Description

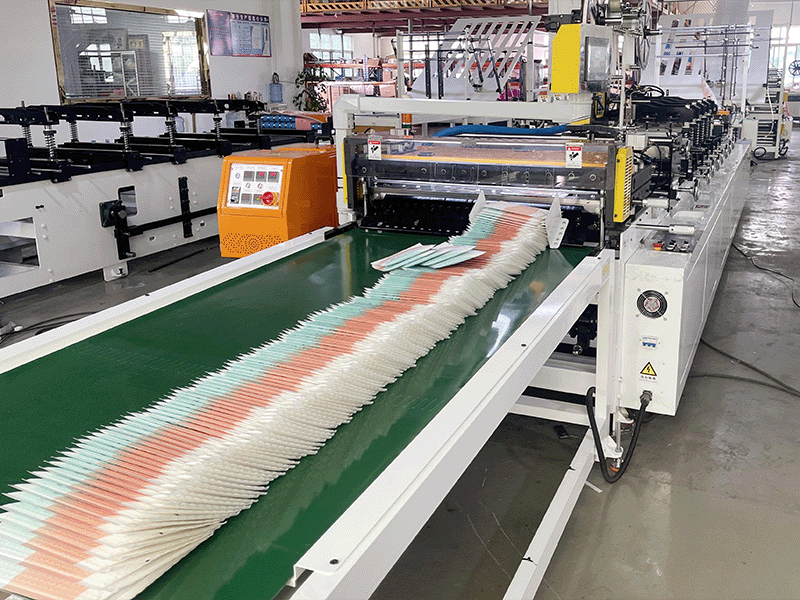

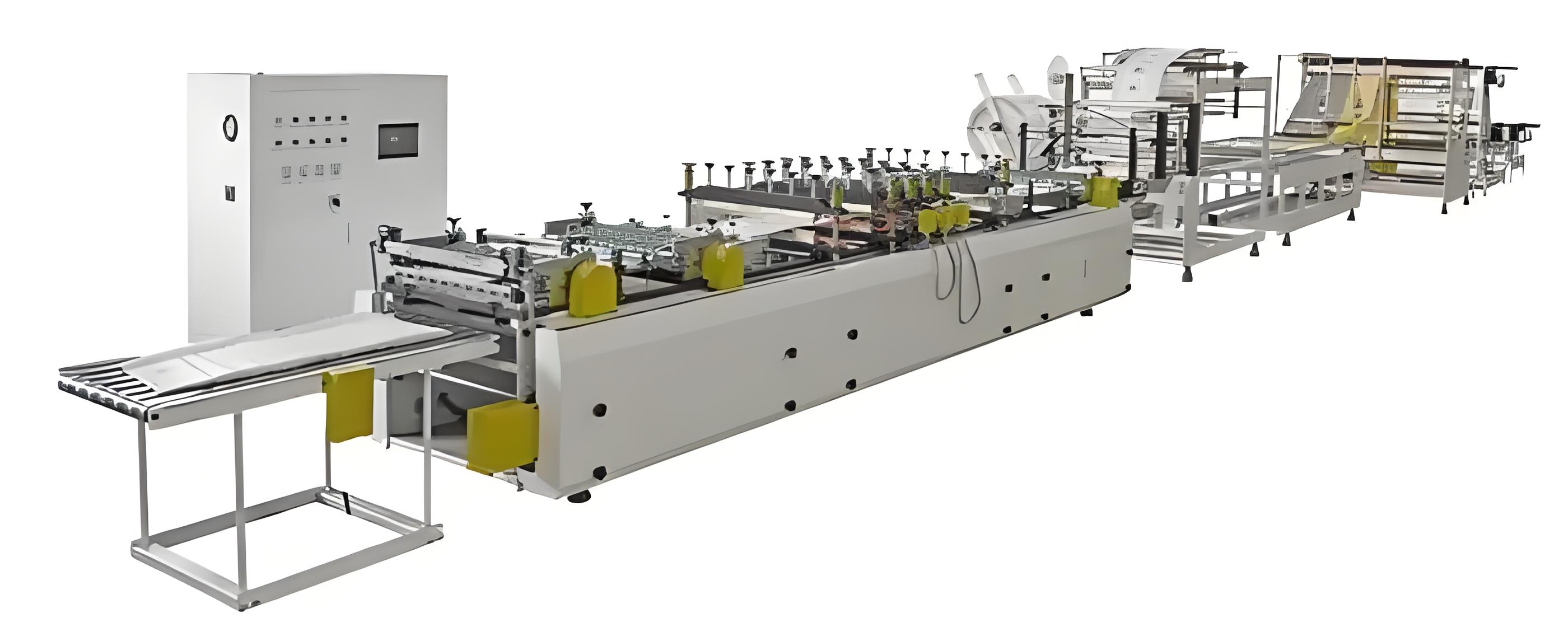

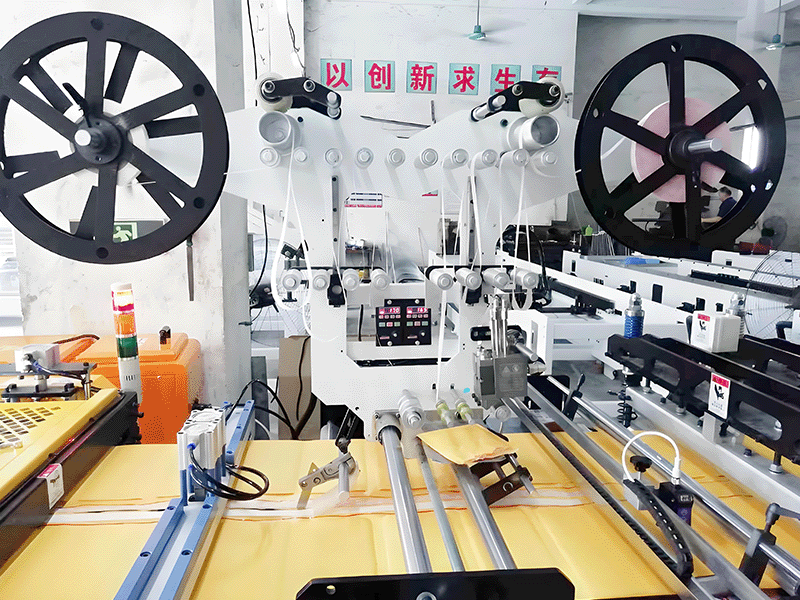

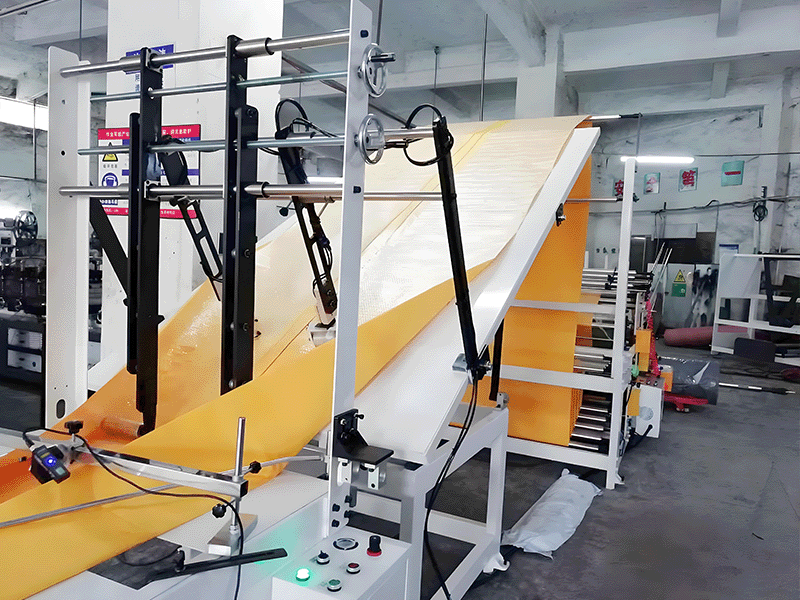

As a multi-functional air bubble film bag machine (laminated with kraft paper, PE film, aluminum foil), it consists of three core units: bubble lamination unit, film folding unit, and edge sealing unit. First, the lamination unit bonds outer materials (kraft paper, aluminum foil, BOPP film, or pearlized film) with inner bubble film; then, the folding unit shapes the laminated film into a mailer structure; finally, the edge-sealing unit performs two-side sealing to form a tight two-seal mailer.

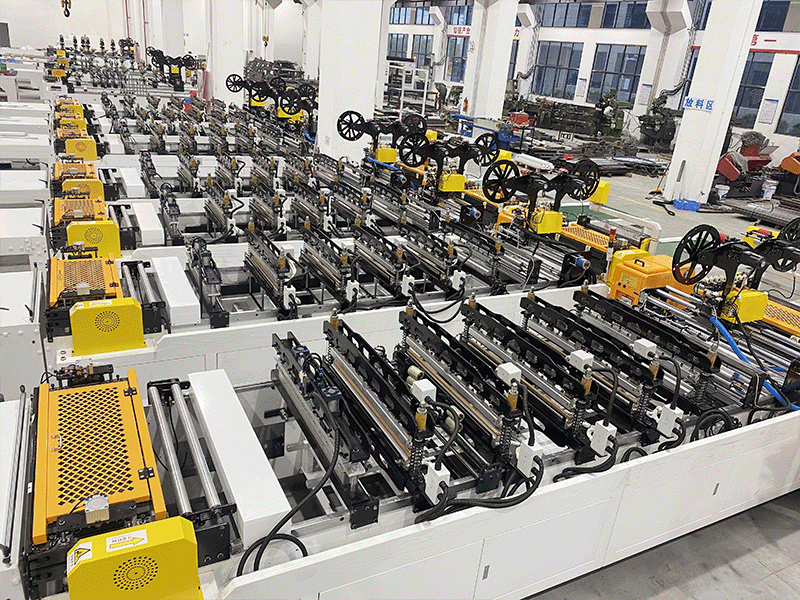

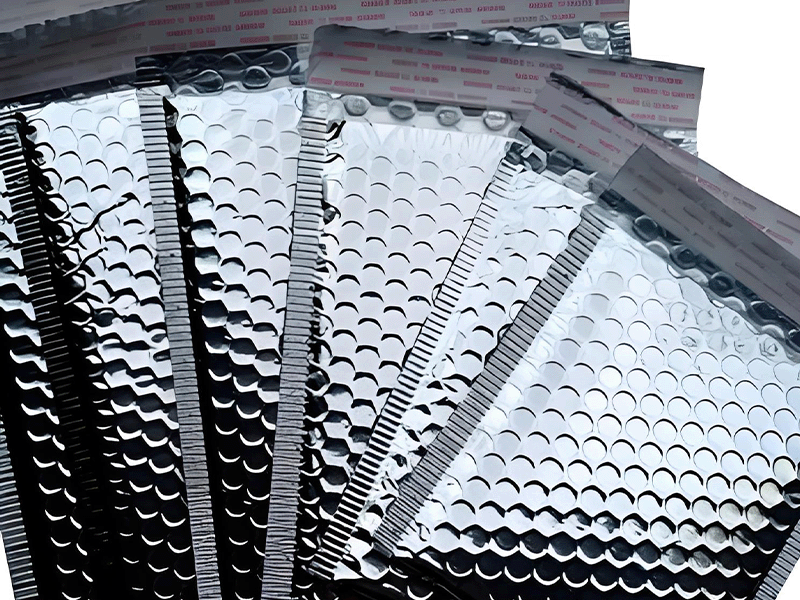

Casted frames ensure high-speed operation (max 120 mailers/min) with low noise. The advanced dual servo color tracking system enhances safety and reliability, avoiding material deviation. It can produce various bubble envelopes: kraft paper bubble envelopes (via kraft paper lamination), aluminum foil laminated bubble envelopes (as aluminum foil bubble mailer machine), and EPE foam bubble envelopes (when used as EPE foam bubble mailer machine)—meeting diverse texture and protection needs.

Feature

- Multi-material compatibility: Works as kraft paper bubble mailer machine, aluminum foil bubble mailer machine, BOPP film bubble mailer machine, and EPE foam bubble mailer machine—supports lamination with kraft paper, PE film, aluminum foil, pearlized film.

- High-efficiency production: Max speed up to 120 mailers per minute, with casted frames for low-noise, high-stability operation—meeting mass e-commerce mailing needs.

- Advanced servo control: Dual servo color tracking system ensures precise material alignment, avoiding offset and ensuring consistent mailer size/quality.

- Integrated workflow: Combines bubble lamination, film folding, and two-side sealing into one line—no separate steps, simplifying production.

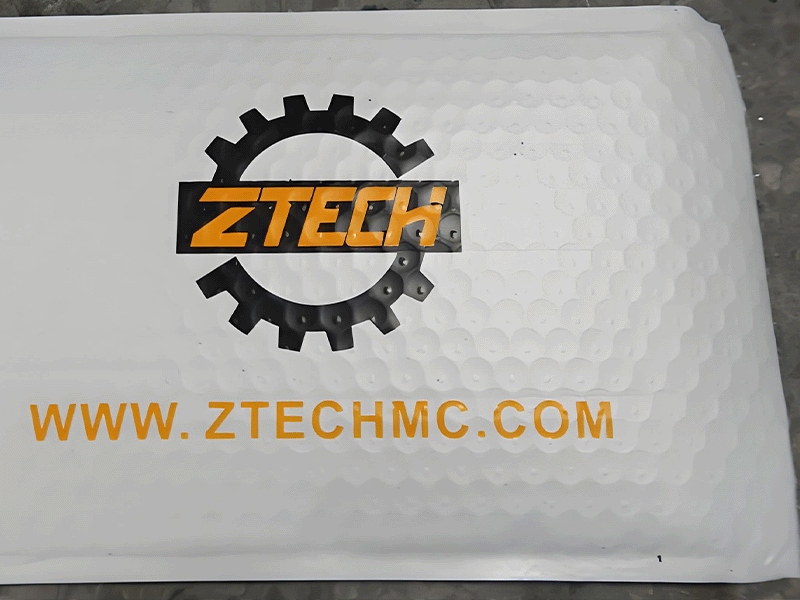

- Strong two-side sealing: Tight edge seals prevent moisture/dust intrusion, and the laminated bubble layer enhances impact resistance (protects against pressure, falling, collision).

- Versatile mailer types: Produces aluminum foil laminated, composite film, co-extrusion, kraft paper, and pearlized film bubble envelopes—adapting to different packaging scenarios.

Technical Parameters

| Production Capacity | 50-120 per minute |

| Minimum size of envelope | 100*100mm |

| Maximum size of envelope | 600*600mm |

| Power Supply | 380V, 50Hz/3 phases |

| Maximum Power | 25KW |

| Effective Power | 8-13KW |

| Machine size without Kraft paper composite rack | Length:10m; Width: 2.5m; Height: 2.8m |

| Machine size with Kraft paper composite rack | Length: 18m; Width 2.5m; Height: 2.8m |

| Weight | 6500kg |