Description

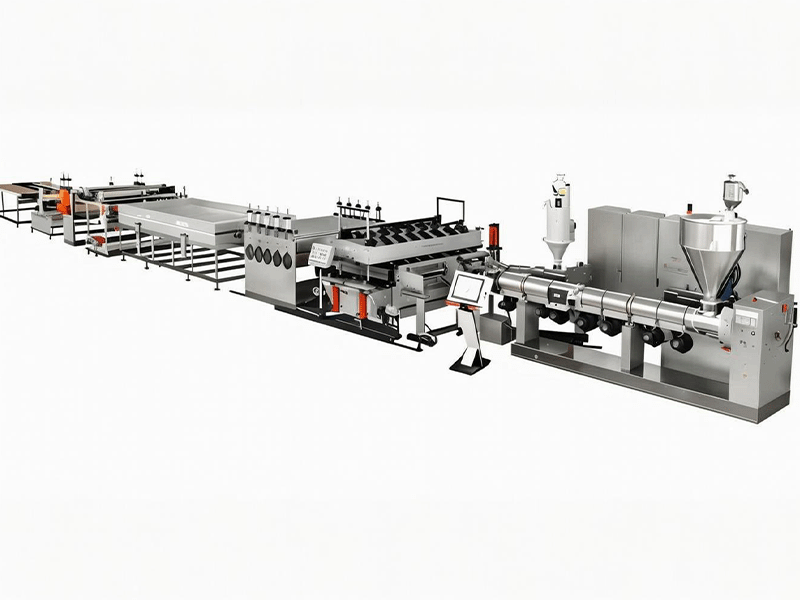

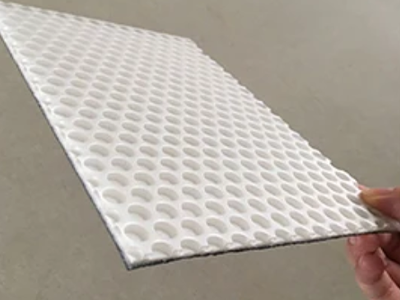

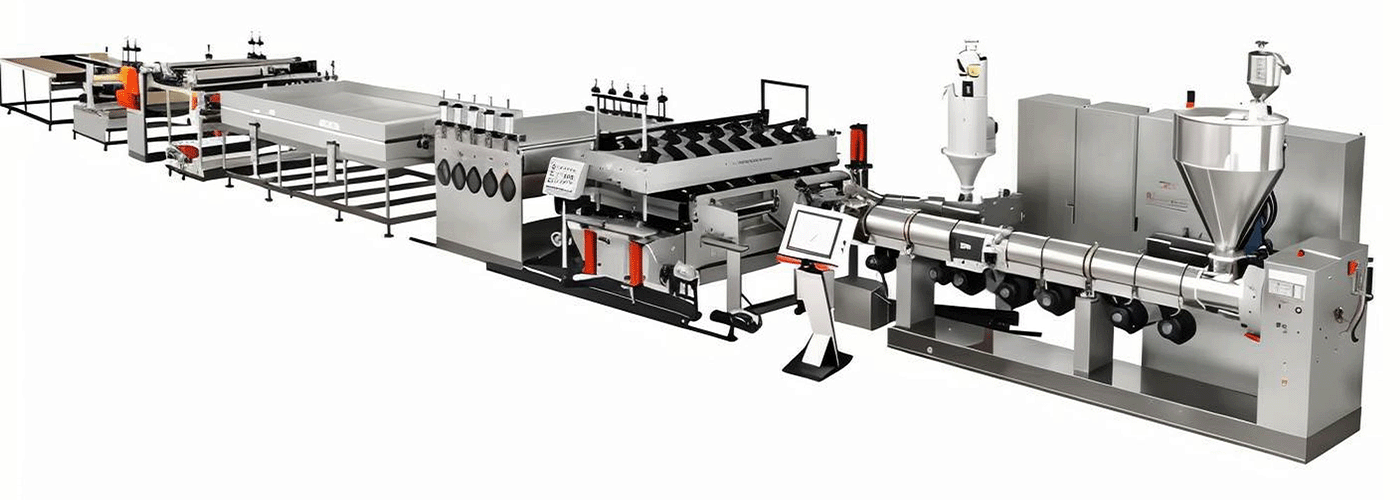

As a professional PP bubble sheet machine, PP bubble guard machine, and PP bubble board machine, this equipment adopts a 3-T-die extrusion system, dedicated to processing 100% PP raw materials into 3-layer integrated bubble sheets/boards. Unlike ordinary bubble film machines, it features a multi-stage drying unit: after the 3-layer PP bubble sheet is extruded and formed, it undergoes 3-4 rounds of precise temperature-controlled drying (adjustable from 60℃ to 80℃) to eliminate internal stress, ensuring the final PP bubble board is flat, free of warping, and maintains structural rigidity.

The machine is equipped with a high-precision servo-driven slicing system, which can cut the dried PP bubble sheet into customized lengths (ranging from 0.5m to 5m) according to customer needs, with a cutting error of less than 2mm. It supports flexible adjustment of bubble size (5mm-20mm) and sheet thickness (2mm-10mm) through the 3-T-die configuration, adapting to different application scenarios—whether it’s thick PP bubble guards for auto parts or thin PP bubble sheets for packaging. Additionally, the PP bubble board machine uses a unique screw design optimized for PP material properties, ensuring full plasticization of PP, enhancing the bubble’s pressure resistance, and making the final product "rigid yet lightweight"—a core advantage over traditional packaging materials.

Feature

- Multi-name versatility: Functions as a PP bubble sheet machine, PP bubble guard machine, and PP bubble board machine, covering multiple search needs and adapting to diverse product naming habits.

- 3-layer PP integrated structure: Produces 3-layer all-PP bubble sheets/boards via 3-T-die extrusion, ensuring excellent rigidity and impact resistance compared to single-layer or mixed-material products.

- Multi-stage drying system: Undergoes 3-4 rounds of temperature-controlled drying to make the PP bubble board flat and warp-free, maintaining structural stability in long-term use.

- Customized slicing: Servo-driven slicing system supports flexible length cutting (0.5m-5m) with high precision, meeting different application requirements for PP bubble sheets.

- Rigid yet lightweight: Optimized screw design for PP materials ensures the product is rigid enough to replace cartons while remaining lightweight, reducing transportation load.

- Waterproof performance: 100% PP material makes the PP bubble guard/b sheet/board completely waterproof, avoiding damage from moisture—solving the waterproof problem of traditional cartons.

Technical Parameters

| Model | ZT200-3PP PP Bubble Guard Machine |

| Layer | 3 |

| Raw materials | PP/ recycle material |

| Maximum width (mm) | 2040 |

| Effective width after trimming (mm) | 2000 |

| Speed (m/hr) | 800m/hr-3000m/hr |

| Production Capacity (kg/hr) | 200kg/hr-500kg/hr |

| Range of film thickness (g/m2) | 100g/sm-1000g/sm |

| Main screw diameter (mm) | Φ90mm+Φ90mm |

| Secondary screw diameter (mm) | Φ90mm |

| Power of main motor (kW) | 45KW+45KW |

| Power of secondary motor (kW) | 45KW |

| Power of vacuum pump (kW) | 3.0KW |

| Maximum rolling diameter (mm) | Φ1000mm(Can be customized upon requested) |

| Power Supply | 380V,50HZ,3 PHASES(Can be customized according to different countries) |