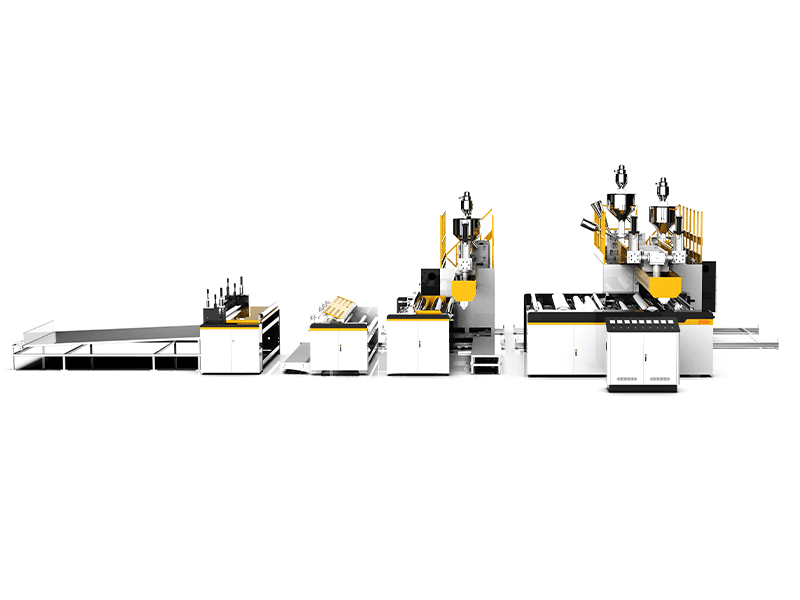

Description

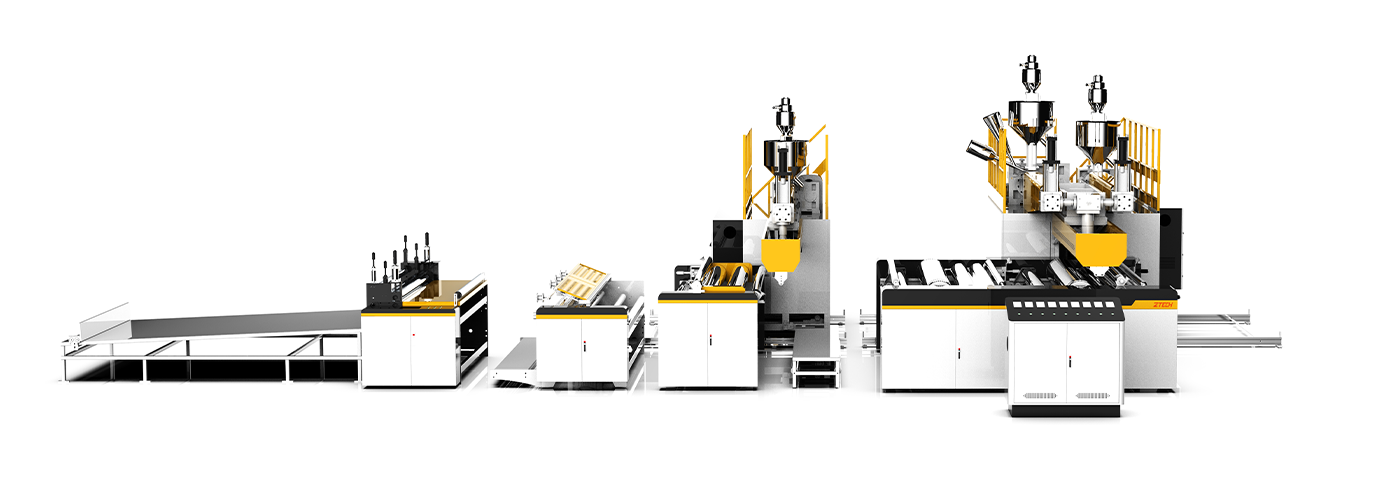

As a dedicated PP film making machine, it focuses on flat sheet production—optimized for scenarios requiring smooth, uniform, and structurally stable plastic sheets. Its extrusion system features a precision-calibrated T-die and a multi-stage calibration roller group, ensuring the produced PP/PE sheets have consistent thickness (ranging from 0.5mm to 10mm) and a smooth surface, with no defects affecting structural performance.

The machine supports flexible material switching between PP and PE, adapting to different hardness and durability requirements. Its integrated high-precision slicer operates in sync with the extrusion line, allowing customization of sheet dimensions: length adjustable from 30cm to 6 meters, width from 50cm to 2 meters (max extrusion width), with cutting accuracy within ±1mm. This one-stop extrusion-slicing workflow eliminates the need for secondary processing, reducing material waste and shortening production cycles.

Additionally, the machine’s screw design is optimized for both PP and PE plasticization—ensuring full melting of raw materials to enhance sheet density and rigidity, meeting the structural support needs of applications like linings and dividers.

Feature

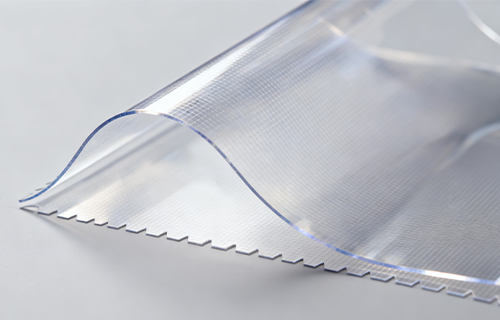

- Flat plastic sheet specialization: Focuses on producing smooth, uniform flat sheets, with a structure optimized for structural support and protective applications.

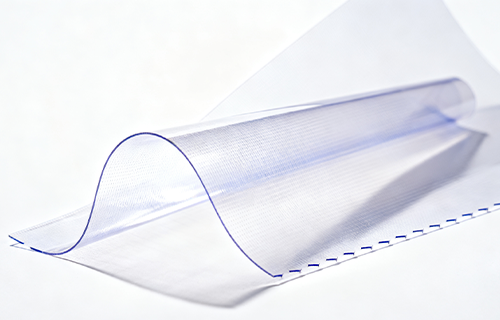

- Dual-material compatibility: Supports single-layer PP or PE material, enabling quick switching to match diverse application requirements for hardness and durability.

- Integrated precision slicer: Customizes sheet length (30cm-6m) and width (50cm-2m) with high accuracy, realizing one-stop extrusion-slicing and saving processing time.

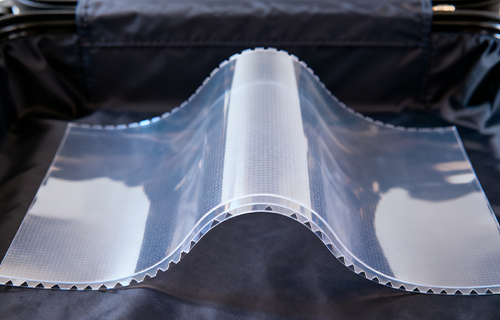

- Adjustable thickness range: Produces sheets with thickness from 0.5mm to 10mm, adapting to light-duty linings (e.g., document sleeves) and heavy-duty structural supports (e.g., luggage liners).

- High structural stability: Optimized extrusion and calibration process ensures sheets have uniform density and rigidity, resisting deformation under pressure or long-term use.

- Smooth surface finish: Precision T-die and calibration rollers deliver defect-free surfaces, suitable for applications requiring printability, product contact, or neat compartmentalization.