Description

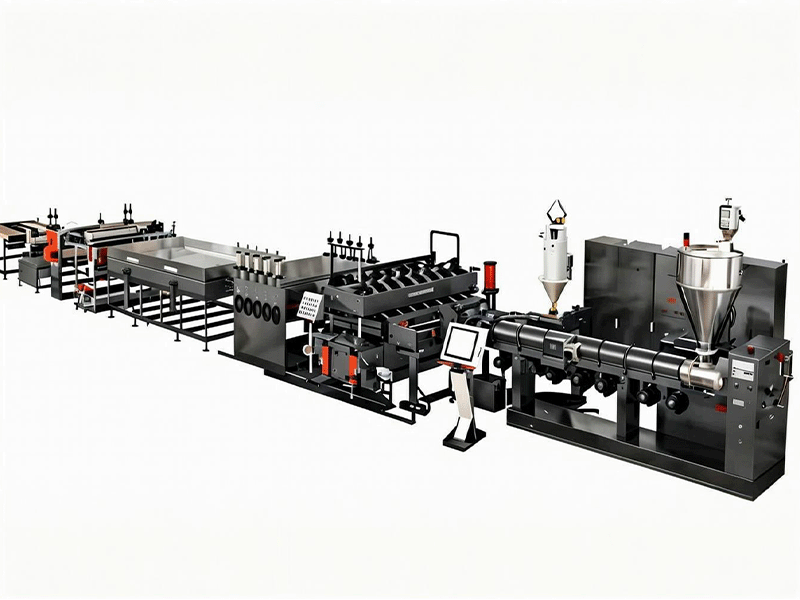

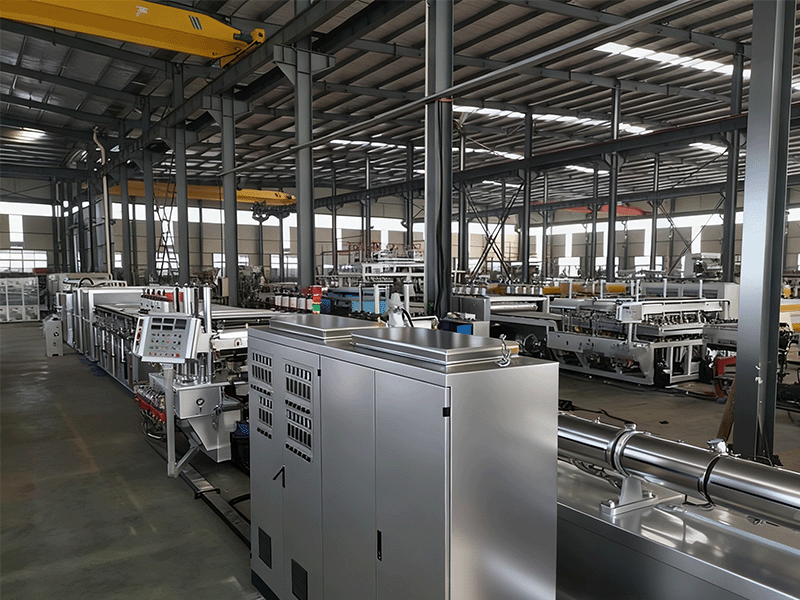

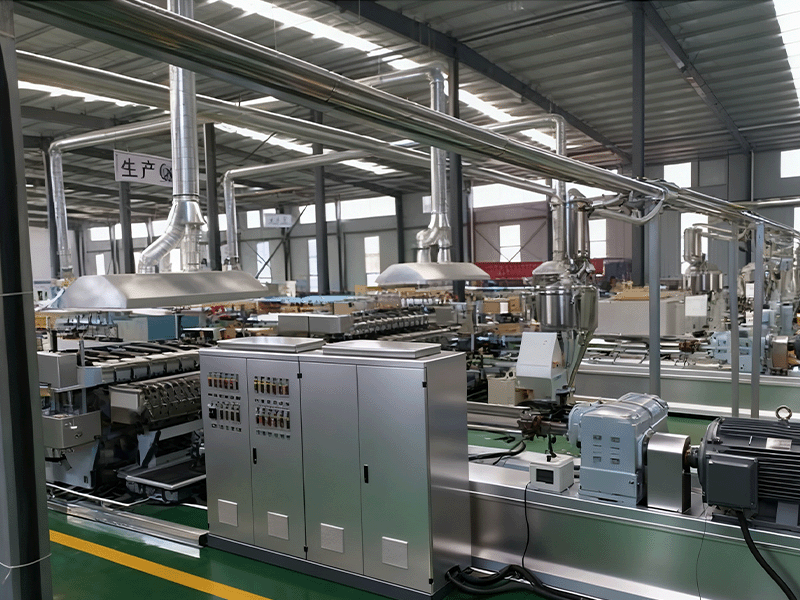

As a professional PP Hollow Board Production Line, it adopts a 13-step automated process to ensure stable production of high-quality PP hollow boards—solving common issues like warping and uneven thickness in traditional production. The line starts with a vacuum loader that automatically conveys raw materials (PP resin + anti-static/flame retardant masterbatches) to the extruder, which uses a special exhaust screw and PLC temperature control to fully plasticize materials for high-output extrusion.

Molten material is then injected into a high-precision alloy steel mould to form the hollow grid structure, followed by vacuum shape forming (with low-temperature aluminum cooling plates) for precise shaping. A 5-roller haul-off unit pulls the board at adjustable speed to maintain thickness consistency, while heating-air cooling straightening eliminates internal stress—ensuring flatness and structural stability. After static elimination (to avoid dust adsorption), a 2-roller haul-off provides stable traction before the high-precision cross cutter performs fixed-length cutting. The final process includes bracket placement, quality inspection and moisture-proof packaging, with an optional edge trim recycling system to minimize material waste.

Feature

- Automated intelligent control: Equipped with PLC and touchscreen HMI, realizing closed-loop control of extrusion pressure and speed, with fault auto-diagnosis and remote monitoring—improving production efficiency significantly.

- Precise forming system: Adopts high-quality mould steel and dual vacuum cooling systems, solving wide-width production deformation and ensuring uniform wall thickness and smooth surfaces of PP hollow boards.

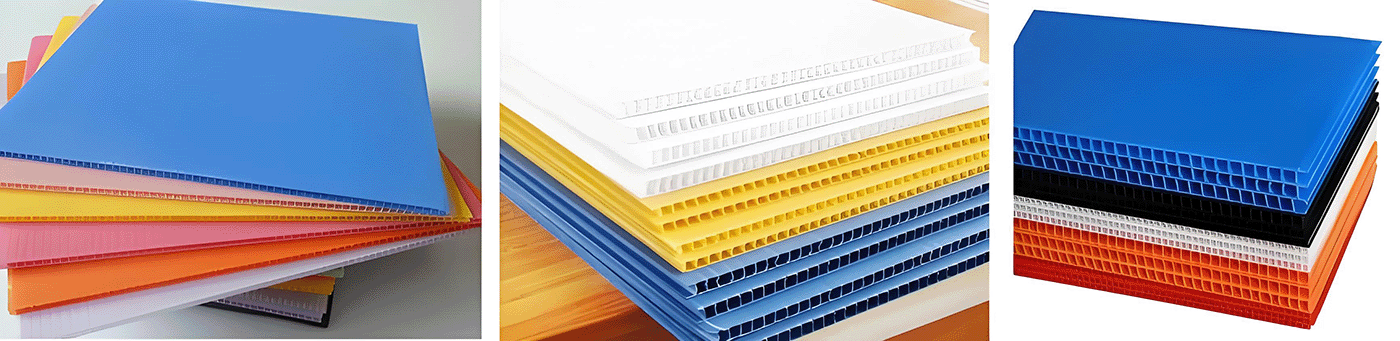

- Flexible customization: Supports adjusting board thickness, width and color; can add anti-static or flame-retardant layers via masterbatches to meet diverse industry safety and performance needs.

- High efficiency & energy saving: Uses energy-saving servo motors to reduce power consumption; optional edge trim recycling system boosts material utilization, suitable for large-volume continuous production.

- Stable product performance: Heating-air cooling straightening eliminates internal stress, making PP hollow boards resistant to warping, impact and corrosion—service life far longer than traditional corrugated cardboard.

- Extended processing compatibility: Optional corona treater enhances surface adhesion, enabling subsequent processes like printing, film lamination and bending—expanding application scenarios.

Technical Parameters

| Description | Technical parameters |

| Material application | PP granules |

| Board spec. | 1200×2-6mm |

| Line speed | 1-8m/min |

| Max. capacity | 260KG/h |

| Outline size | 26000×2200×2500 L×W×H |

| Weight (approx.) | 18 tons |

| Total installed power | 120KW |

| Actual power consumption | 85KW |

| Air consumption | 0.43/min |

| Water pressure | 0.5-0.6MPA |

| water cycling | 0.3/min |

| Power supply | AC440V±10%60HZ |

| Water supply | Industry water, without impurity, under filter treatment, water pressure: 4bar, water temp.15-25℃ |

| Working environment | 0-40℃ |