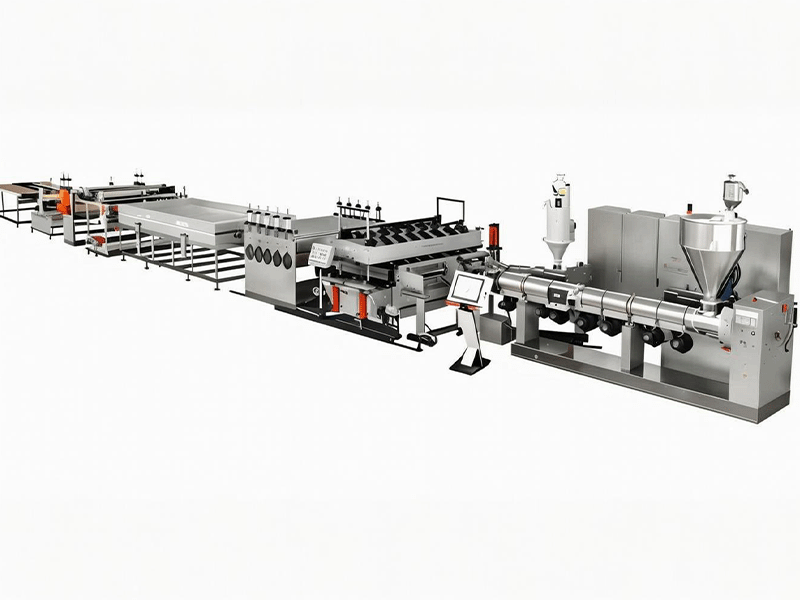

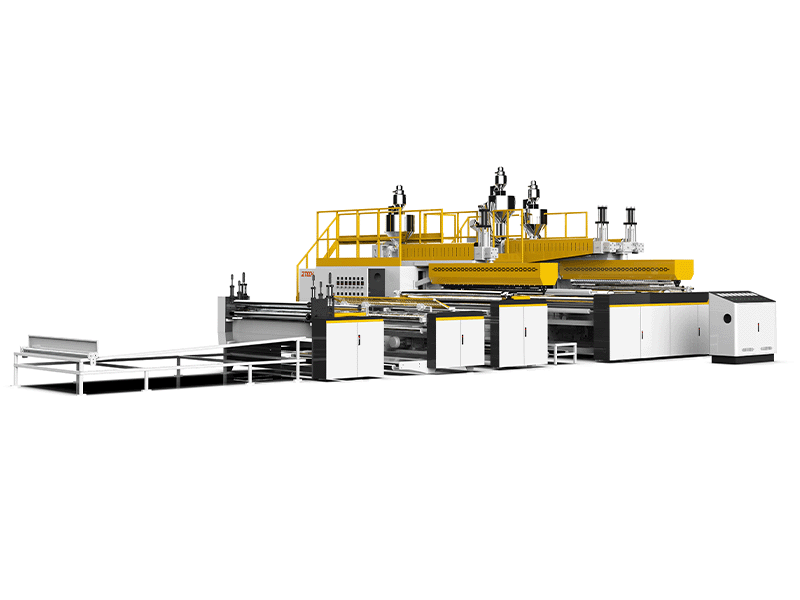

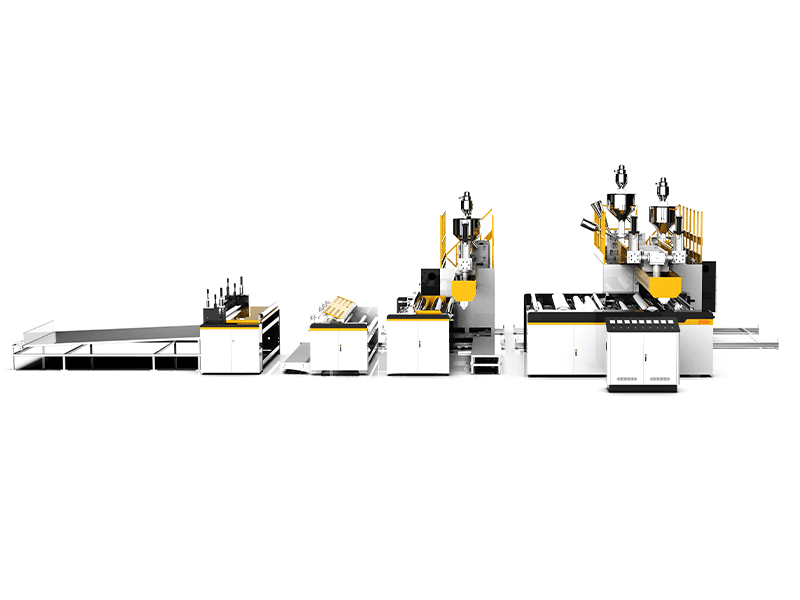

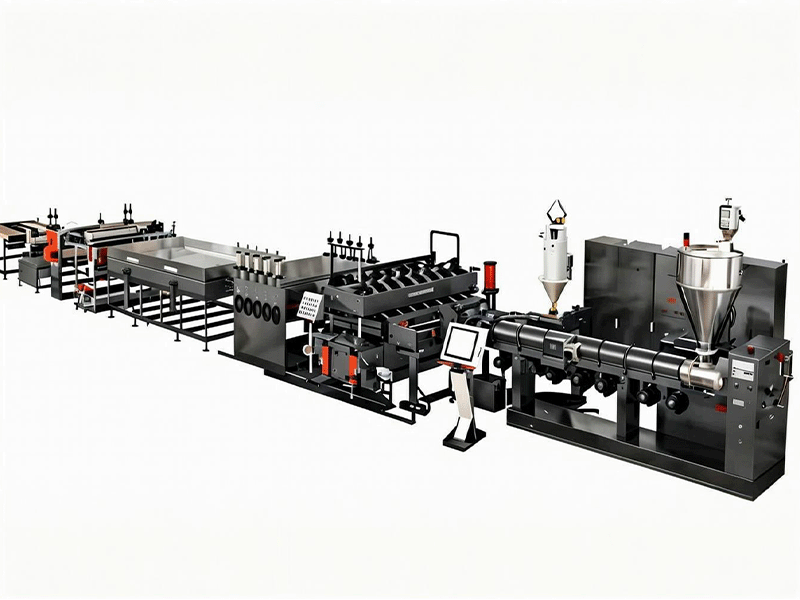

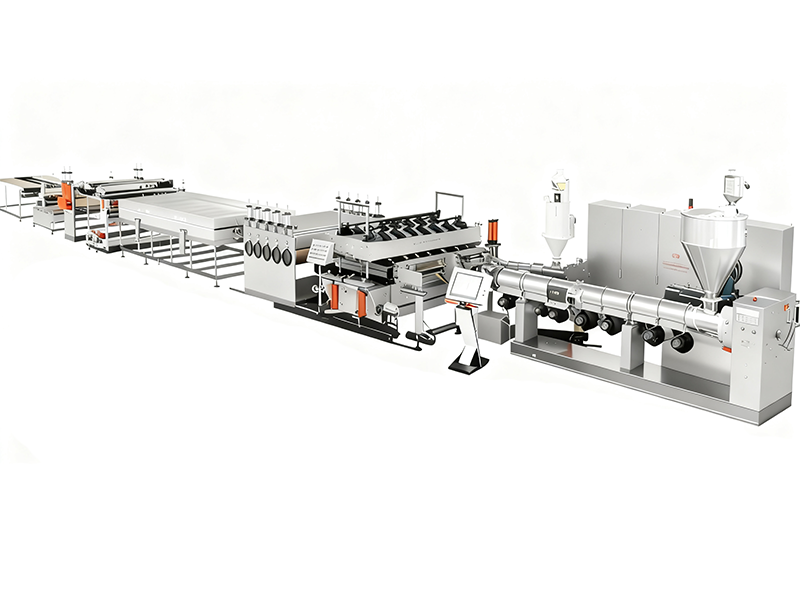

PP Bubble Board Machine

This multi-functional equipment works as a PP bubble sheet machine, PP bubble guard machine, and PP bubble board machine—specializing in producing 3-layer PP material bubble sheets/boards. It integrates extrusion, forming, drying and slicing to create rigid, waterproof PP bubble products.