Description

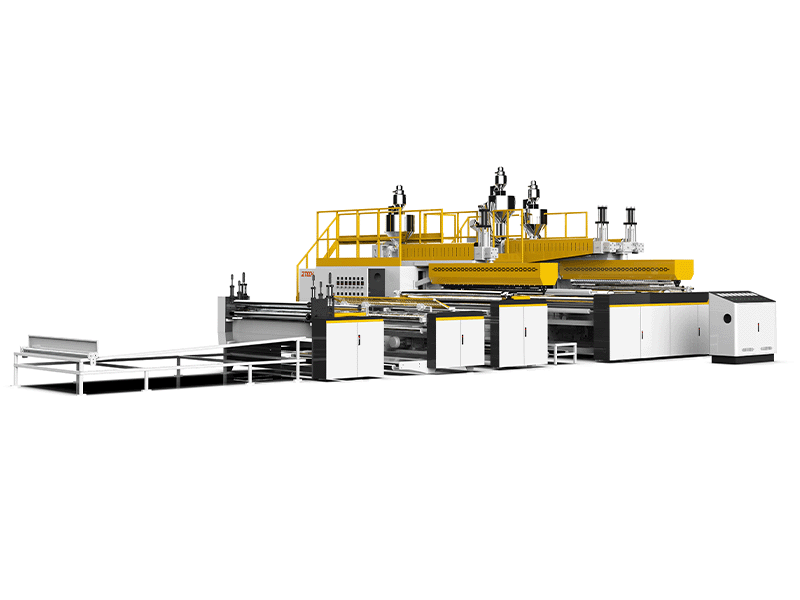

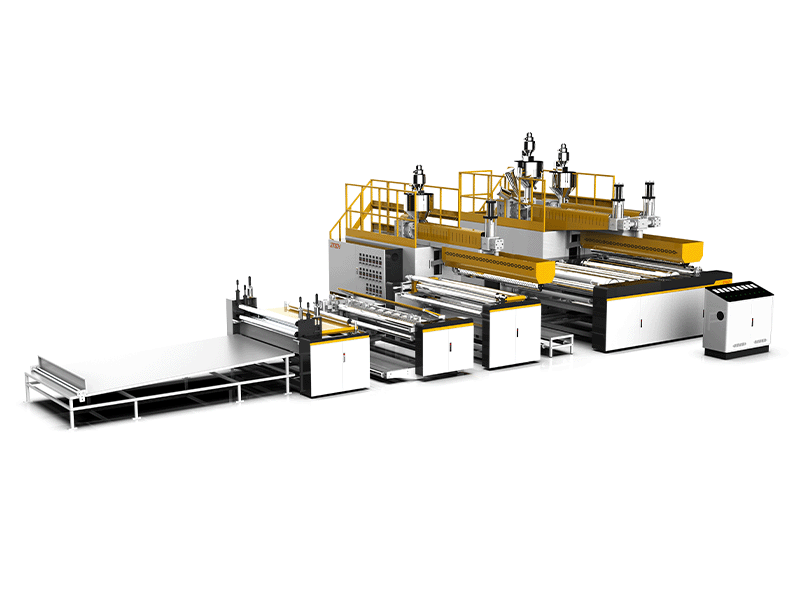

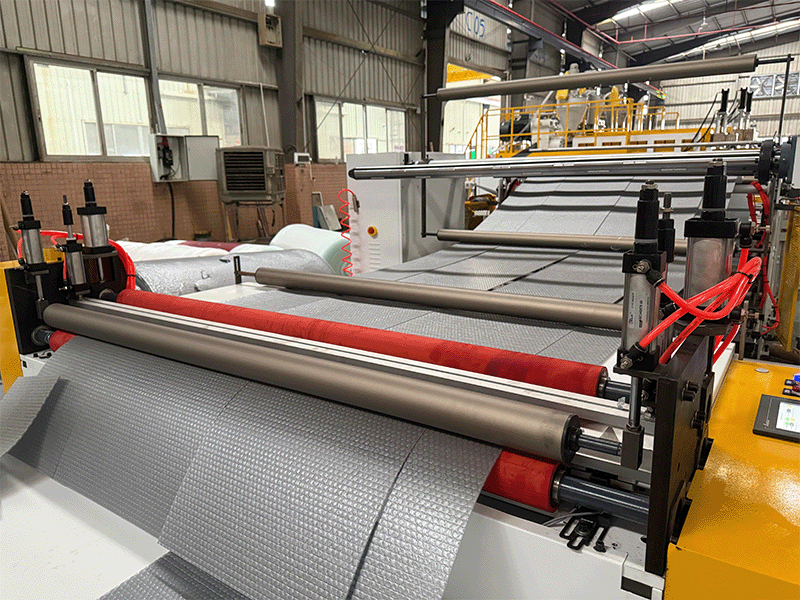

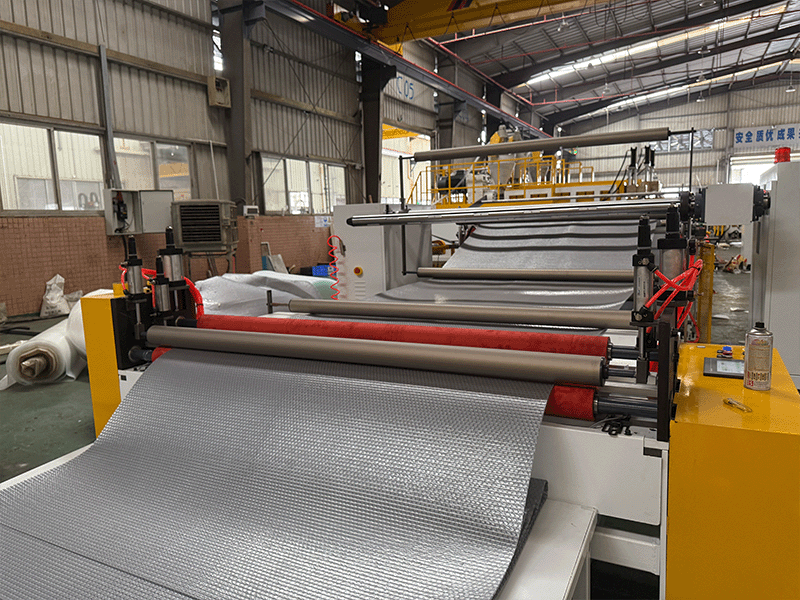

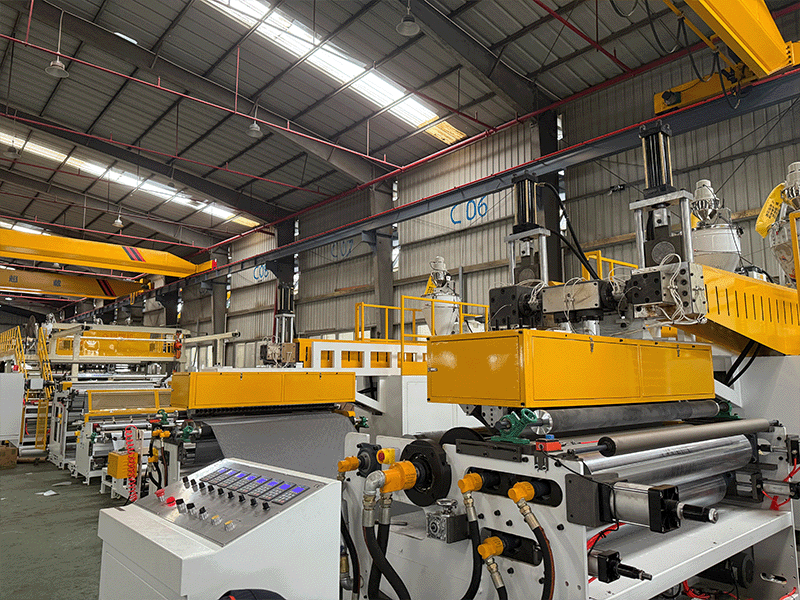

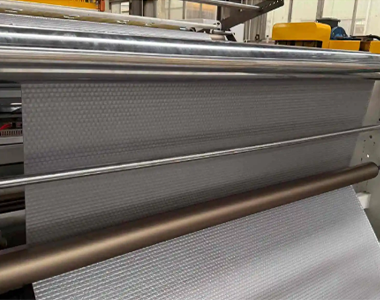

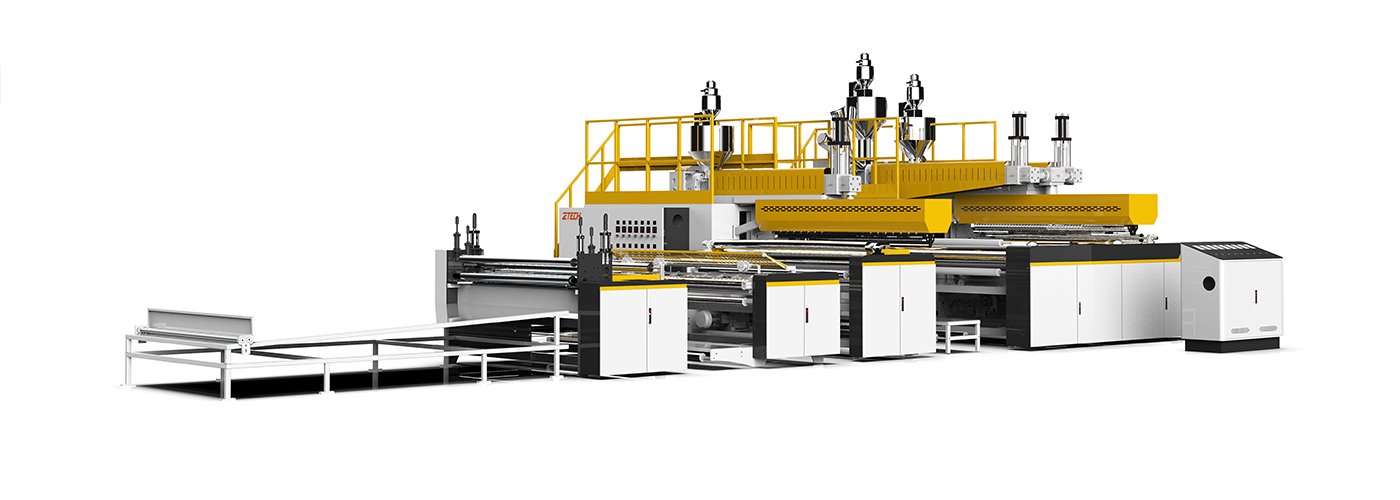

As a professional 3-layer PP bubble sheet machine, it stands out from ordinary PE bubble film machines with its focus on thick PP bubble sheet production. To address the challenges of thick PP material processing—such as ensuring sufficient extrusion volume and uniform cooling—our machine adopts a high-low dual T-die design and a large 365mm diameter bubble roller. The high-low dual T-die optimizes material flow for thick PP layers, ensuring stable extrusion volume and consistent thickness of the 3-layer PP structure (avoiding unevenness common in thick-film production). The 365mm diameter bubble roller, with an enhanced internal cooling system, significantly increases the contact area with the thick PP bubble sheet, accelerating heat dissipation and ensuring thorough cooling—preventing warping or deformation of the thick film and maintaining flatness.

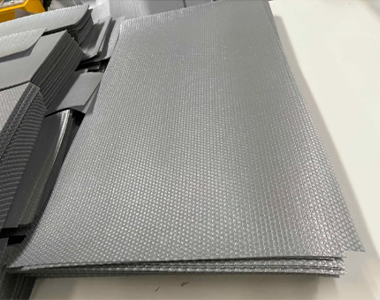

The machine supports customization of thick PP bubble sheet thickness (ranging from 3mm to 15mm, thicker than ordinary PE bubble film) and bubble size (8mm-25mm), adapting to different protective strength needs. It also integrates a stable traction system to handle the heavier thick PP material, ensuring smooth production without film breakage. Compared to PE materials, the PP bubble sheets produced by this machine have higher rigidity and wear resistance—meeting the "one-time use, strong protection" demand for temporary decoration protection.

Feature

- Specialized 3-layer thick PP production: Focuses on thick PP bubble sheets (3mm-15mm), distinguishing from ordinary thin PE bubble film machines and meeting high-rigidity protection needs.

- High-low dual T-die: Optimizes material flow for thick PP, ensuring stable extrusion volume and uniform thickness of the 3-layer structure—solving thick-film unevenness issues.

- 365mm large-diameter bubble roller: Equipped with enhanced cooling system, increases cooling contact area, ensures thorough cooling of thick PP sheets, and maintains product flatness.

- 100% PP material compatibility: Adopts PP-optimized screw design, ensuring full plasticization of PP material, enhancing the bubble sheet’s rigidity and wear resistance.

- Customizable specifications: Supports adjustment of thick PP bubble sheet thickness (3mm-15mm) and bubble size (8mm-25mm), adapting to diverse temporary protective scenarios.

- Stable traction system: Designed for heavier thick PP material, ensures smooth traction and production without film breakage, improving production efficiency.

Technical Parameters

| Model | ZT150-PP PP Bubble Sheet Machine |

| Layer | 5 |

| Raw materials | PP/PE/ recycle material |

| Maximum width (mm) | 1540 |

| Effective width after trimming (mm) | 1500 |

| Speed (m/hr) | 800m/hr-3000m/hr |

| Production Capacity (kg/hr) | 200kg/hr-400kg/hr |

| Range of film thickness (g/m2) | 30g/sm-800g/sm |

| Main screw diameter (mm) | Φ90mm+Φ80mm |

| Secondary screw diameter (mm) | Φ75mm |

| Power of main motor (kW) | 45KW+30KW |

| Power of secondary motor (kW) | 22KW |

| Power of vacuum pump (kW) | 3.0KW |

| Maximum rolling diameter (mm) | Φ1000mm(Can be customized upon requested) |

| Power Supply | 380V,50HZ,3 PHASES(Can be customized according to different countries) |