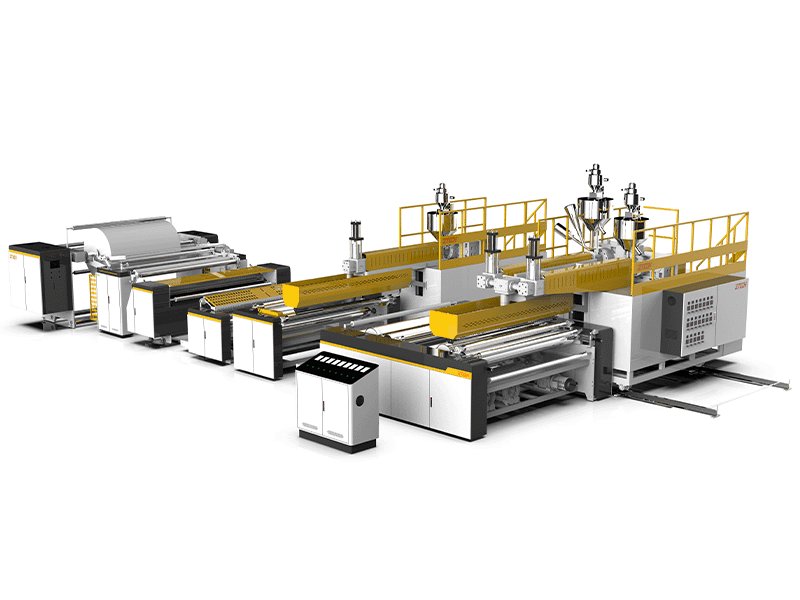

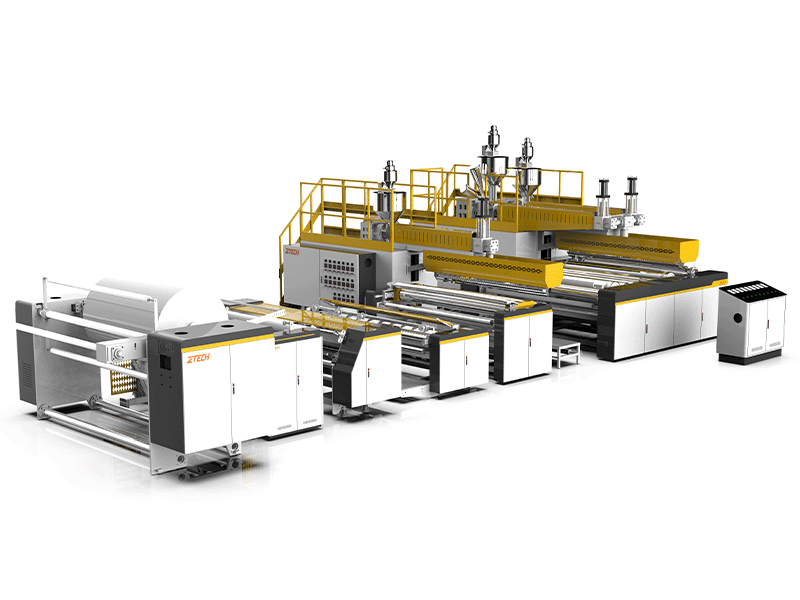

Description

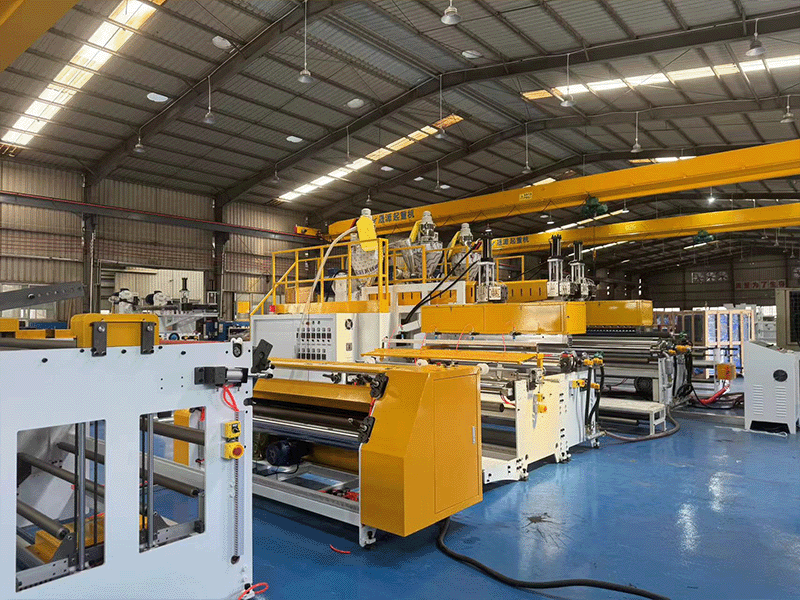

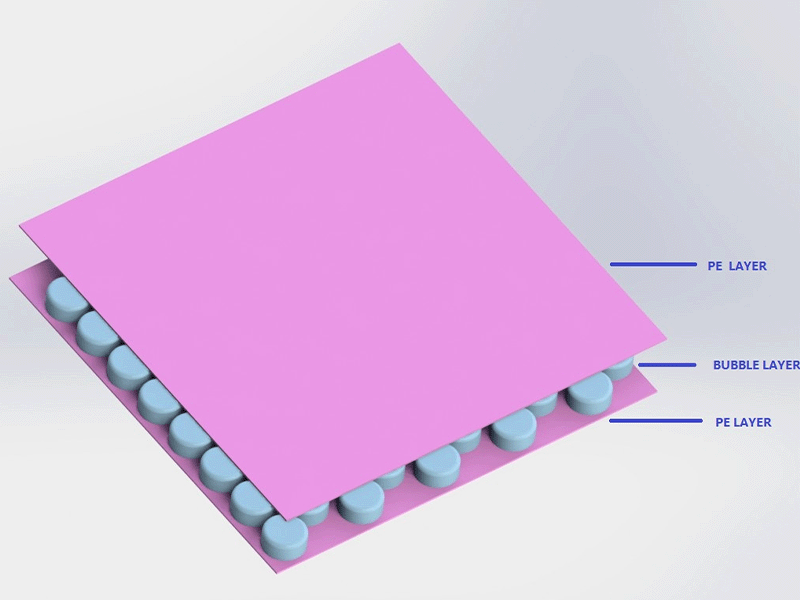

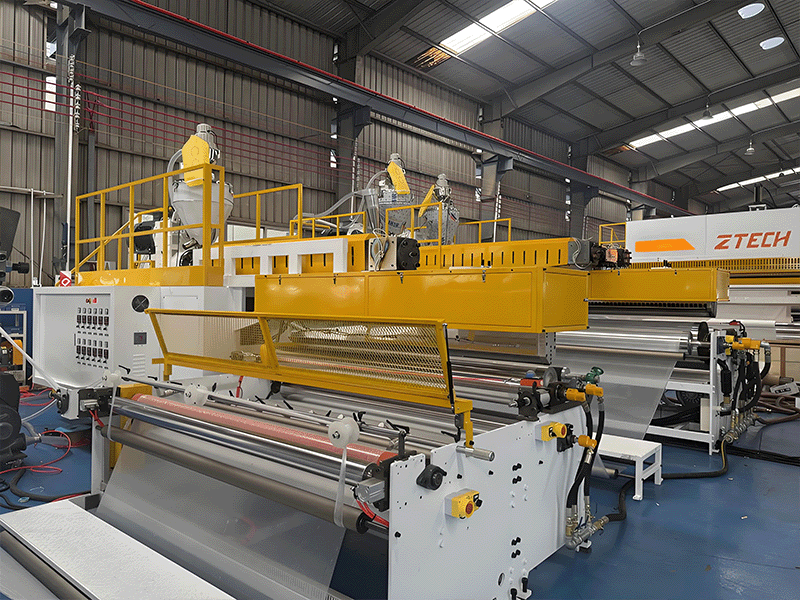

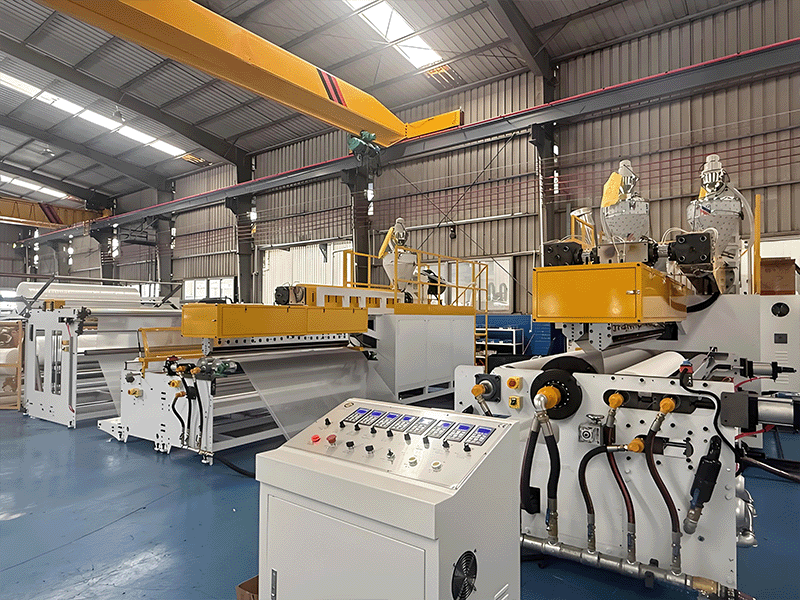

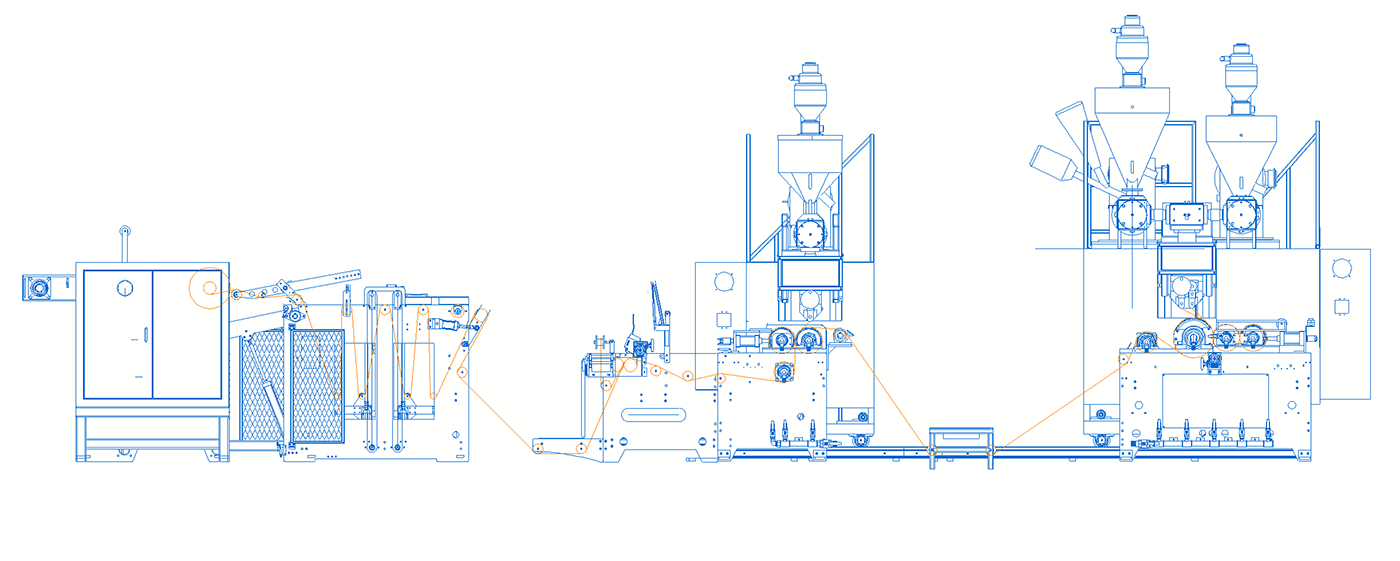

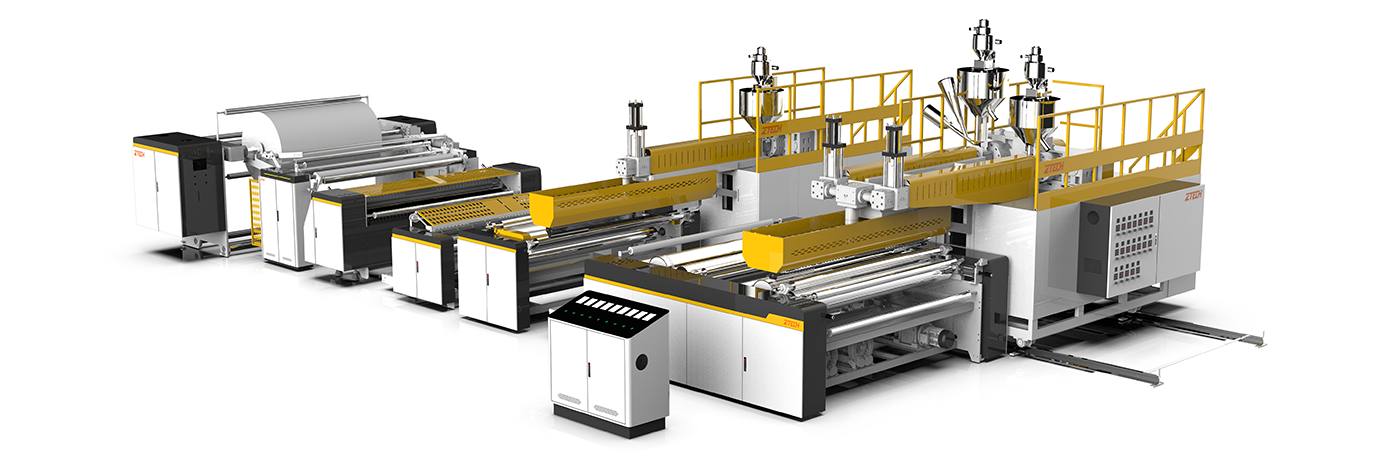

As a multi-functional air bubble film machine, this model stands out with its switchable 2-layer/3-layer production design, adapting to both basic and high-demand packaging scenarios. Unlike single-function machines, it uses a dual-twin screw extrusion system (with unique screw thread design) to separately regulate each layer’s thickness, material ratio, and color: the middle bubble layer ensures shock absorption, while the two outer PE layers enhance puncture resistance and surface smoothness.

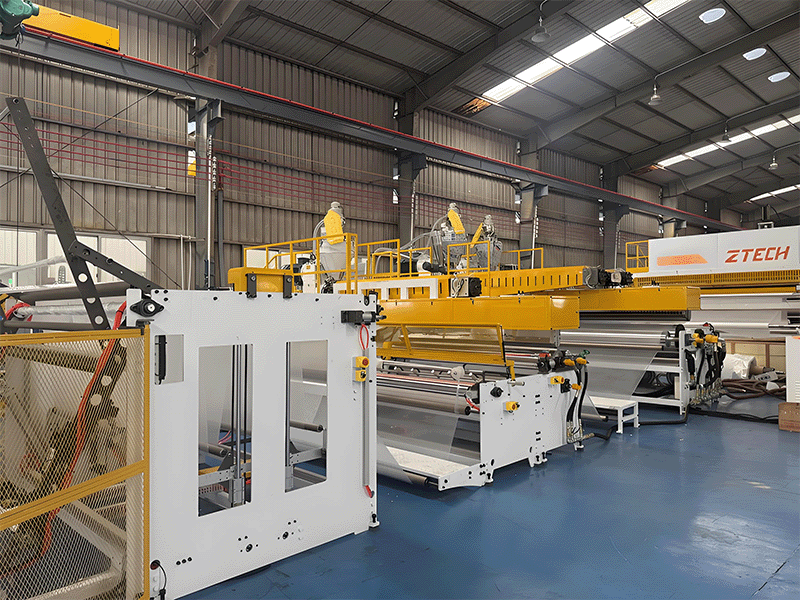

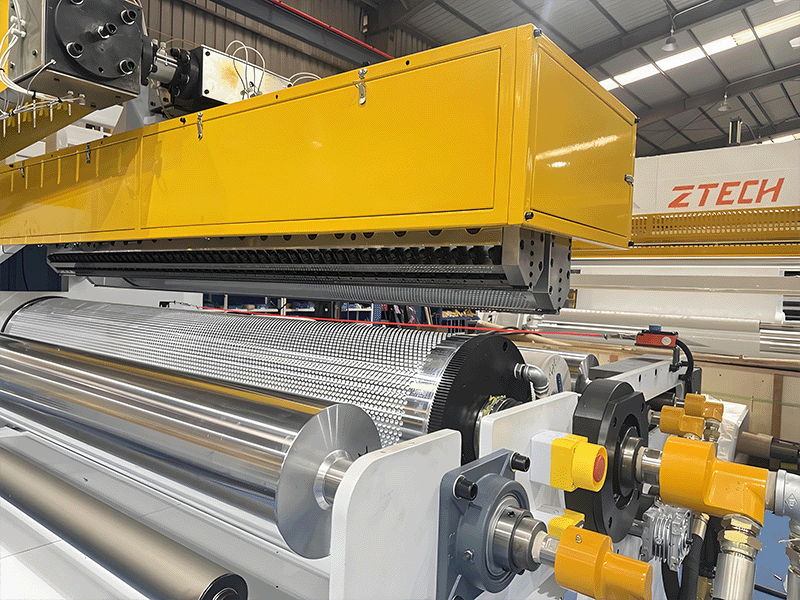

This 3-layer bubble wrap machine supports customized production speeds (standard 40m/min, optional 60m/min) and configurations, such as adding in-line recyclers or automatic winding units. It adopts a high-and-low T-die with rigorous internal structure and reasonable flow channel design, ensuring stable operation even during 24-hour continuous runs. The machine is equipped with a Delta touch screen temperature control system—enabling convenient, precise monitoring of temperature zones, screw speed, and running speed, plus intelligent fault prompts for quick problem-solving.

Feature

- Flexible layer switching: This bubble film machine freely switches between 2-layer and 3-layer production without replacing major parts, saving equipment investment for businesses with diverse needs.

- Independent 3-layer control: Each layer (2 outer PE layers + 1 middle bubble layer) of the air bubble film machine can be adjusted for material, formula, and color separately—enabling high-customization like anti-static outer layers with recycled middle layers.

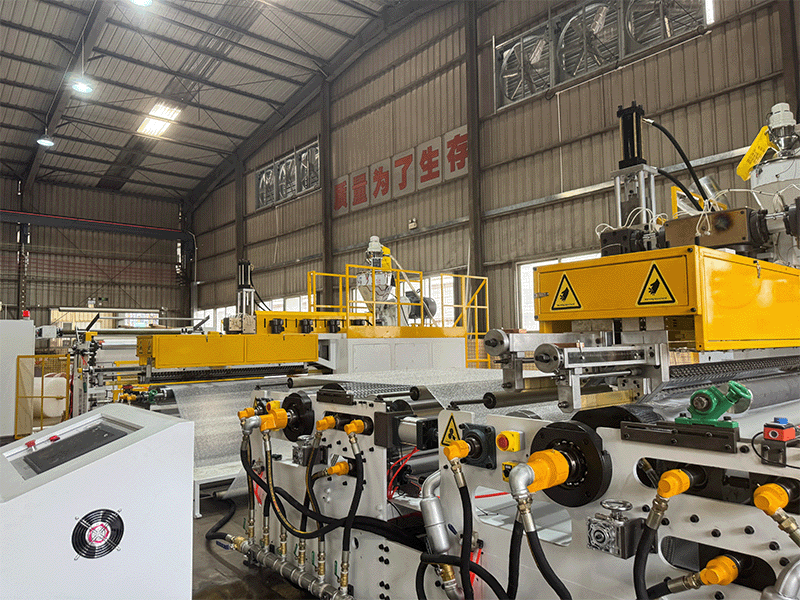

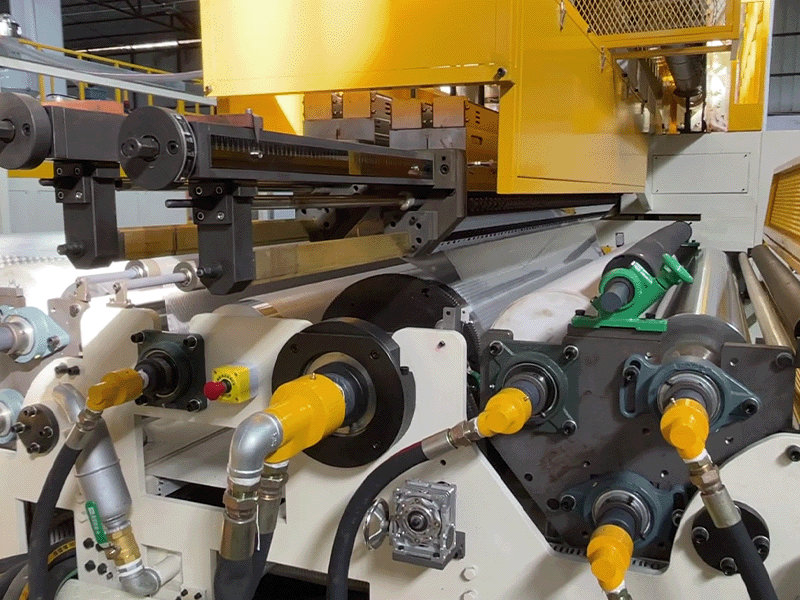

- Premium T-die & screw design: The hanger-type T-die is equipped with unique two-way thickness adjustment screws, ensuring bubble film thickness error within 3g. The exclusive screw design ensures full plasticizing, supporting stable production with common raw materials.

- Intelligent control system: Equipped with Delta touch screen temperature control and advance heating system, saving time and improving efficiency; intelligent fault prompting helps resolve issues quickly.

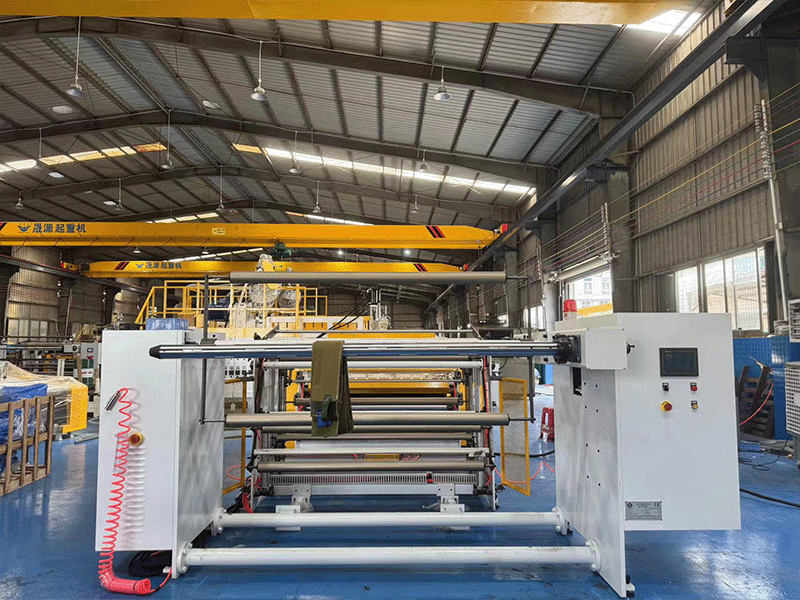

- Customizable speed & safety: Supports speed customization (up to 60m/min for 3-layer film) and has a strict safety system—emergency stop button halts the entire machine instantly, and inductive guardrails stop operations when opened to protect workers.

- Durable bubble roller: Adopts a bubble roller with 3-layer protection (protection plate, copper sheet, vacuum plate) to prevent wear, prolonging service life and reducing maintenance costs.

Technical Parameters

| Model | ZT200-3T Air Bubble Film Twin Screw Extruder |

| Layer | 3 |

| Raw materials | LDPE / LLDPE / PP/ HDPE/ recycled material |

| Maximum width (mm) | 2040 |

| Effective width after trimming (mm) | 2000 |

| Speed (m/hr) | 800m/hr-3000m/hr |

| Production Capacity (kg/hr) | 100kg/hr-300kg/hr |

| Range of film thickness (g/m2) | 2 layers: 25g/sm-500g/sm 3 layers: 45g/sm-800g/sm |

| Main screw diameter (mm) | Φ85mm+Φ75mm |

| Secondary screw diameter (mm) | Φ65mm |

| Power of main motor (kW) | 37KW+22KW |

| Power of secondary motor (kW) | 18.5KW |

| Power of vacuum pump (kW) | 3.0KW |

| Maximum rolling diameter (mm) | Φ1000mm(Can be customized upon requested) |

| Power Supply | 380V,50HZ,3 PHASES(Can be customized according to different countries) |