Description

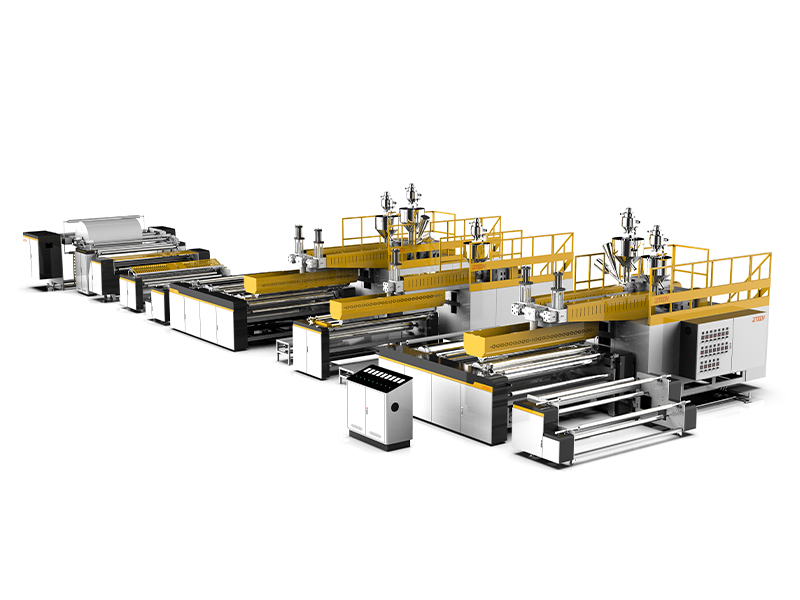

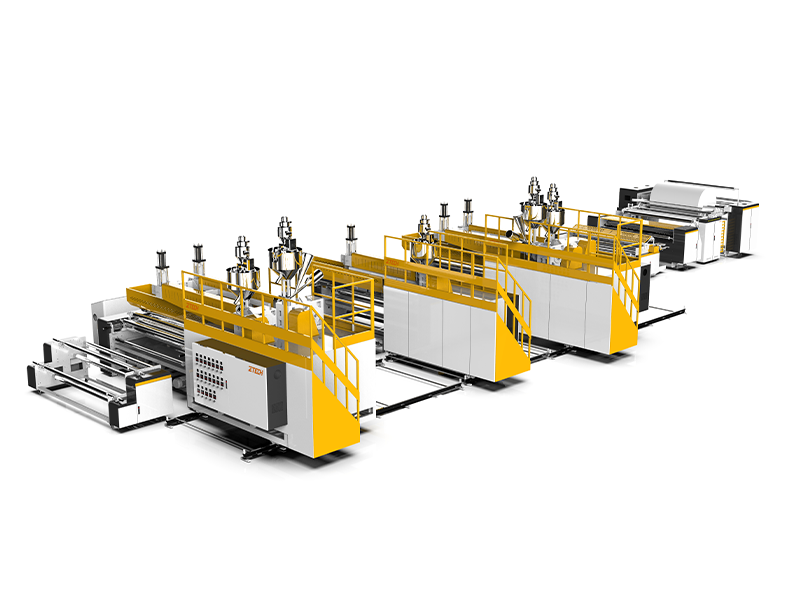

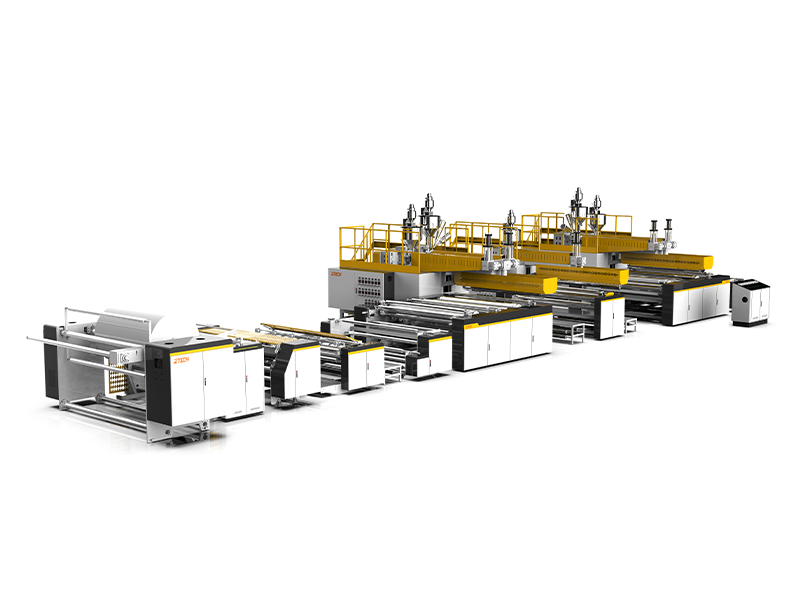

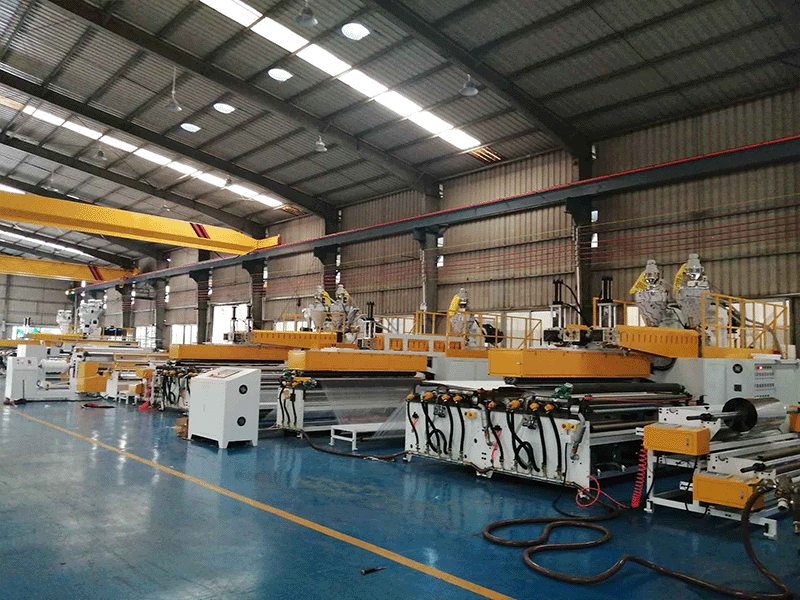

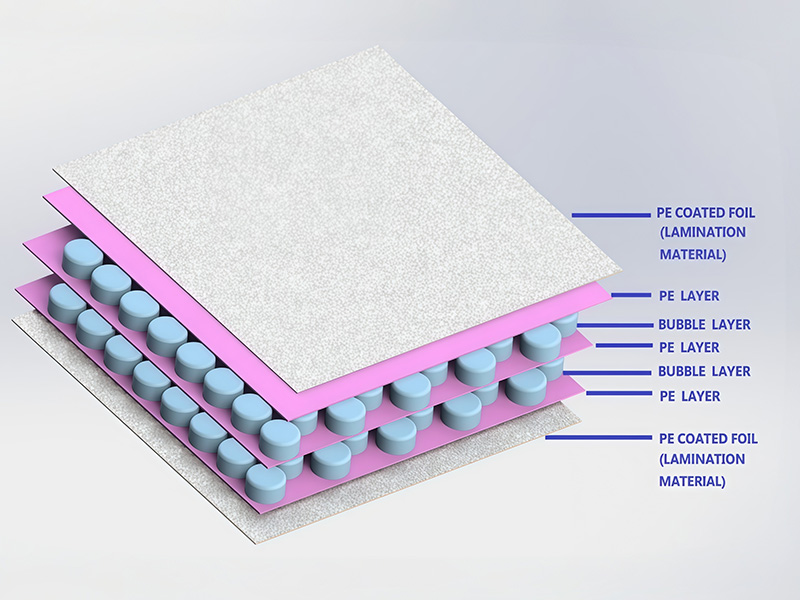

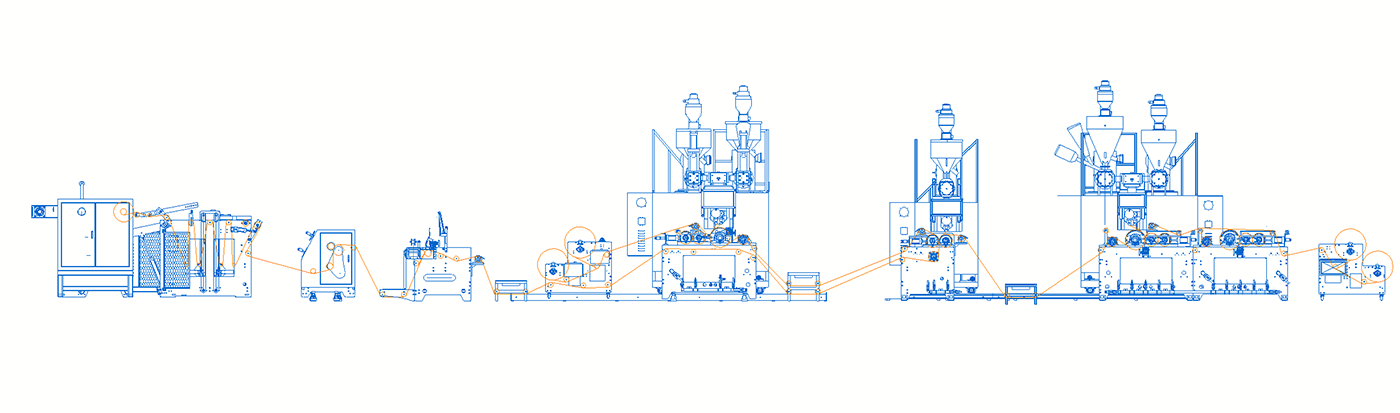

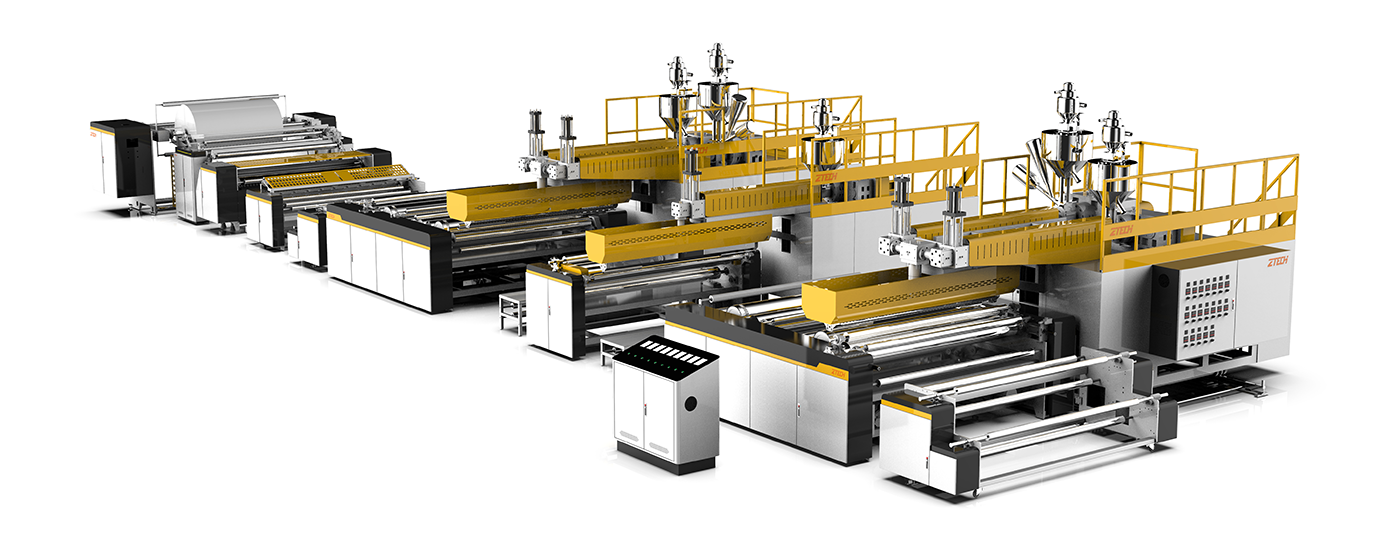

As a high-end 7-layer air bubble film machine, it stands out for its multi-layer switching flexibility and professional composite performance—designed to meet high-demand scenarios like architectural insulation and high-end product packaging. Unlike mid-layer models, this bubble wrap machine adopts a multi-module extrusion & lamination system, which can independently control the thickness, material ratio and functional additives of all 7 layers (including base PE layers, bubble layers, composite material layers and functional auxiliary layers).

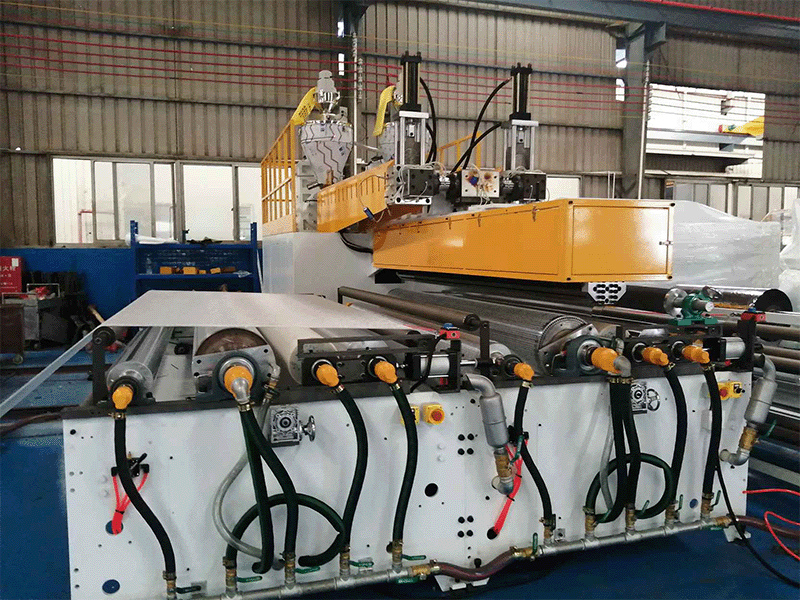

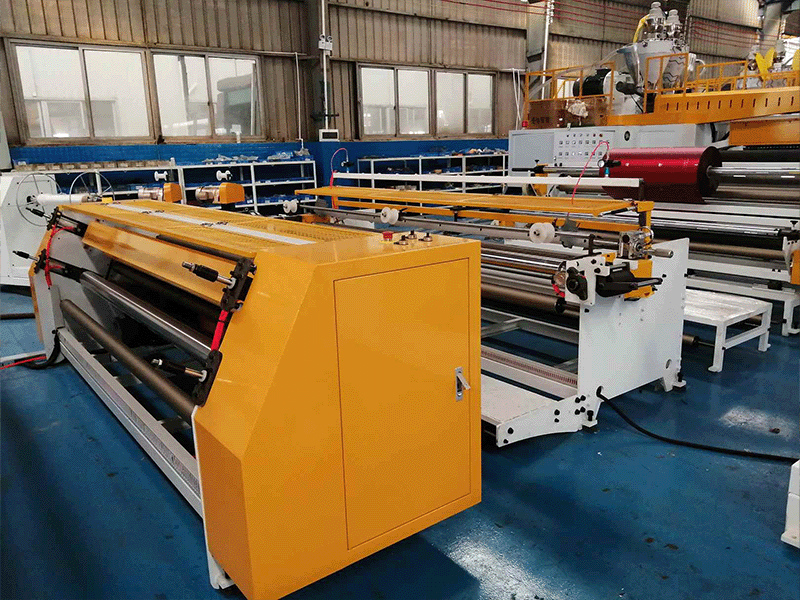

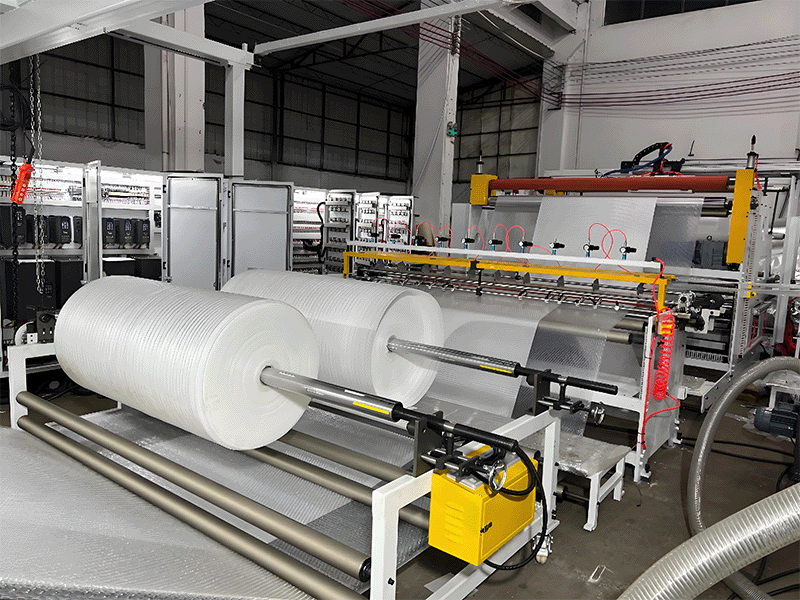

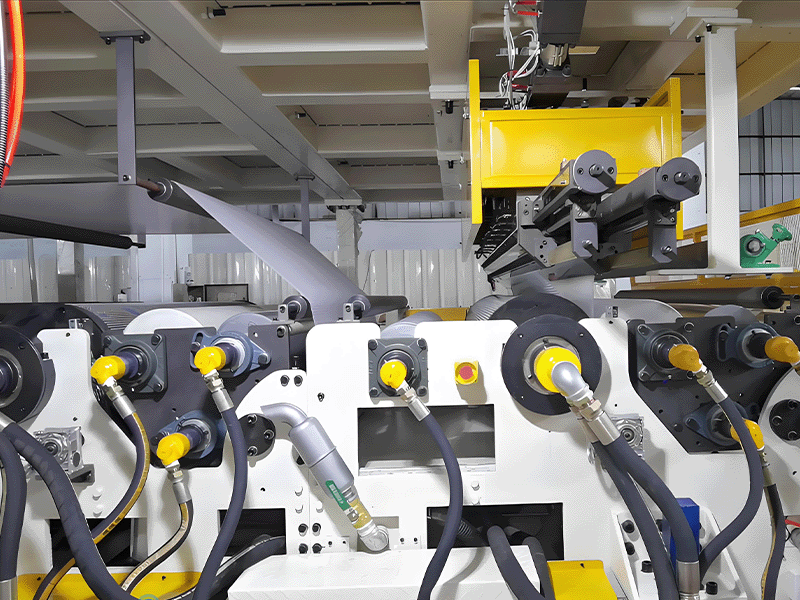

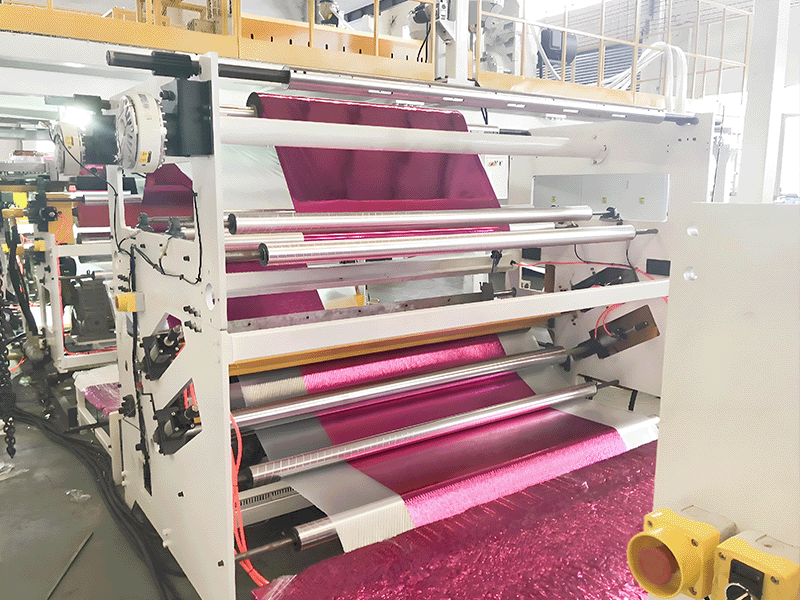

It supports customized high-performance composite structures, with the most mainstream being "PE Layer + Bubble Layer + PE Layer + Aluminum Foil + PE Layer + Bubble Layer + PE Layer"—optimizing thermal insulation for architectural use. The machine is equipped with a high-precision flame retardant additive mixing system, which can evenly blend flame retardants into specified layers (e.g., outer PE layers) to meet common fire safety standards for targeted scenarios. Additionally, its enhanced lamination roller group (with adjustable pressure) ensures firm bonding between thick multi-layer structures and composite materials (especially Aluminum Foil), avoiding delamination even in long-term outdoor use. Optional configurations like automatic thickness detection and edge trimming units further improve production precision for high-end applications.

Feature

- Multi-layer flexible switching: This bubble film machine freely switches between 2-layer/3-layer/5-layer/7-layer production, with 7-layer mode supporting lamination of Aluminum Foil, Kraft Paper and other PE-coated materials—adapting to both common and high-end scenarios.

- Architectural-grade thermal insulation: Optimized 7-layer composite structure (with double bubble layers + Aluminum Foil) significantly enhances heat insulation performance compared to 5-layer film, meeting basic architectural roof/ wall insulation requirements.

- Built-in flame retardant system: Equipped with a precision additive mixing unit, which can evenly add flame retardants to specified layers; the produced 7-layer bubble film has reliable flame retardant properties, reducing fire risks in applicable scenarios.

- High-strength lamination: Enhanced lamination rollers with adjustable pressure ensure firm bonding between Aluminum Foil and multi-layer bubble film, resisting peeling in outdoor/ high-temperature environments for long-term use.

- Precision control for high-end use: Adopts touch screen + PLC control system, real-time monitoring of each layer’s thickness, temperature and tension; thickness consistency meets high-end product packaging requirements.

- Durable outdoor adaptation: Key components (like lamination rollers, forming cylinders) use anti-oxidation and anti-UV materials, ensuring the air bubble film machine runs stably even when producing outdoor-use composite films.

Technical Parameters

| Model | ZT250-7T Air Bubble Film Twin Screw Extruder |

| Layers | 7 |

| Raw Material | LDPE / LLDPE / PP/ HDPE/ recycled material |

| Maximum width (mm) | 2540 |

| Effective width (after edge timming, mm) | 2500 |

| Speed (meters per hour) | 800m/hr-3000m/hr |

| Production Capacity (kg/hr) | 200kg/hr-700kg/hr |

| Range of film thickness (g/m2) | 2 layers: 25g/sm-500g/sm 3 layers: 45g/sm-800g/sm 5 layers: 80g/sm-1200g/sm |

| Front Screw diameter (mm) | Φ100mm+Φ80mm |

| Secondary screw diameter (mm) | Φ80mm |

| Back main screw diameter (mm) | Φ100mm+Φ80mm |

| Power of front main motor(kW) | 55KW+30KW |

| Power of secondary motor(kW) | 30KW |

| Power of back main motor(kW) | 55KW+30KW |

| Power of vacuum pump | 3.0KW |

| Unwinder rack | 2 sets with maximum diameter of Φ500mm |

| Lamination materials | aluminum foil, film laminating kraft paper, EPE foam, PE film, etc. |

| Maximum winding diameter | Φ1000mm (Can be customized upon requested) |

| Power supply(volt) | 380V,50HZ,3 PHASES (Can be customized for different countries) |