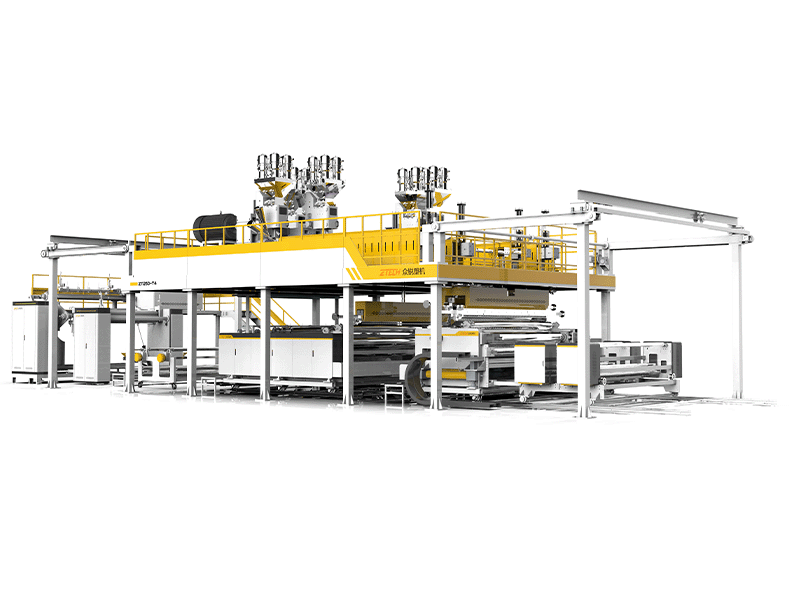

Description

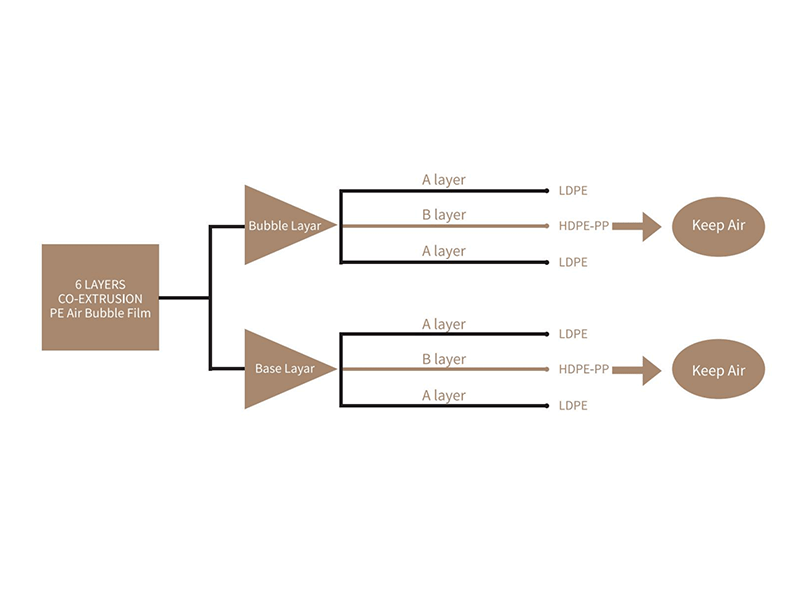

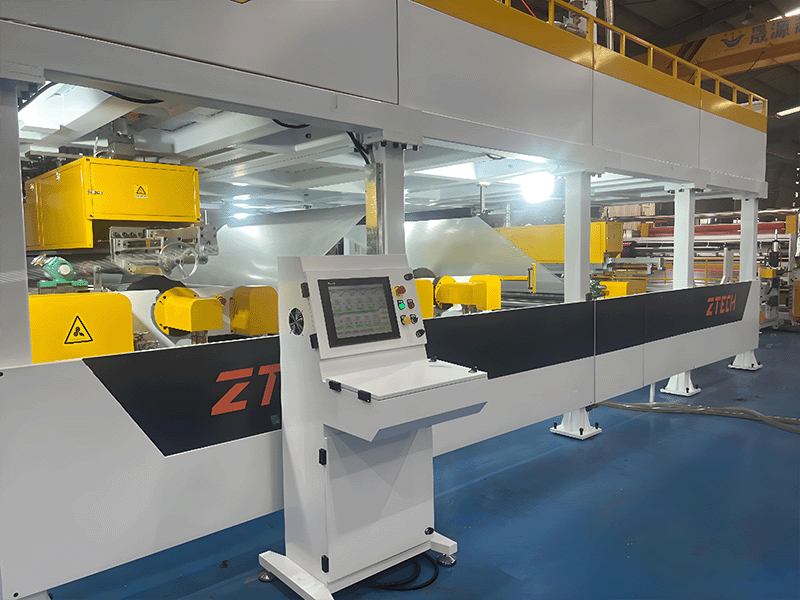

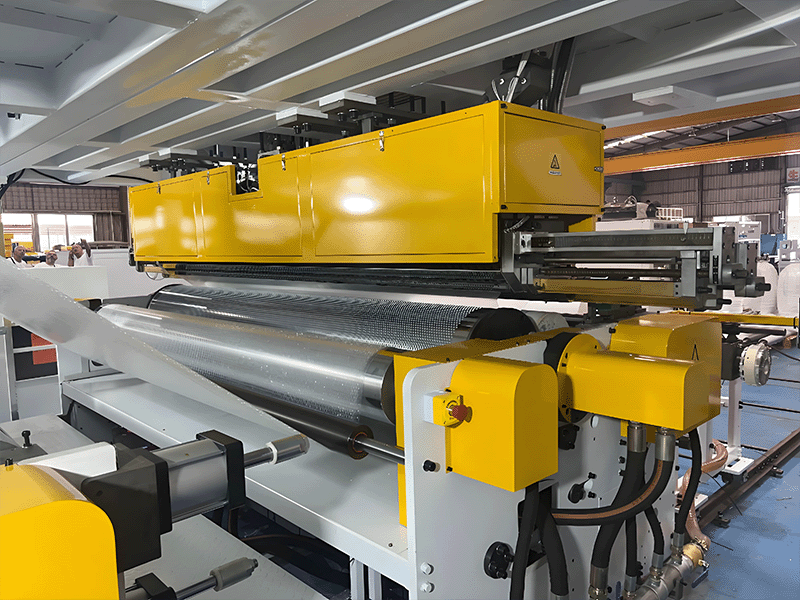

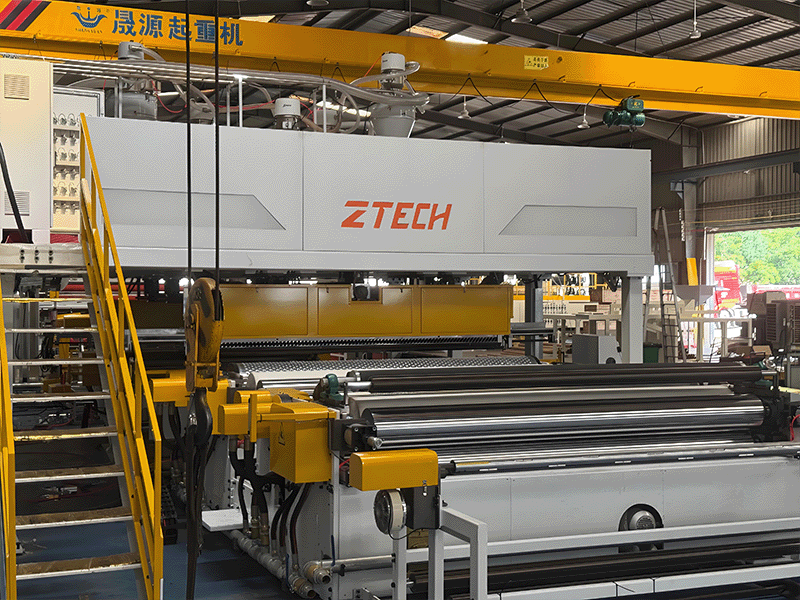

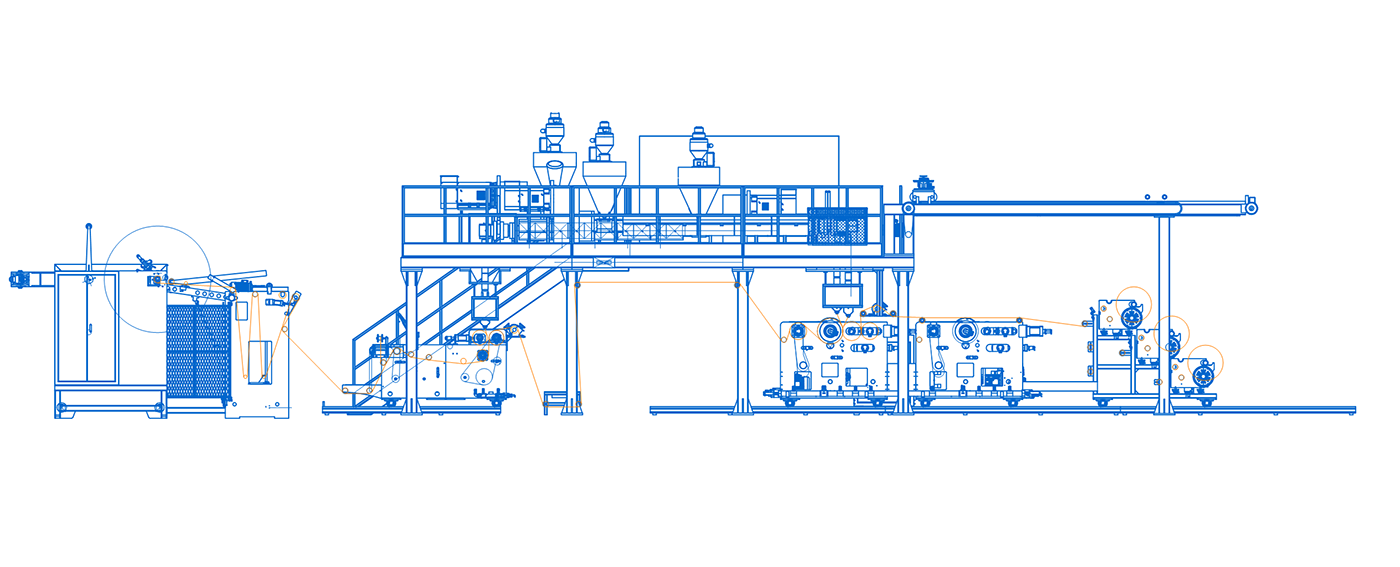

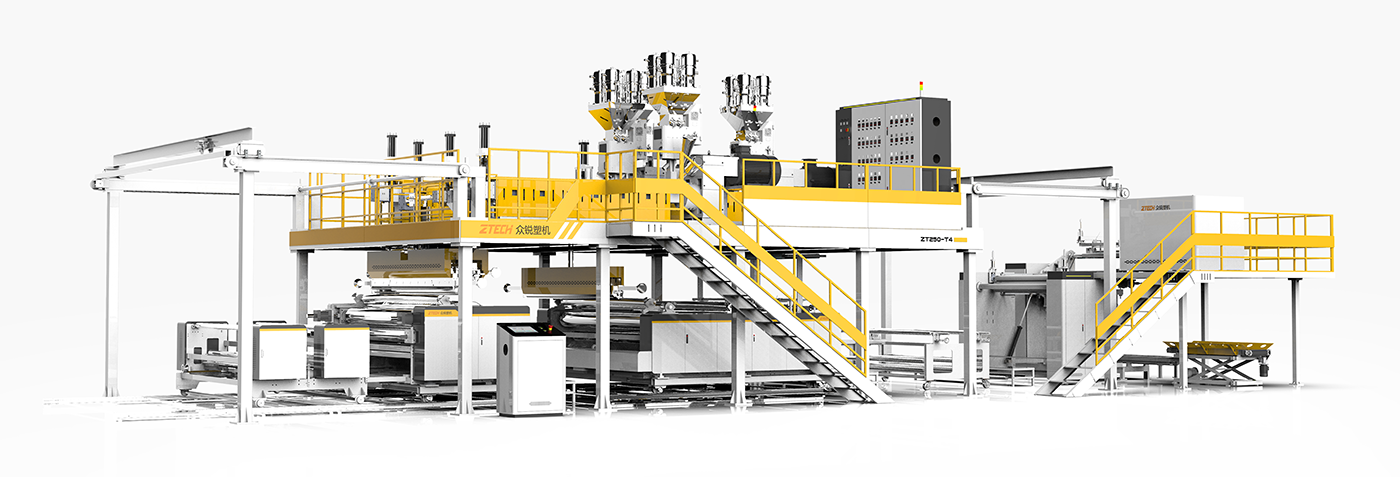

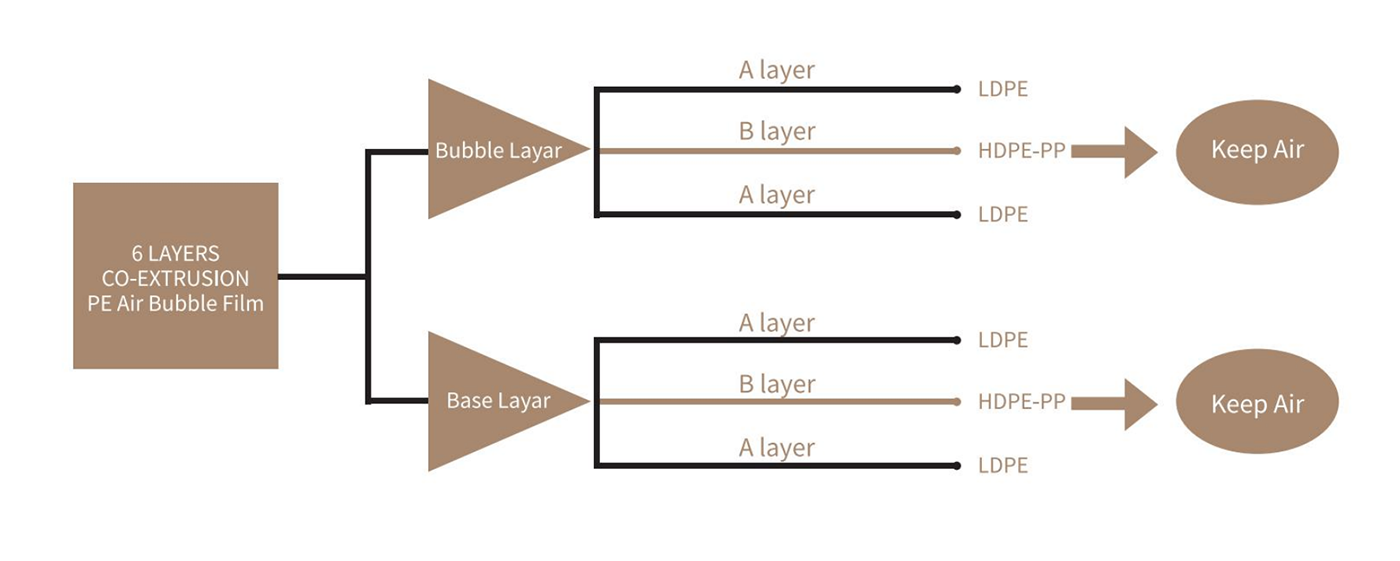

Our company’s technical department successfully developed this ABA air bubble film machine in 2016, marking a new breakthrough in bubble film production. Unlike ordinary bubble film machines, it adopts a "four screws + two dispensers" configuration to independently control the thickness and flow rate of each layer in the 3-in-1 structure (bubble layer and base layer, each with PE + PP/HDPE + PE). This design not only ensures bubble film stability but also significantly enhances toughness and durability—addressing the core demand for rigid, good-quality materials in express bag manufacturing.

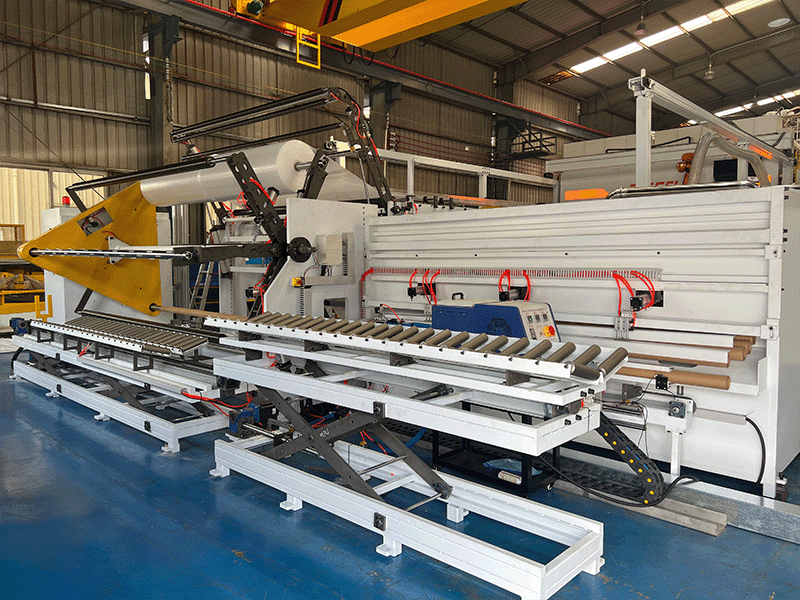

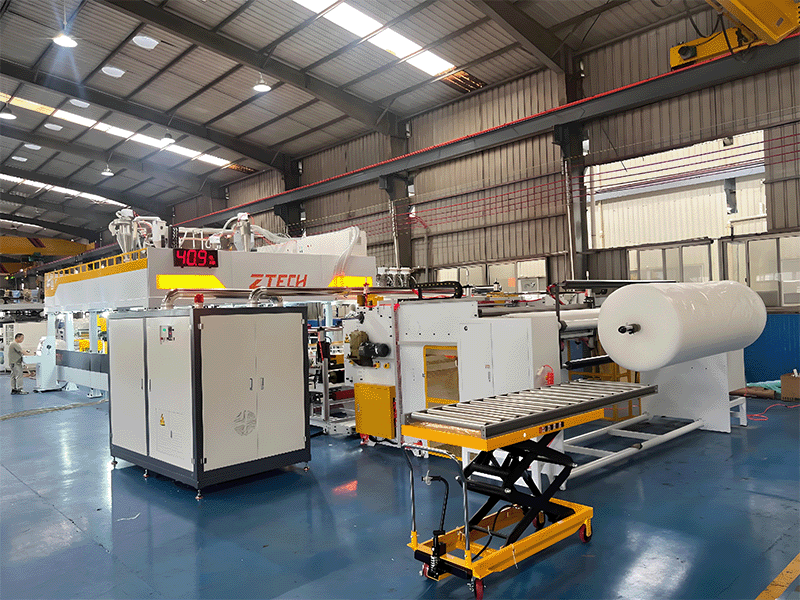

In 2023, our team overcame the ABA machine’s capacity bottleneck, doubling the original in-line production speed from 50 meters per minute to 100 meters per minute. This upgrade boosts efficiency while retaining key advantages: it supports increasing the ratio of HDPE/PP (up to 100%) in the formula to improve product hardness, perfectly matching express bag production requirements. Additionally, the bubble wrap machine integrates in-line express bag production capabilities, eliminating the need to purchase additional PE film and effectively reducing overall production costs for customers.

The machine also ensures the produced ABA bubble film outperforms conventional film in pressure tolerance, humidity resistance, vibration resistance, and abrasion resistance—making it suitable for high-demand packaging scenarios beyond express bags.

Features

- Unique 3-in-1 co-extrusion structure: Bubble layer and base layer are each merged from three layers (PE + PP/HDPE + PE), enhancing product hardness and handfeel—ideal for bubble film-aluminum film express bags.

- Independent layer control: Equipped with four screws and two dispensers, this bubble film machine independently adjusts the thickness and flow rate of each layer, enabling flexible formula adjustments (e.g., up to 100% HDPE/PP ratio).

- Enhanced product performance: Compared to ordinary bubble film, the ABA bubble film has significantly improved toughness, durability, pressure tolerance, humidity resistance, vibration resistance, and abrasion resistance.

- High in-line efficiency: Upgraded in 2023 to reach 100 meters per minute in-line production speed—doubling efficiency and meeting large-volume express bag manufacturing needs.

- Cost-saving integration: Supports in-line express bag production, eliminating the need for additional PE film purchases and reducing material and processing costs.

- Proven technical strength: Developed in 2016 with subsequent speed upgrades, providing optimized configurations for European customers and earning high satisfaction in the global market.

Technical Parameters

| Model | ZT200-5COX ABA co extrusion bubble film machine |

| Layer | 5 |

| Raw materials | LDPE / LLDPE / PP/ HDPE/ recycled material |

| Maximum width (mm) | 2040 |

| Effective width after trimming (mm) | 2000 |

| Speed (m/hr) | 1000m/hr-4800m/hr |

| Production Capacity (kg/hr) | 150kg/hr-700kg/hr |

| Range of film thickness (g/m2) | 2 layers: 25g/sm-300g/sm 3 layers: 45g/sm-400g/sm |

| Main screw diameter (mm) | Φ120mm + Φ90mm and Φ100mm + Φ85mm |

| Secondary screw diameter (mm) | Φ80mm |

| Power of main motor (kW) | 75kw +45kw and 55kw +37kw |

| Power of secondary motor (kW) | 30kw |

| Power of vacuum pump (kW) | 4 |

| Maximum rolling diameter (mm) | Φ1000mm (Can be customized upon requested) |

| Power Supply | 380V,50HZ,3 PHASES(Can be customized according to different countries) |