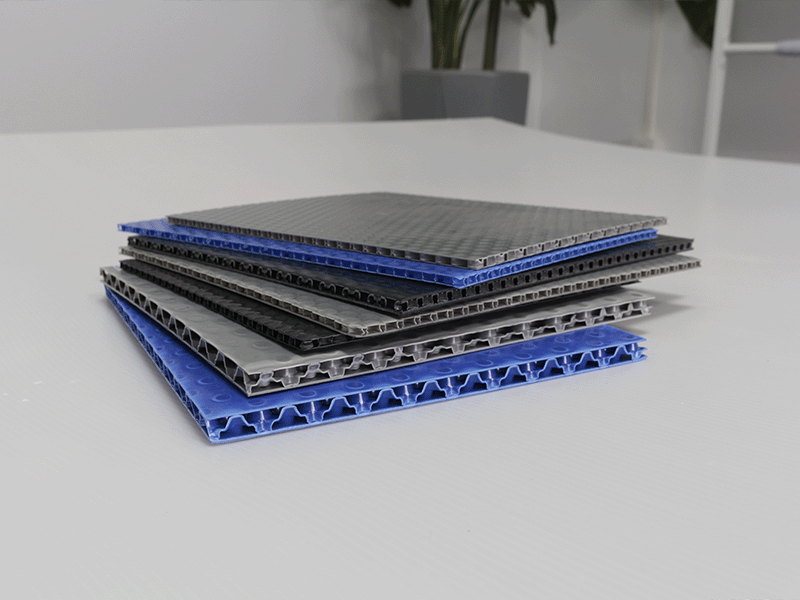

Description

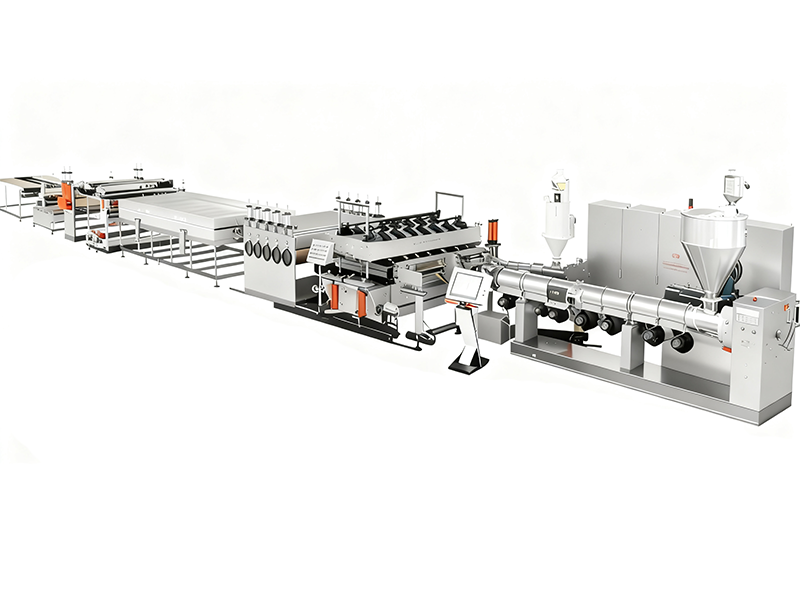

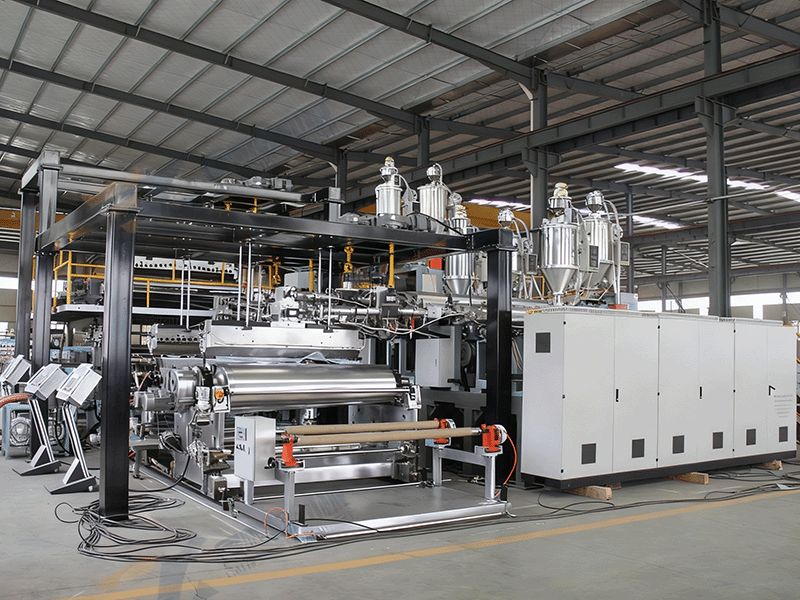

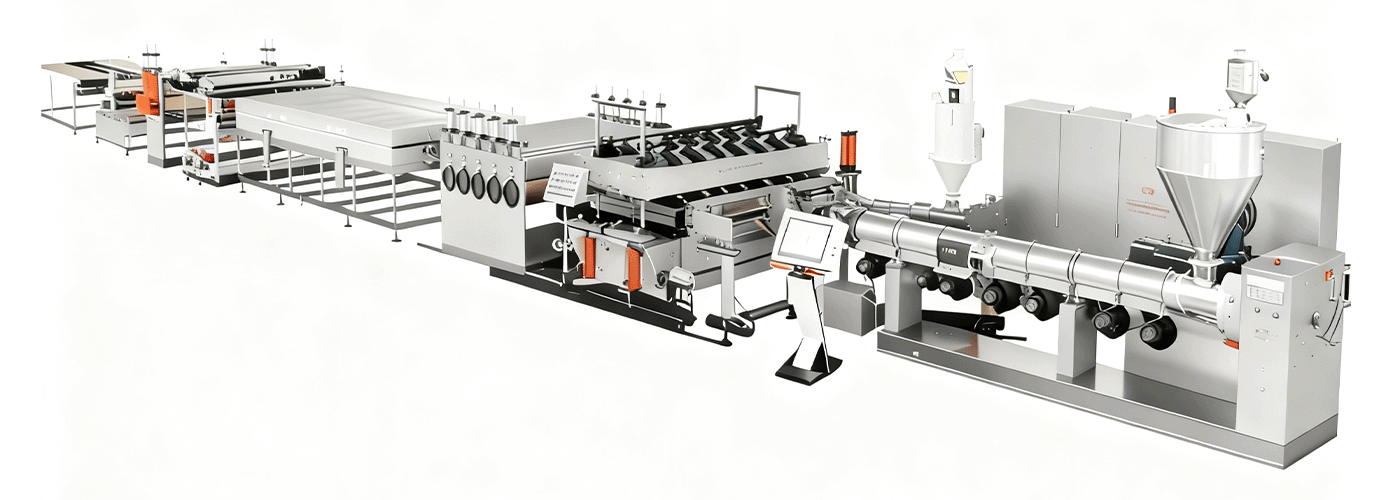

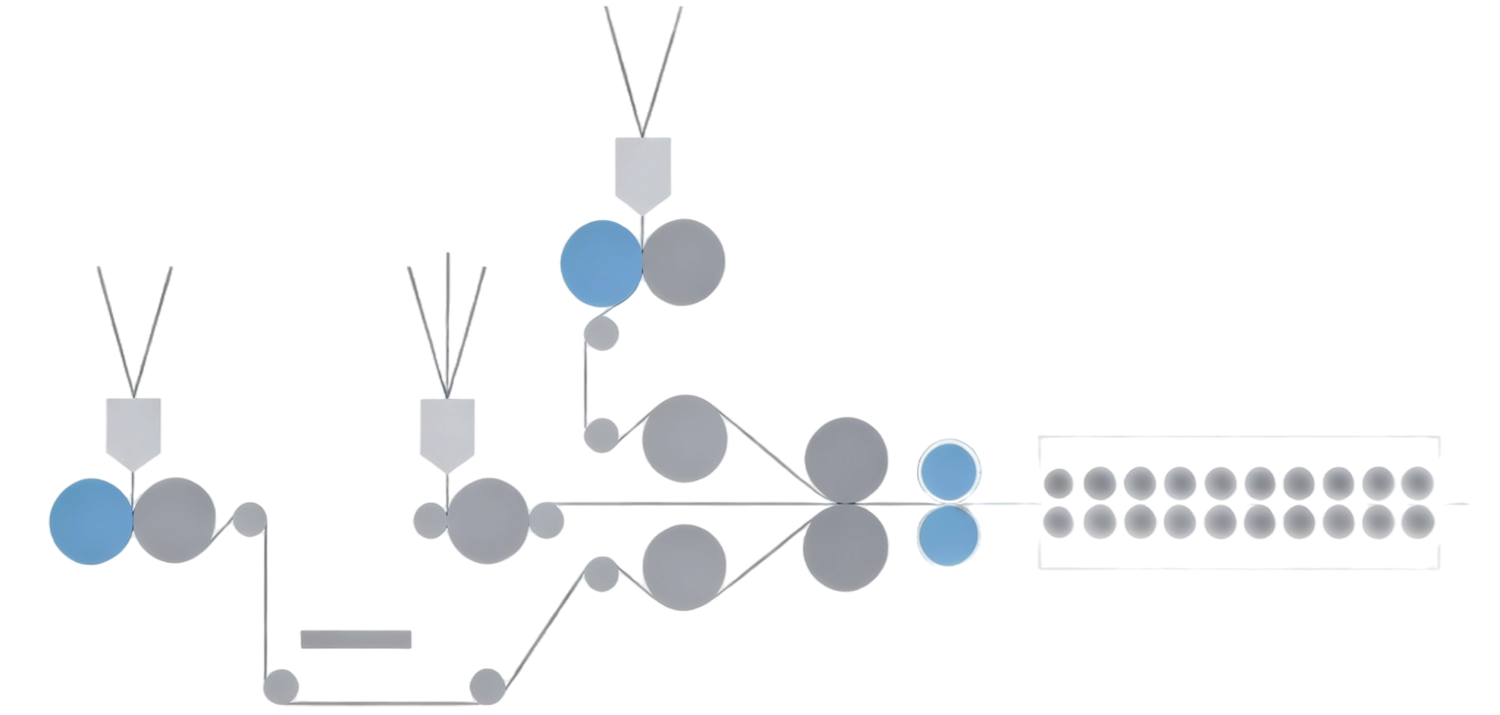

As a professional PP Honeycomb Sheet Machine, it adopts an advanced multi-unit collaborative production process to solve common pain points of traditional honeycomb sheet production, such as uneven core structure and low bonding strength. The production process starts with an automatic feeding system: raw materials (PP granules + functional masterbatches for anti-static/flame retardant) are dried and conveyed to the co-extrusion unit, which uses a multi-screw extrusion design to independently control the melting and flow of surface layers, bonding layers and honeycomb core layers—ensuring each layer’s material properties match its functional requirements.

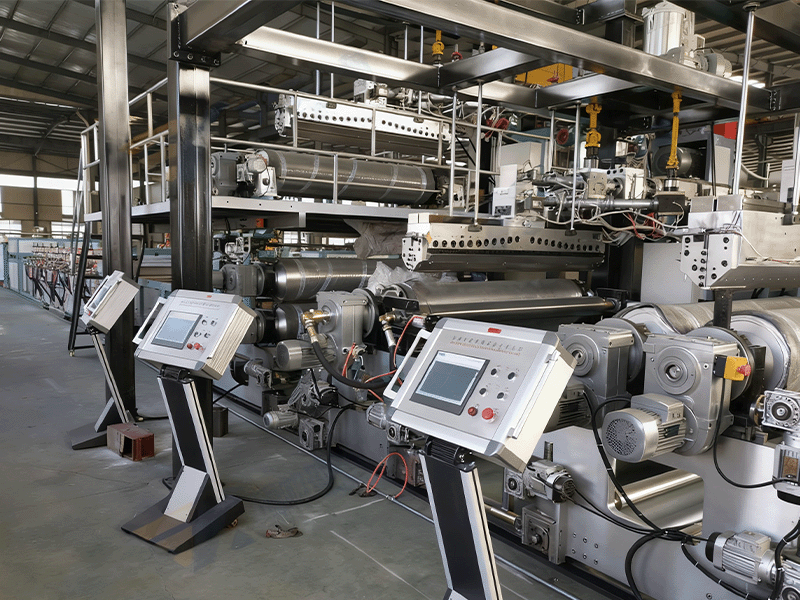

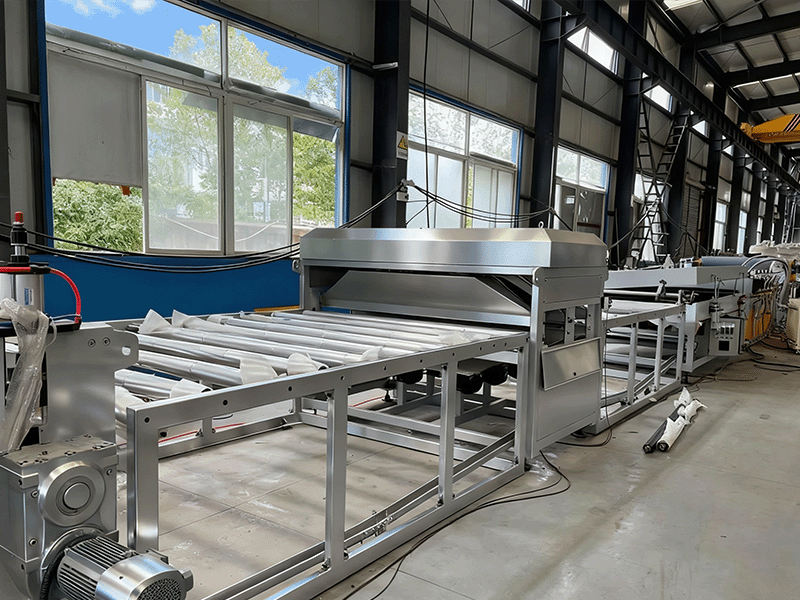

The molten material is then injected into a precision honeycomb forming mould, where it is shaped into a hexagonal honeycomb core structure under the action of vacuum adsorption and temperature control. After forming, the honeycomb core is combined with surface layers via a hot-press composite unit, with adjustable composite pressure to ensure firm bonding without delamination. A dual-stage traction system (primary for shaping, secondary for stable conveying) maintains consistent sheet thickness, while a heating-tempering unit eliminates internal stress to prevent warping. Finally, the high-precision cutting unit trims edges and cuts the sheet into customized lengths, with an optional edge recycling system to maximize material utilization.

Feature

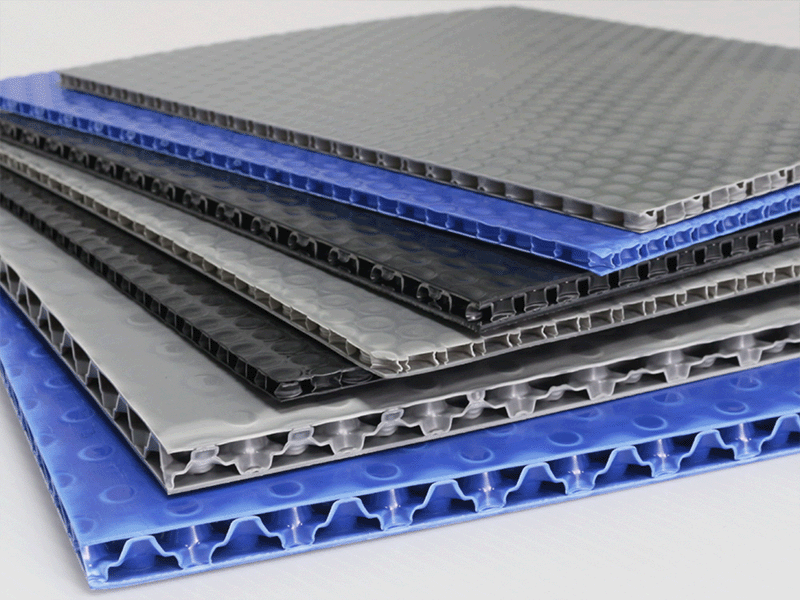

- Multi-layer co-extrusion design: Independently controls surface layers, bonding layers and honeycomb core layers, enabling targeted optimization of each layer’s strength, rigidity and functionality (e.g., anti-static surface layers + high-load-bearing core layers).

- Precision honeycomb forming: Adopts vacuum adsorption + temperature-controlled moulding, ensuring uniform hexagonal honeycomb structure, consistent cell size and high core layer integrity—enhancing the sheet’s load-bearing capacity.

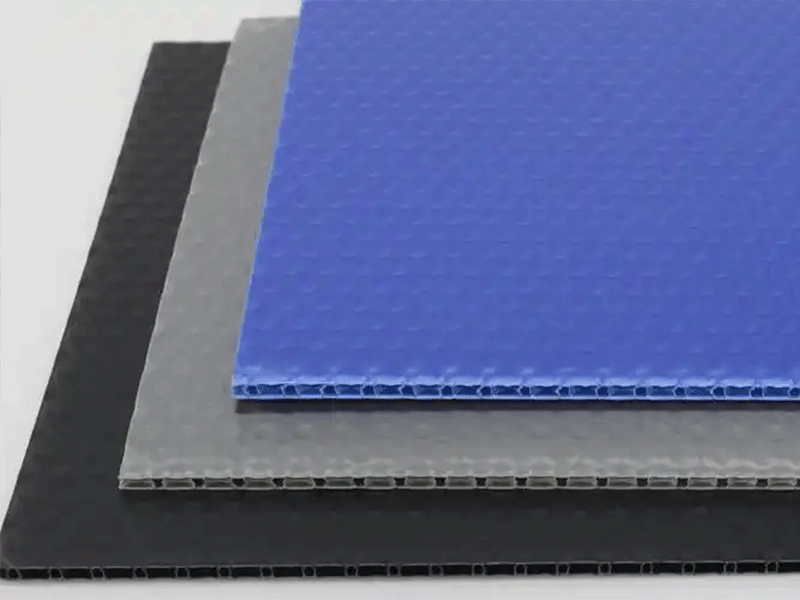

- Flexible customization: Supports adjusting sheet thickness (3-12mm), width (up to 1600mm) and gram weight (500-5000GSM); can add functional masterbatches to meet anti-static, flame-retardant or UV-resistant requirements.

- High efficiency & material saving: Equipped with an energy-saving extrusion system and optional edge recycling unit, reducing power consumption by over 20% and material waste to less than 5%—suitable for large-volume continuous production.

- Stable product performance: Dual-stage traction + heating-tempering process ensures flat sheets with no warping; the honeycomb structure provides excellent impact resistance and compression resistance, with a service life 3-5 times longer than ordinary PP flat sheets.

- Intuitive intelligent control: Equipped with a touchscreen HMI + PLC control system, realizing real-time monitoring of production parameters (temperature, speed, thickness) and automatic fault prompts—simplifying operation and reducing manual intervention.

Technical Parameters

| Item | Technical Parameters |

| Model | ZT120-PP (Six Screw Design) |

| Layer | 2-3 layers (top, bottom, and honeycomb layers formed by co-extrusion) |

| Maximum width (mm) | 1200 |

| Production capacity (kg/hr) | 100kg--Max. 380kg/hr (Note: Output depends on the thickness & width of the product) |

| Range of film thickness (g/m²) | 400-4000 |

| Screw diameter (mm) | Φ100mm + Φ55mm (with Extruder 1, Extruder 2, Extruder 3) |

| Screw length diameter ratio | PE Layer: 34:1; Coextrusion Layer: 32:1 |

| Power of main motor | 55kw+11kw (fwith Extruder 1, Extruder 2, Extruder 3) |

| Power supply(volt) | 3×380V+N+PE, 50HZ |