Description

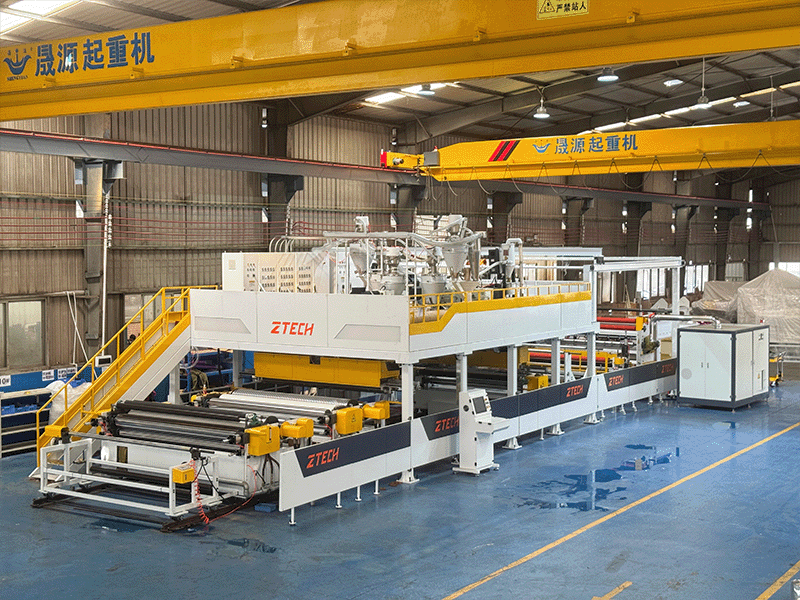

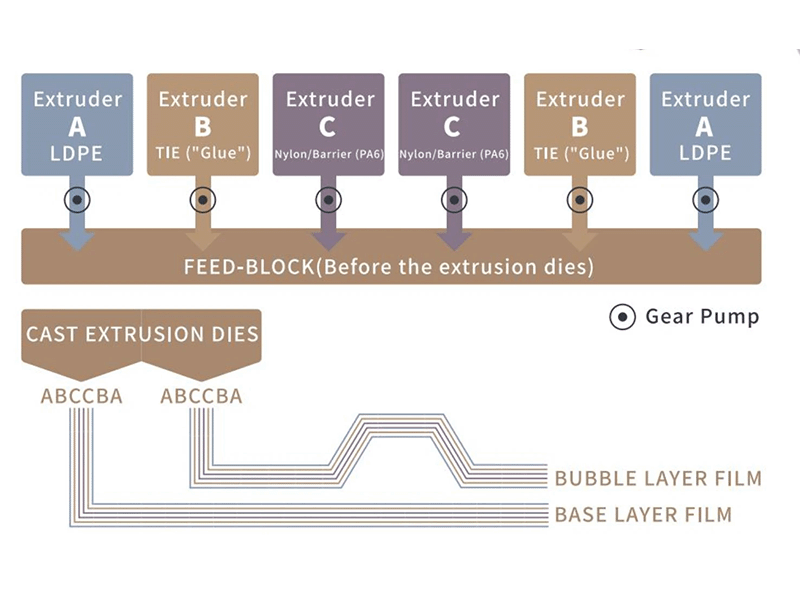

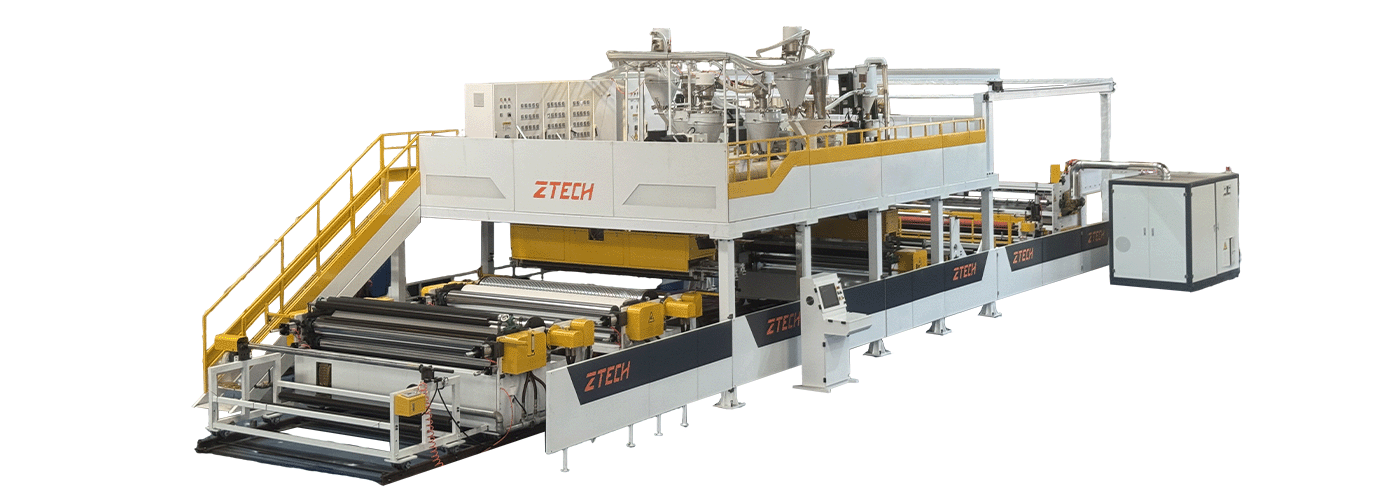

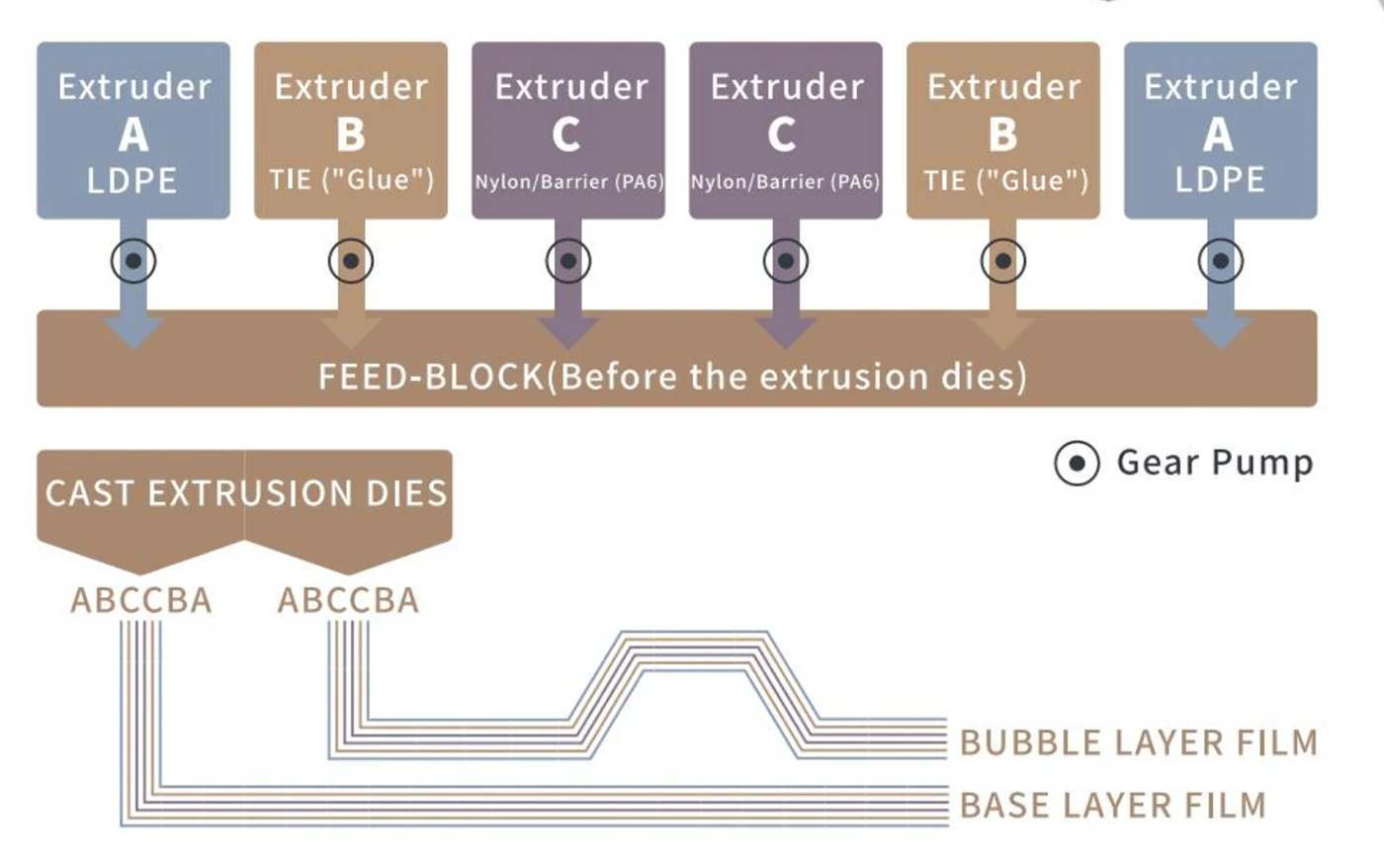

The Nylon Co-extruded Air Bubble Film Machine outperforms traditional bubble film machines in toughness and bubble durability, thanks to its unique 5-in-1 co-extrusion structure integrated with nylon layers. Unlike conventional models, it is equipped with 6 screws, enabling independent control of the thickness, material ratio and flow rate of each layer in the bubble layer and bottom layer—ensuring precise blending of nylon, TIE (adhesive) and PE materials, and stable formation of the composite structure.

Experimental data confirms its excellent air retention performance: under the same stress conditions, ordinary two-layer bubble film has a gas loss rate of up to 50% within 14 days, while the bubble film produced by this machine (combined with glue and EVA material via nylon co-extrusion technology) has a gas loss rate of only 5%. This advantage stems from nylon’s higher density than air, which slows gas leakage and extends the bubble’s effective cushioning time—perfectly addressing the core demand for long-term transportation protection. Additionally, the machine uses high-quality TIE layers to enhance bonding between nylon and PE, avoiding delamination and ensuring consistent performance of the bubble film during long-term use. It also supports flexible formula adjustments to adapt to different high-end packaging needs, such as increasing nylon content for extreme durability requirements.

Feature

- 5-in-1 nylon co-extrusion structure: Bubble layer and bottom layer each consist of PE + TIE + NYLON + TIE + PE, leveraging nylon’s high density to significantly improve bubble air retention.

- Excellent air retention performance: Produced bubble film has a gas loss rate of only 5% within 14 days (vs. 50% for ordinary two-layer film), ensuring long-term cushioning effect for long-distance transportation.

- 6-screw independent control: This bubble film machine uses 6 screws to independently regulate each layer’s parameters, enabling precise control of nylon content and ensuring stable composite structure quality.

- Strong material bonding: High-performance TIE layers enhance adhesion between nylon and PE, preventing delamination and improving the bubble film’s overall toughness and durability.

- High-end performance: The machine’s output has superior toughness and impact resistance, meeting strict quality standards for high-end product packaging.

- Material efficiency: Achieves high-quality bubble film production with less packaging material, balancing protection performance and cost control for customers.

Technical Parameters

| Model | Nylon Coextrusion Bubble Film Machine ZT185-5COX | |

| Parameter Category | Component | Specification |

| Screw Diameter (mm) | Bubble Layer Extruder | PE/EVA/NYLON: ф90mm/ф45mm/ф35mm |

| Base Layer Extruder | PE/EVA/NYLON: ф85mm/ф45mm/ф35mm | |

| Sub Extruder | ф75mm | |

| Motor (kw) | Bubble Layer Extruder | PE/EVA/NYLON: 45kw/11kw/11kw |

| Base Layer Extruder | PE/EVA/NYLON: 37kw/11kw/11kw | |

| Sub Extruder | 22kw | |

| Inverter (kw) | Bubble Layer Extruder | PE/EVA/NYLON: 45kw/11kw/11kw |

| Base Layer Extruder | PE/EVA/NYLON: 37kw/11kw/11kw | |

| Sub Extruder | 22kw | |

| Gear Box | Bubble Layer Extruder | PE/EVA/NYLON: ZT225/ZT146/ZT146 |

| Base Layer Extruder | PE/EVA/NYLON: ZT225/ZT146/ZT146 | |

| Sub Extruder | ZT180 | |

| Roller & Bubble Size | Roller Diameter | ф413mm |

| Bubble Size | ф10mmx4mm、ф25mmx10mm、ф30mmx12mm | |

| Power of vacuum pump | 3.0KW | |

| Unwinder rack | 2 sets with maximum diameter of Φ500mm | |

| Lamination materials | aluminum foil, film laminating kraft paper, EPE foam, PE film, etc. | |

| Maximum winding diameter | Φ1000mm (Can be customized upon requested) | |