Description

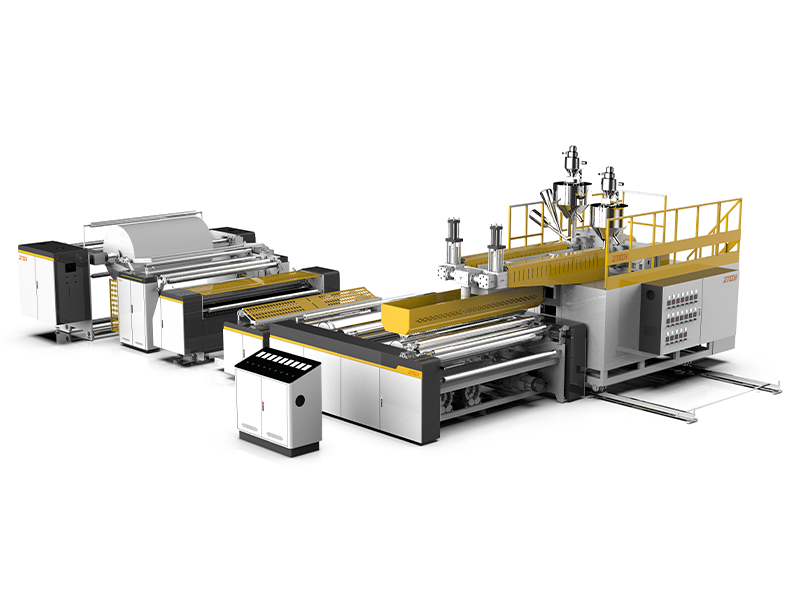

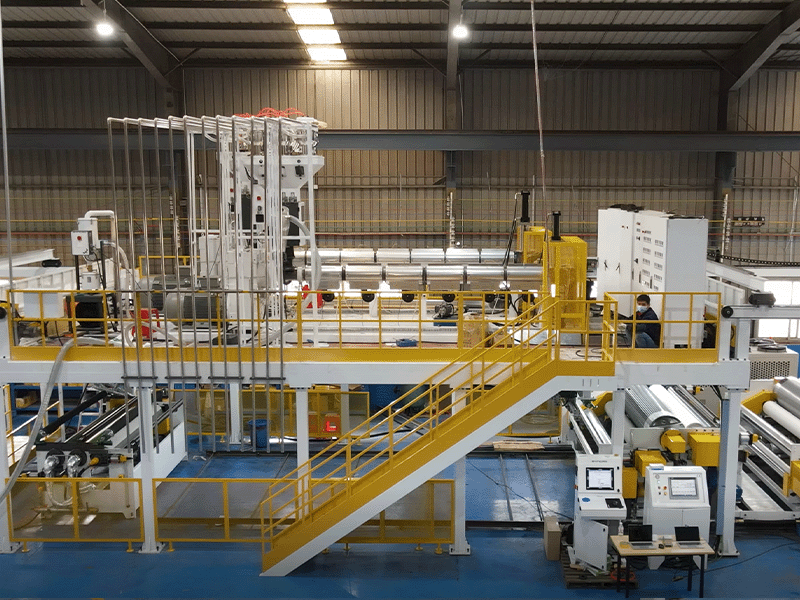

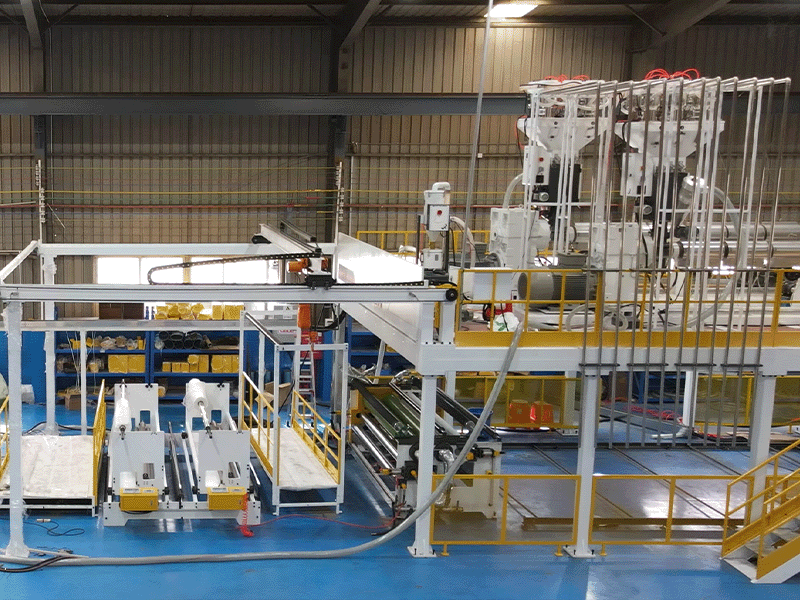

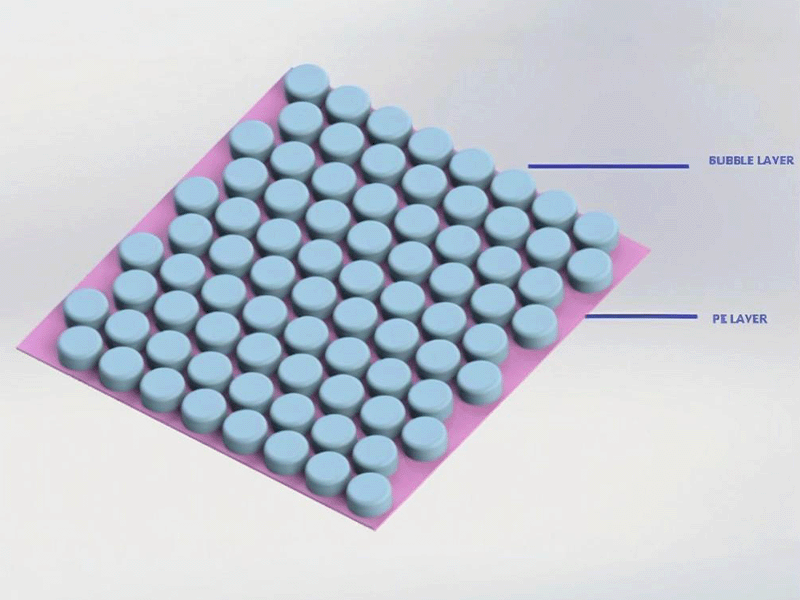

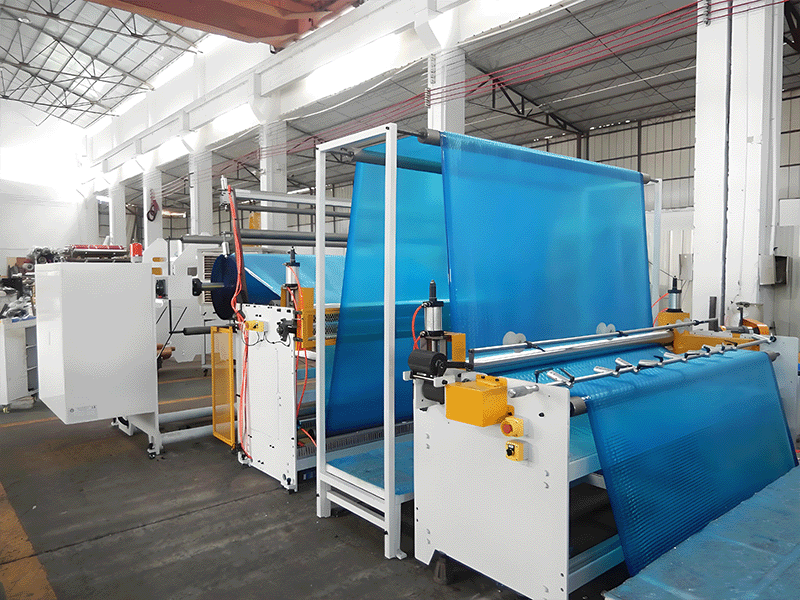

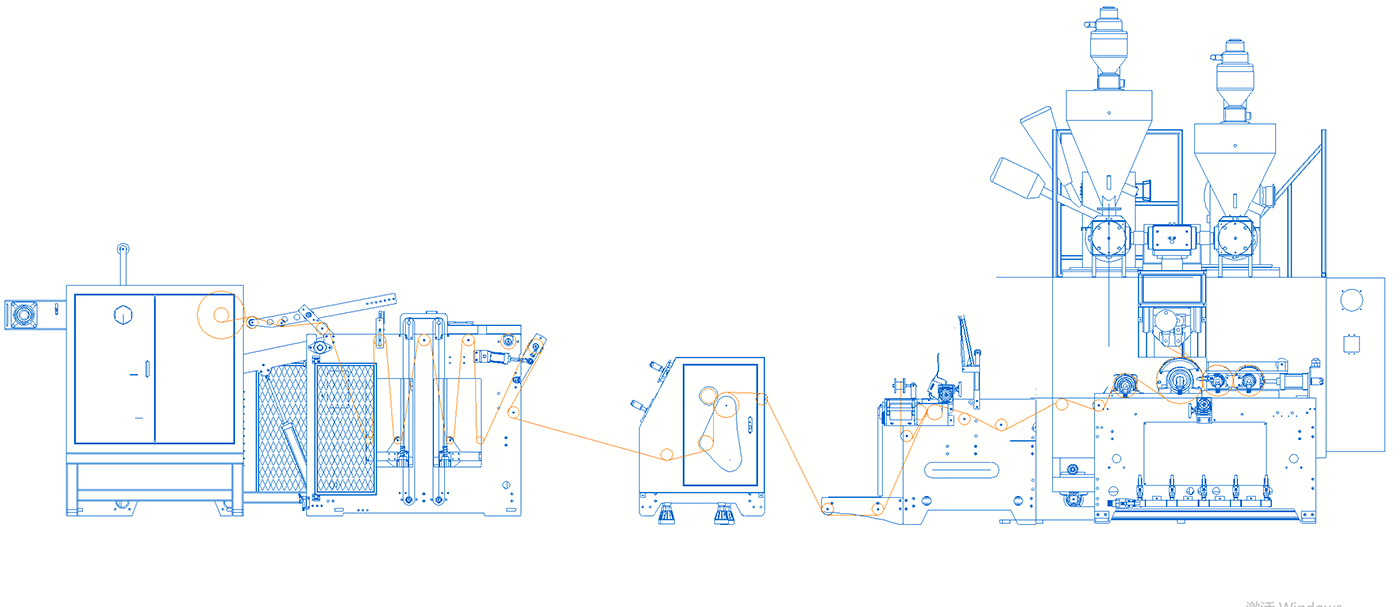

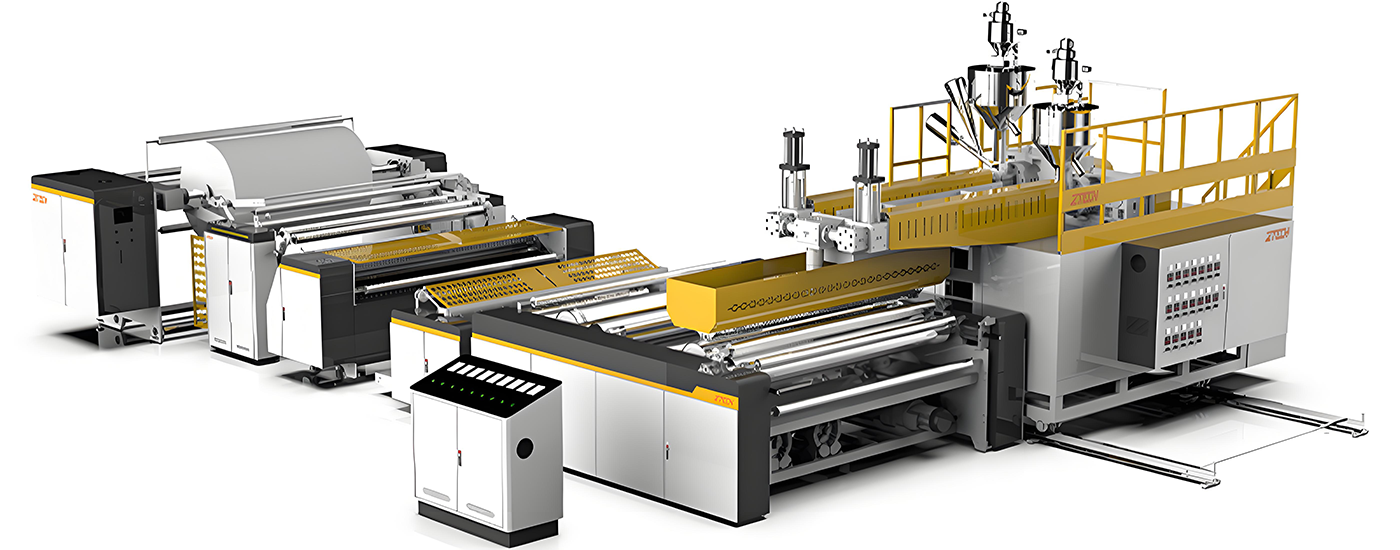

As a professional air bubble film machine, this twin-screw model outperforms single-screw extruders by enabling independent thickness control of the bubble layer and base layer—directly cutting material costs for bubble wrap production. It accommodates diverse raw material formulas to create colored or clear bubble films, ensuring stable operation of the bubble film machine even during long production runs.

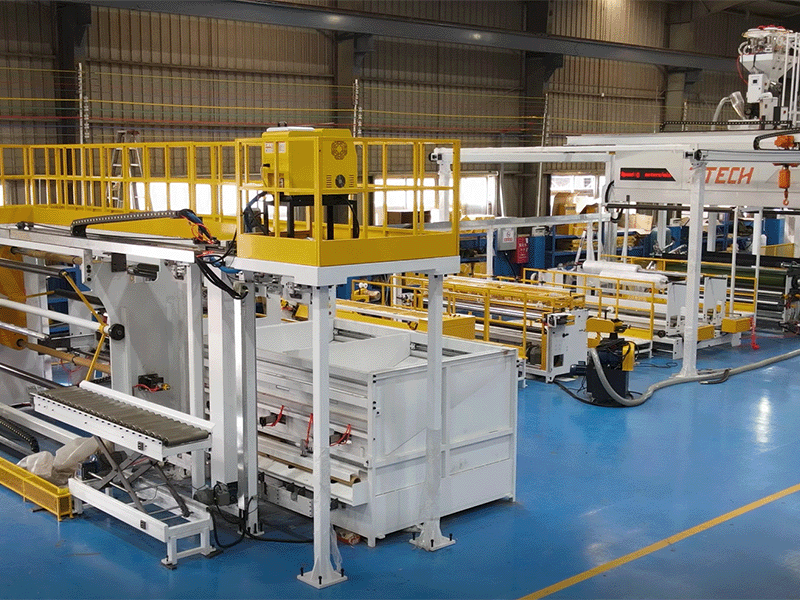

To enhance functionality, this 2-layer bubble wrap machine offers optional peripherals: in-line recycler units for material reuse, bubble film perforators for breathability, and hydraulic screen changers for uninterrupted extrusion. These add-ons make the air bubble film machine adaptable to various production needs, from small-batch customization to large-scale manufacturing.

Feature

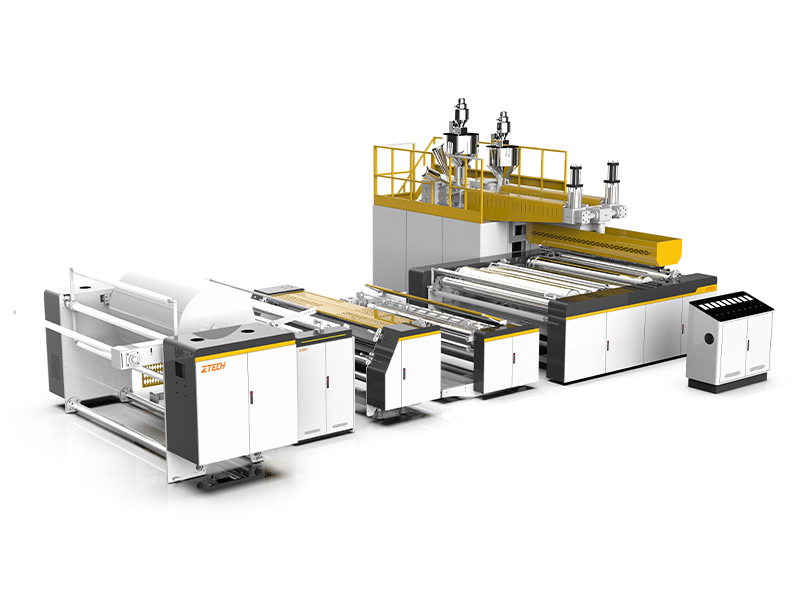

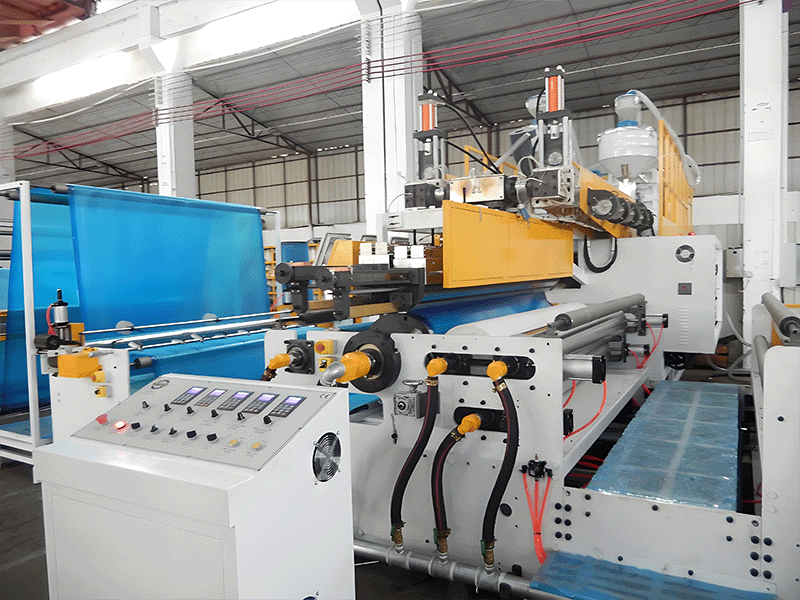

- Compared to single-screw extruders, this bubble film machine allows independent control of bubble layer and base layer thickness, minimizing material waste and reducing production costs significantly.

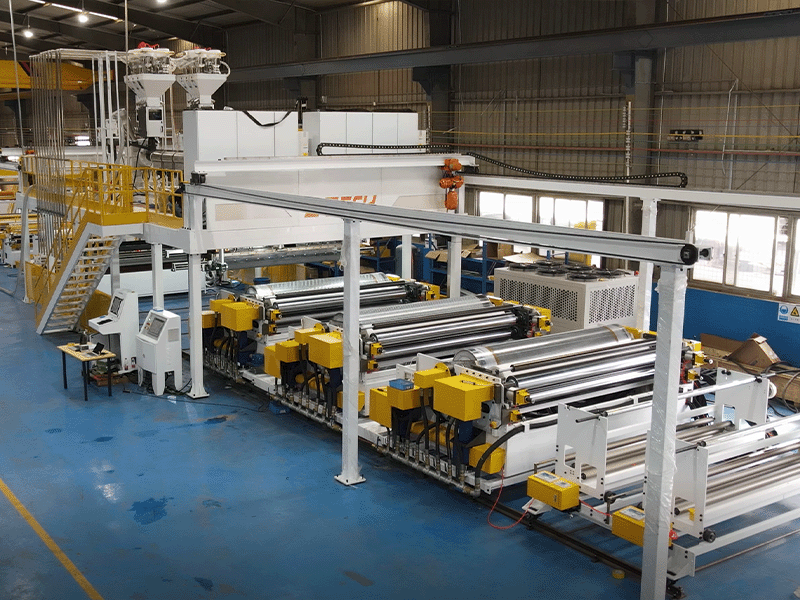

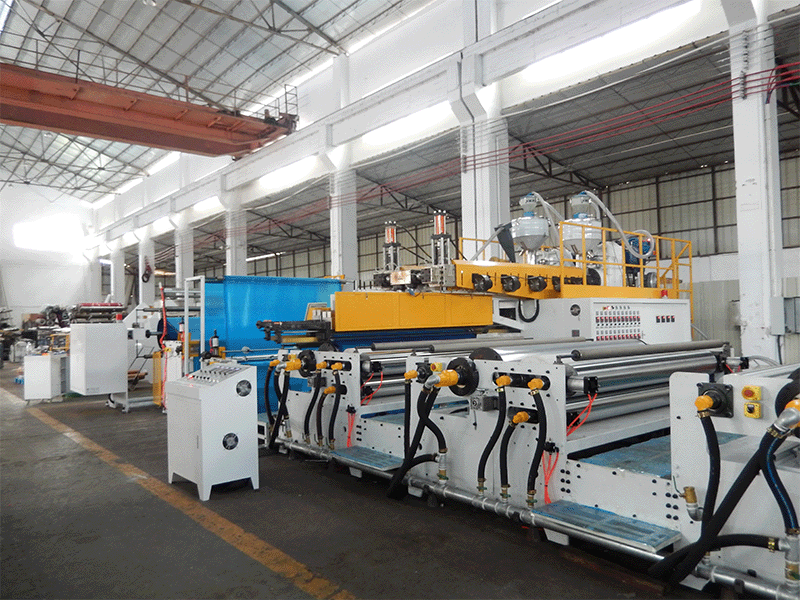

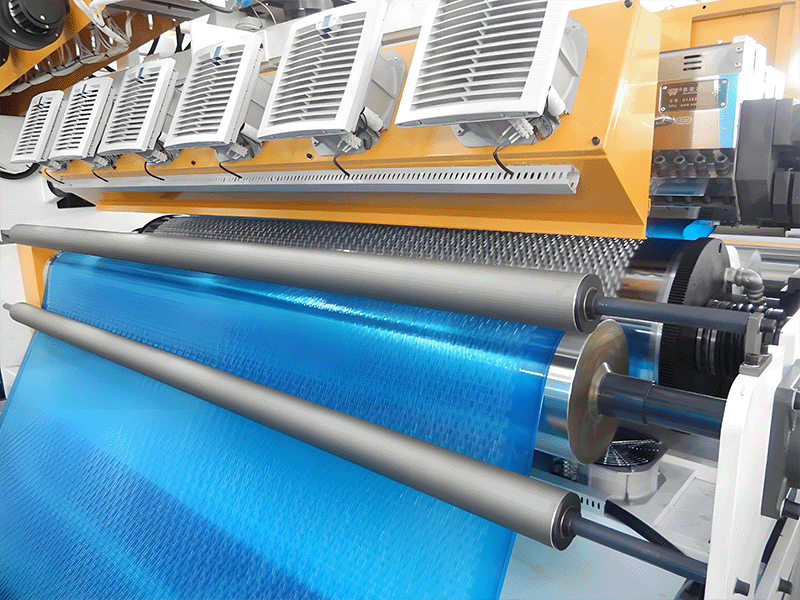

- The forming cylinder mold of the air bubble film machine integrates a vacuum system, wear-resistant special steel sheets, and a dual-pipe cooling system—ensuring uniform cooling and high-quality bubble formation.

- The machine’s T-die uses precision-machined materials, guaranteeing even bubble film thickness, easy operation, and zero glue leakage during the air bubble film production process.

- Unique screw design supports 100% recycled material processing, ensuring full plastic melting. This not only boosts sustainability but also creates bubble films with consistent thickness for the bubble wrap machine.

- High production efficiency: This air bubble film machine achieves a maximum speed of 80 meters per minute, meeting large-volume production demands and shortening delivery cycles for customers.

- Strict safety system protects operators: an emergency stop button halts the entire air bubble film machine (circuits, extruder, roller cylinder) instantly; protective barriers on key parts stop all operations when opened.

Technical Parameters

| Model | ZT150-2T Air Bubble Film Extruder Twin Screw |

| Layer | 2 |

| Raw Material | LDPE / LLDPE / PP/ HDPE/ recycled material |

| Maximum width (mm) | 1540 |

| Effective width after trimming (mm) | 1500 |

| Speed (meters per hour) | 800m/hr-3000m/hr |

| Production capacity (kg/hr) | 80kg/hr-200kg/hr |

| Range of film thickness (g/m2) | 2 layers: 25g/sm-500g/sm |

| Screw diameter (mm) | Φ75mm/Φ65mm |

| Power of main motor | 22KW+18.5KW |

| Power of vacuum pump | 2.2KW |

| Maximum rewinding diameter | 1000mm (Can be customized upon requested) |

| Power supply(volt) | 380V,50HZ,3 PHASES (Can be customized for different countries) |