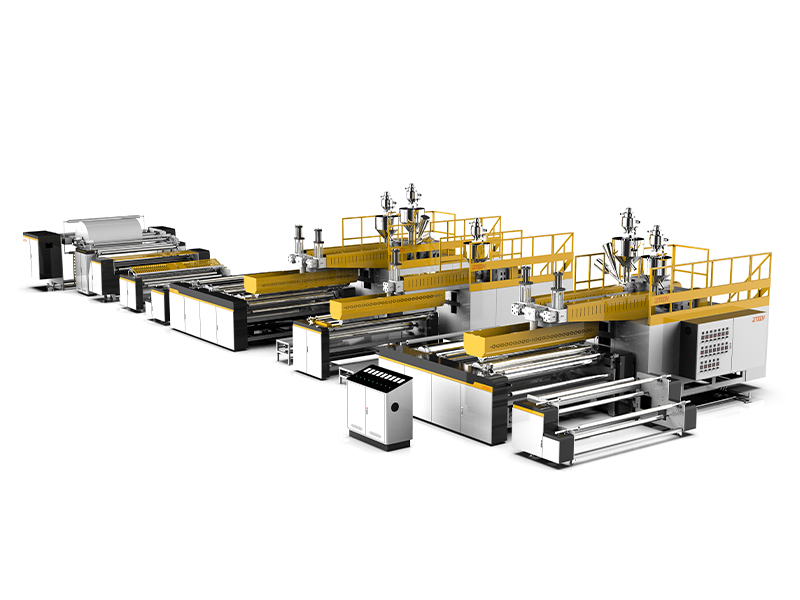

ZTECH provides a range of efficient bubble film machines, specially designed for high-efficiency production of protective packaging. This series of machines can support the production of various bubble film specifications, ranging from the basic double-layer film to the advanced multi-layer co-extrusion structure.

• 2-Layer Air Bubble Film Machine—Efficient production of standard bubble film with separate bubble and PE base layers.

• 3-Layer Air Bubble Film Machine—Flexible extrusion for classic 3-layer configurations or simplified 2-layer output for different end-use applications.

• 5-Layer Air Bubble Film Machine—Advanced multi-layer line that can produce lamination films with PE-coated materials like aluminum foil, Kraft paper, and EPE foam.

• 7-Layer Air Bubble Film Machine—High-performance extrusion capable of even broader lamination combinations for applications requiring enhanced strength, insulation, or cushioning.

• ABA Coextrusion Air Bubble Film Machine—Utilizes a unique 3-in-1 co-extrusion structure for bubble and base layers, ideal for products such as aluminum film express bags with superior toughness and air retention.

• Nylon Coextrusion Air Bubble Film Machine—Features a high-performance 5-in-1 coextrusion design optimized for long bubble air retention and high-end packaging applications, especially for goods requiring extended protection during long-distance transport.