Description

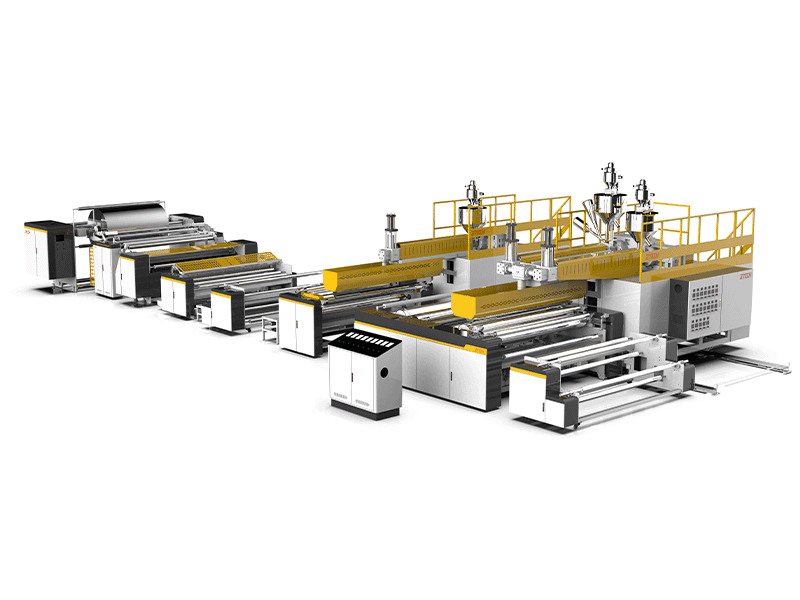

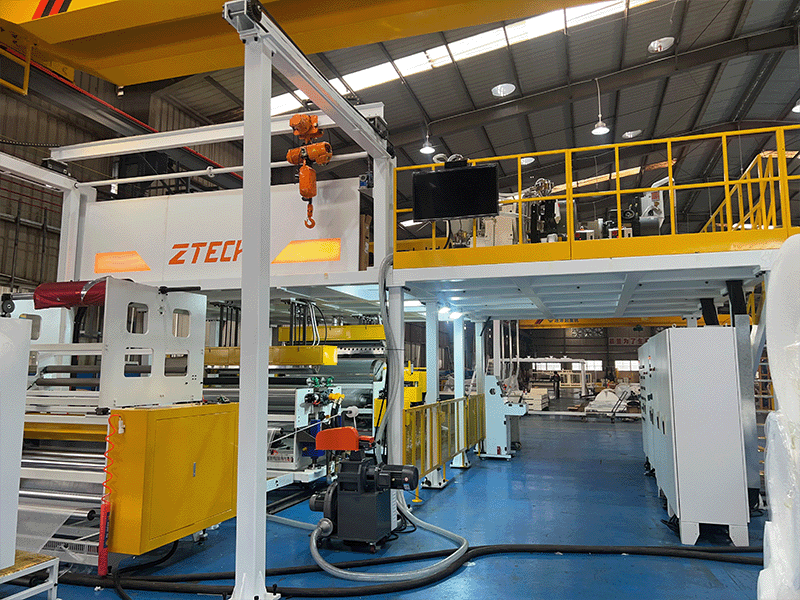

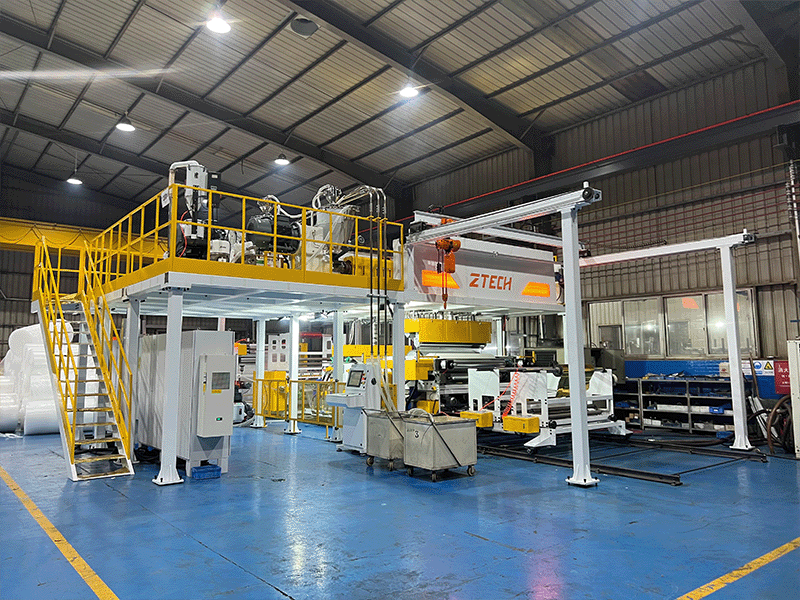

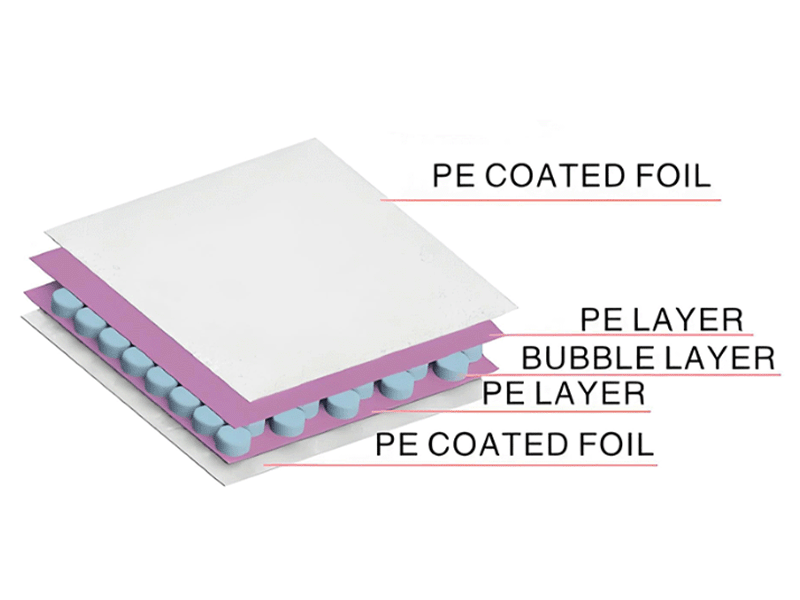

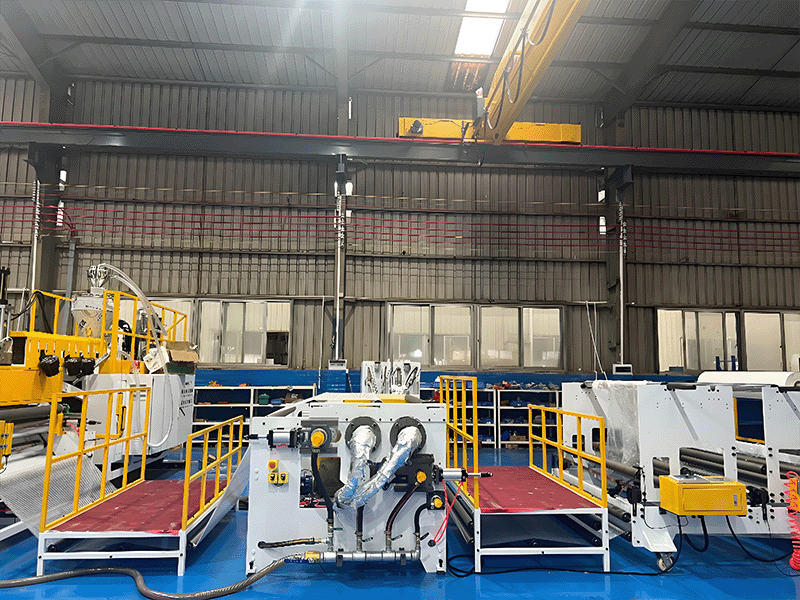

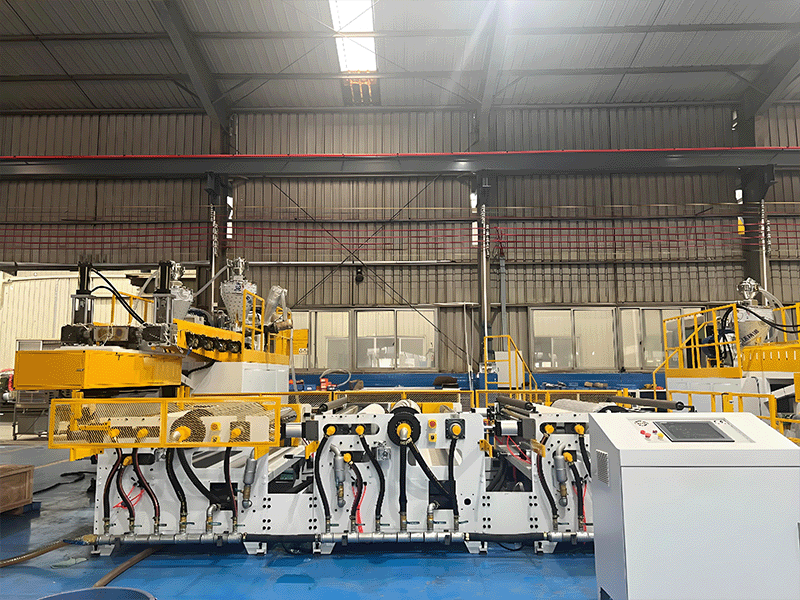

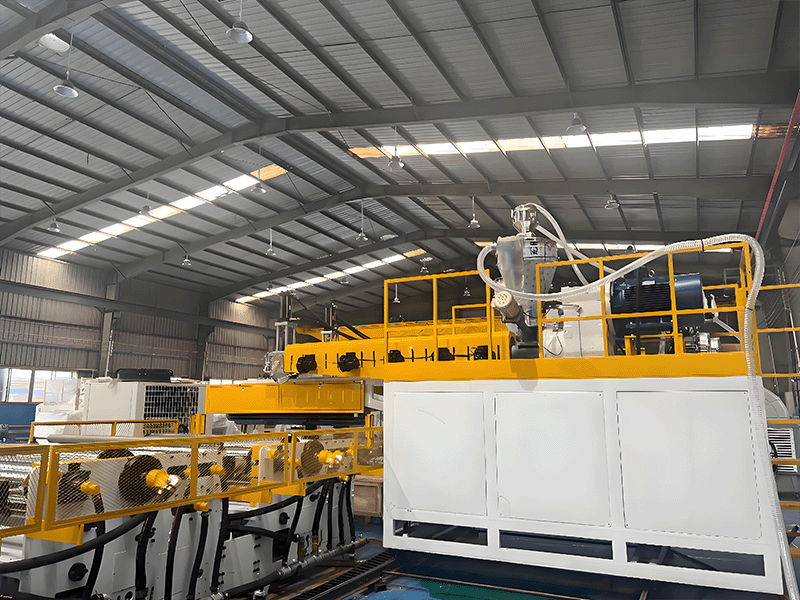

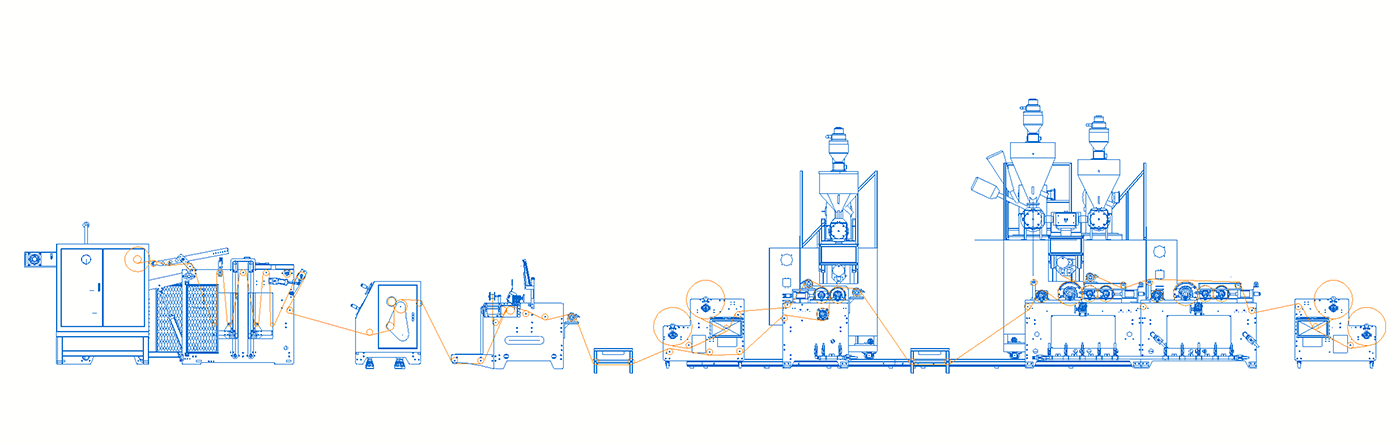

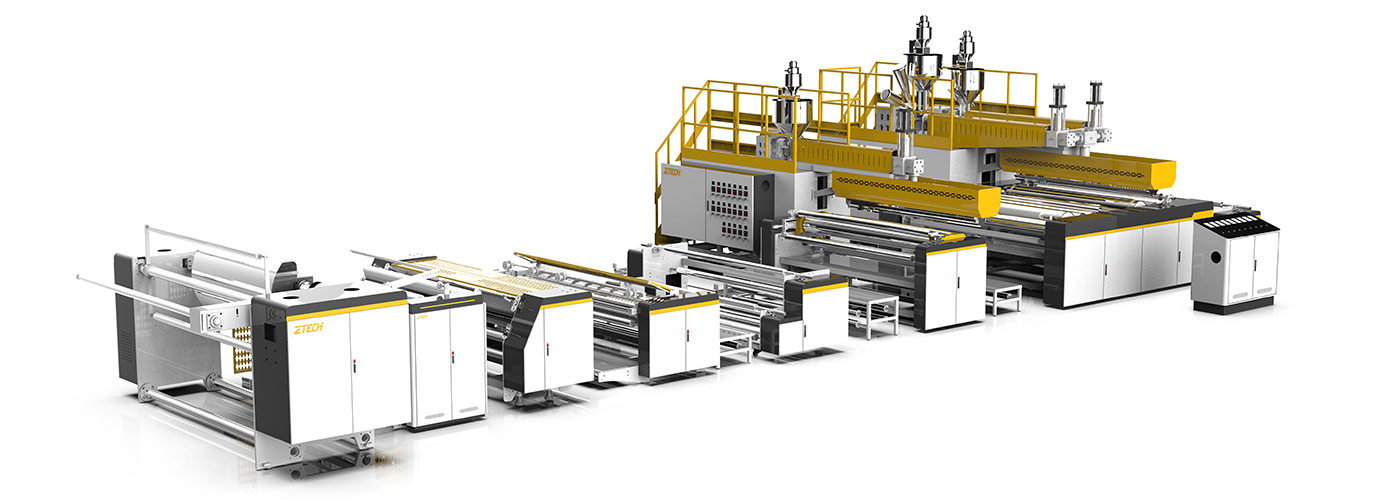

As a high-performance 5-layer air bubble film machine, it stands out for its integrated lamination function—no need for separate auxiliary equipment to composite PE-coated materials with bubble film, directly forming a 5-layer structure. Unlike traditional machines limited to single bubble film production, this bubble wrap machine uses a multi-group extrusion and lamination system, which can independently control the thickness, tension and bonding strength of each layer (including base PE layer, bubble layer, and composite material layer).

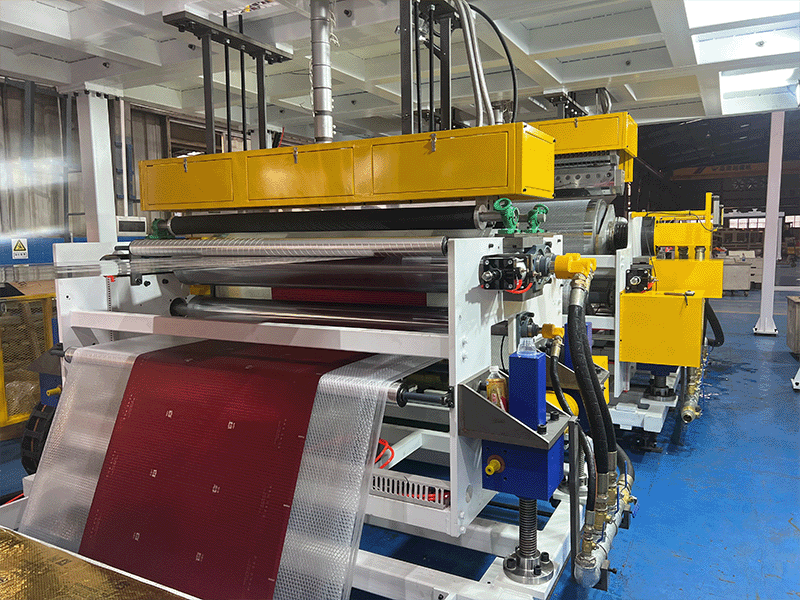

It supports customized composite combinations, such as "PE Layer + Bubble Layer + PE Layer + Kraft Paper + PE Layer" or "PE Layer + Bubble Layer + PE Layer + Aluminum Foil + PE Layer", and is compatible with common PE-coated composite materials on the market. The machine is equipped with a precision pressure-adjustable lamination roller group and a constant-temperature heating system, ensuring firm bonding between bubble film and composite materials without wrinkles or delamination. It also retains optional configurations like in-line recyclers and automatic winding units, adapting to both small-batch test production and large-scale continuous operation.

Feature

- Multi-layer & multi-material compatibility: This bubble film machine freely switches between 2-layer/3-layer pure bubble film and 5-layer composite bubble film, supporting lamination with Aluminum Foil, Kraft Paper, EPE Foam, HDPE Film and other PE-coated materials.

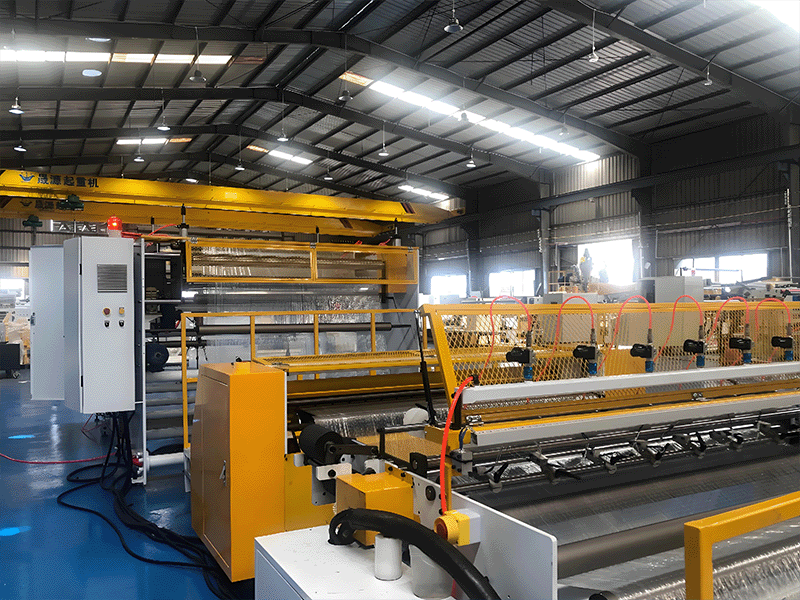

- In-line lamination efficiency: Integrates extrusion and lamination functions, eliminating the need for secondary processing. Compared with split machines, it shortens production time by 30% and reduces material waste caused by transfer.

- Precise layer control: Each of the 5 layers can be independently adjusted for thickness and material formula. For example, the composite layer can use functional materials (such as moisture-proof Kraft Paper, heat-insulating Aluminum Foil) while ensuring the bubble layer maintains shock absorption performance.

- Stable lamination quality: Equipped with pressure-adjustable lamination rollers and constant-temperature heating system, the bonding strength between bubble film and composite materials reaches ≥3N/25mm, avoiding delamination during winding and transportation.

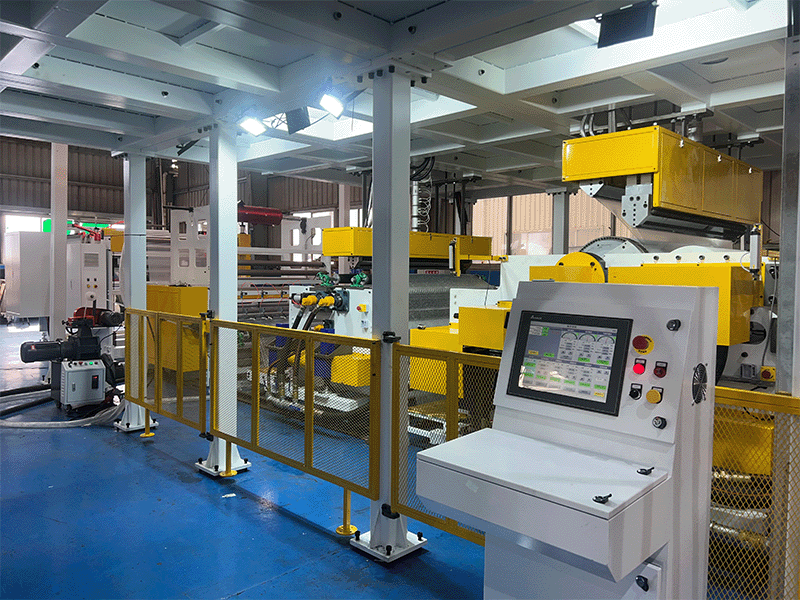

- Safety & intelligence: Adopts touch screen control system to monitor lamination temperature, extrusion speed and layer tension in real time; emergency stop button and protective guardrails ensure operator safety during the operation of the air bubble film machine.

- Durable core components: The lamination roller is made of wear-resistant chrome-plated material, and the bubble forming cylinder is equipped with a vacuum stabilization system, prolonging the service life of the bubble wrap machine and reducing maintenance frequency.

Technical Parameter

| Model | ZT300-5T Air Bubble Film Twin Screw Extruder |

| Layers | 5 |

| Raw Material | LDPE / LLDPE / PP/ HDPE/ recycled material |

| Maximum width (mm) | 3040 |

| Effective width (after edge timming, mm) | 3000 |

| Speed (meters per hour) | 800m/hr-3000m/hr |

| Production Capacity (kg/hr) | 150kg/hr-400kg/hr |

| Range of film thickness (g/m2) | 2 layers: 25g/sm-500g/sm 3 layers: 45g/sm-800g/sm |

| Main screw diameter (mm) | Φ100mm+Φ85mm |

| Secondary screw diameter (mm) | Φ80mm |

| Power of main motor(kW) | 55KW+37KW |

| Power of secondary motor(kW) | 30KW |

| Power of vacuum pump | 3.0KW |

| Unwinder rack | 2 sets with maximum diameter of Φ500mm |

| Lamination materials | aluminum foil, film laminating kraft paper, EPE foam, PE film, etc. |

| Maximum winding diameter | Φ1000mm (Can be customized upon requested) |

| Power supply(volt) | 380V,50HZ,3 PHASES (Can be customized for different countries) |