In modern logistics and packaging industries, product transport safety and packaging quality have become central concerns for both enterprises and customers. Fragile items such as electronics, precision instruments, and glass products are particularly susceptible to damage if packaging protection is insufficient, leading directly to increased losses and costs. To address this issue, the air bubble film machine serves as key production equipment, manufacturing high-performance bubble films with precision, multi-layer structures, and advanced technologies, providing reliable packaging protection.

This article will analyze the working principles, key technologies, and applications of air bubble film machines, with a focus on how multi-layer structures, co-extrusion technology, and high-speed automated production enhance packaging protection.

How Air Bubble Film Works to Protect Products

Bubble film is one of the most widely used cushioning materials in packaging, primarily designed to absorb external impacts and safeguard fragile products. The bubble film making machine produces bubble film by forming independent air-filled cells, where each bubble acts as a miniature cushioning unit. When external force is applied, these bubbles distribute the impact evenly, preventing direct stress on the product surface and reducing the risk of breakage.

The protective performance of bubble film depends on several key factors:

• Bubble size and arrangement: Smaller bubbles are ideal for cushioning delicate items, while larger bubbles provide shock absorption for bulkier products.

• Film thickness: Uniform thickness ensures consistent cushioning performance.

• Material strength: The choice of PE, PP, HDPE, or Nylon determines the film’s toughness and wear resistance.

The bubble films produced by the high-quality air bubble film machine can not only ensure uniform size and thickness, but also adjust the material formula and bubble structure according to product requirements, thereby maximizing the packaging protection effect. Especially in long-distance transportation and cross-border logistics, high-performance bubble films are particularly important.

Why Air Bubble Film Machine Quality Directly Affects Protection Performance

In practice, packaging companies often find that even with the same raw materials, bubble films produced on different machines vary significantly in protective performance. These differences typically stem from the air bubble film machine’s performance in key production stages.

• Thickness control: High-quality bubble film extrusion machines enable precise adjustment of bubble and base layer thickness, ensuring protection while minimizing material waste. Inconsistent thickness can compromise bubble strength and increase packaging costs.

• Forming stability: The design of forming rollers, cooling systems, and vacuum stabilization significantly affects bubble fullness and uniformity. Poorly designed or low-quality machines may produce collapsed or uneven bubbles during high-speed or long-duration operation, weakening packaging protection.

• Temperature control and die precision: A stable bubble film making machine ensures uniform melt flow and avoids weak spots caused by temperature fluctuations, which is crucial for maintaining bubble film reliability during transportation.

How Multi-Layer Bubble Film Machine Enhances Packaging Protection

Multi-layer bubble film machines enhance protective performance through flexible layer configurations and independent control of each layer. Different machine types are suitable for various protection requirements:

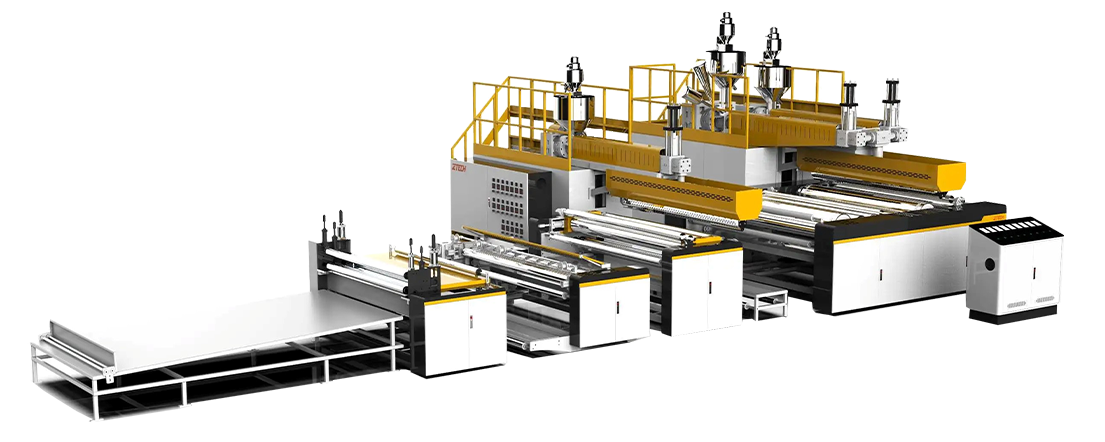

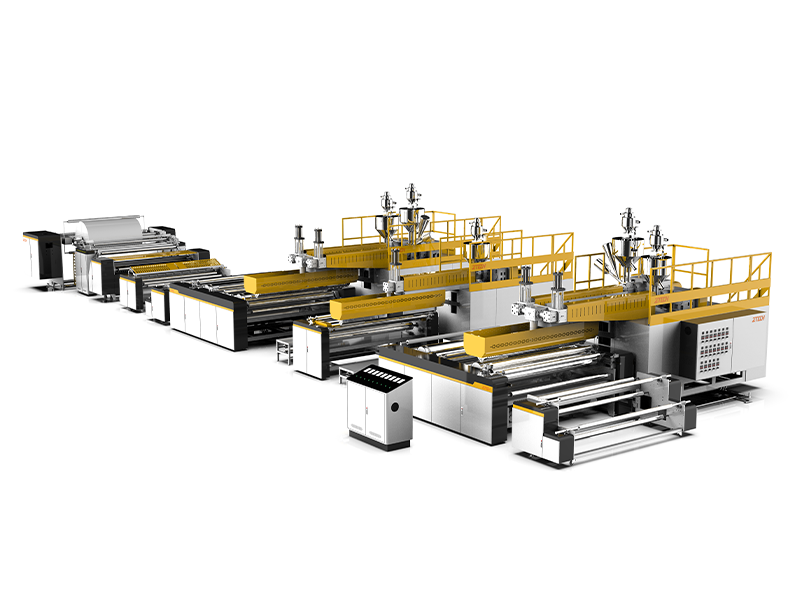

1. 2-Layer Air Bubble Film Machine

The 2-layer machine is ideal for standard packaging cushioning. The bubble layer absorbs external shocks, while the PE base layer provides film toughness and tear resistance. Air bubble film machines with independent control of bubble and base layer thickness optimize material usage, ensure uniform cushioning, and reduce the risk of collapsed or weak bubbles. This type is suitable for electronics, ceramics, and other lightweight to medium fragile products, providing stable protection while maintaining high production efficiency for daily logistics.

2-layer air bubble film machine

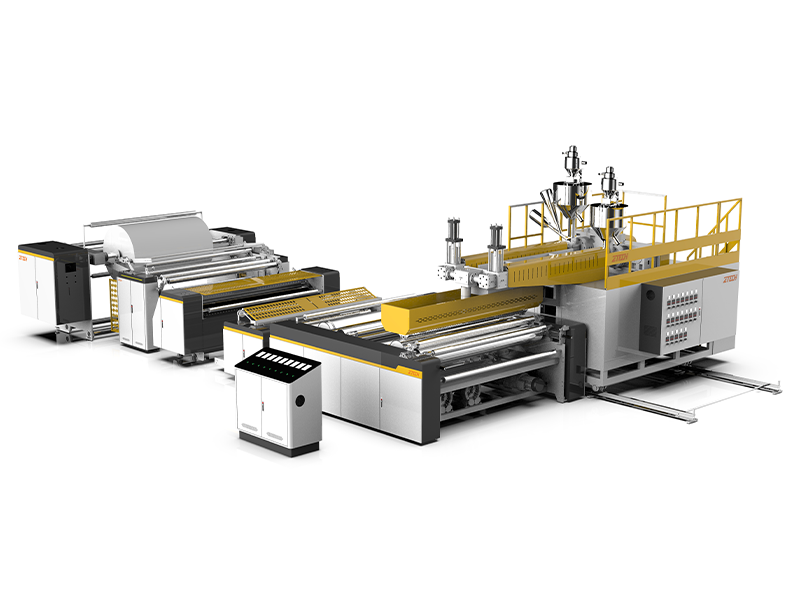

2. 3-Layer Air Bubble Film Machine

The 3-layer machine adds puncture resistance and surface smoothness on top of cushioning performance. The central bubble layer absorbs impacts, and the outer PE layers enhance puncture resistance and abrasion protection. This configuration is particularly suitable for e-commerce logistics and precision instrument packaging. Bubble film making machines with switchable 2-layer/3-layer production allow independent adjustment of thickness and color for each layer. Paired with automatic winding and inline recycling systems, this setup improves production efficiency while ensuring uniform cushioning performance during transport and stacking.

3-layer air bubble film machine

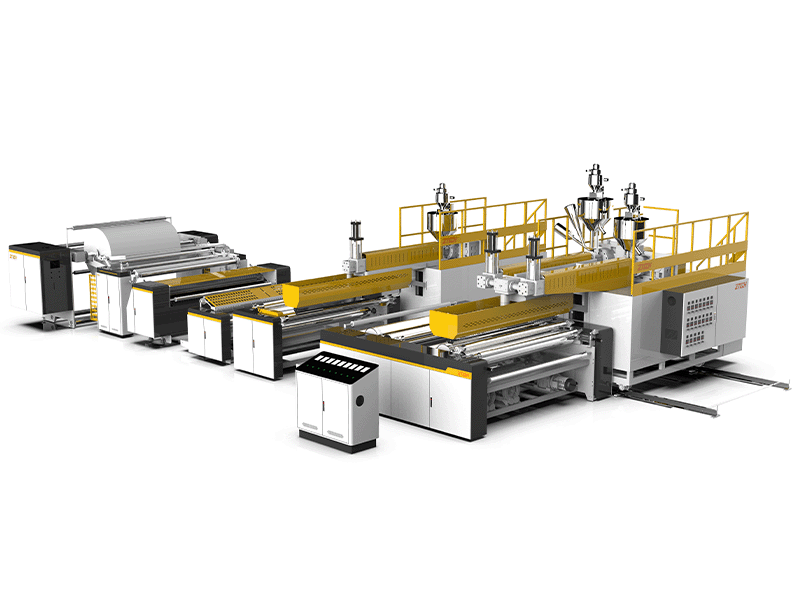

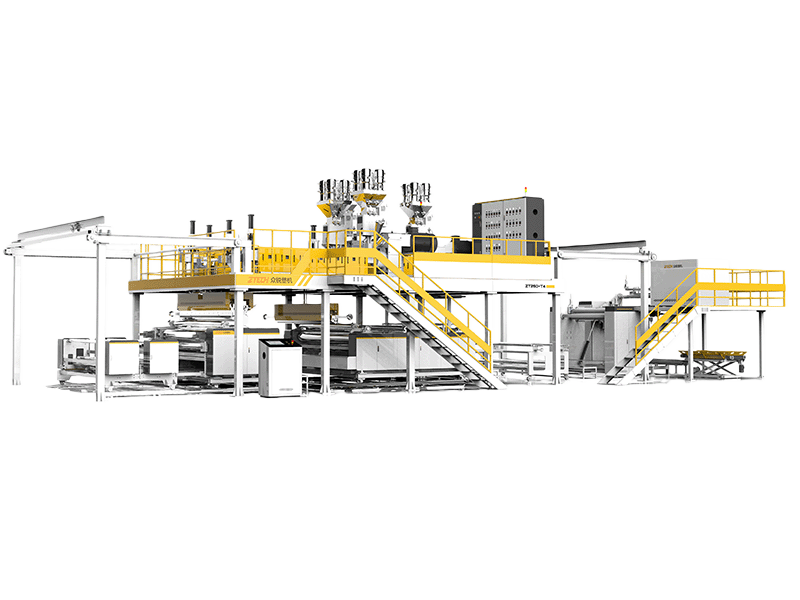

3. 5-Layer Air Bubble Film Machine

The 5-layer machine integrates composite material capabilities, combining bubble film with PE-coated materials such as aluminum foil, kraft paper, EPE foam, or HDPE film. Multi-layer bubble film machines independently control the thickness and proportion of each layer, maintaining bubble layer cushioning while outer layers provide moisture, heat, and flame protection. This type is ideal for high-end products, long-distance transport, and special environmental packaging. Multi-layer composite films reduce secondary processing steps, cut material waste, and lower production costs while enhancing protective performance.

5-layer air bubble film machine

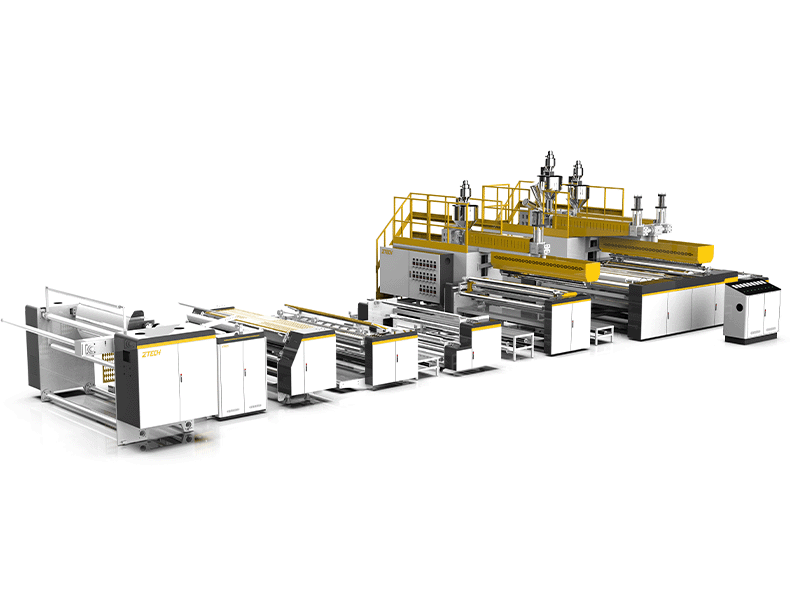

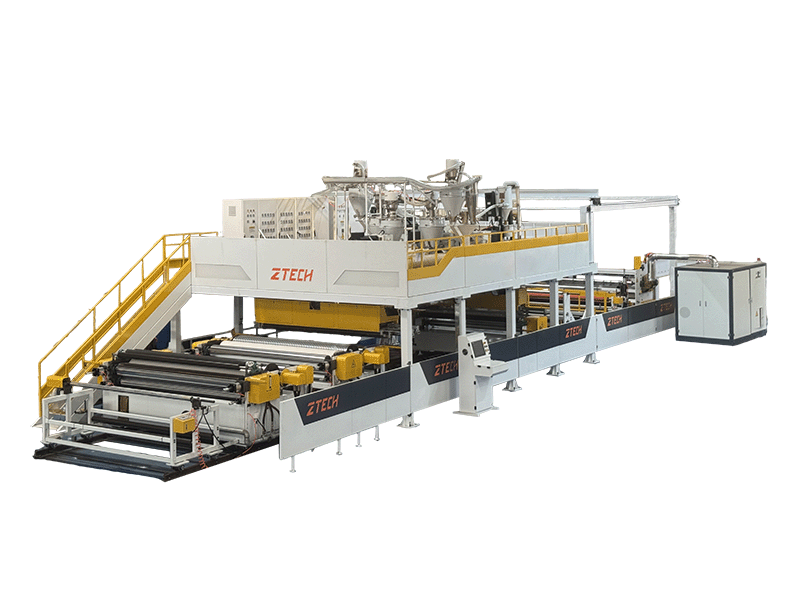

4. 7-Layer Air Bubble Film Machine

The 7-layer machine is designed for high-end or extreme protection requirements, including construction materials, precision instruments, long-distance logistics, and luxury product packaging. Its multi-module extrusion and lamination system allows independent control of thickness, material ratios, and functional additives such as flame retardants or thermal insulation layers. The composite material structure significantly improves impact absorption, heat insulation, and durability, maintaining superior cushioning even under long-distance transport, outdoor exposure, or high-temperature conditions. The 7-layer system also allows flexible adjustment to meet different protection scenarios.

7-layer air bubble film machine

How Co-Extrusion Technology Improves Bubble Film Durability

Co-extrusion bubble film machinery enhances long-term durability and stability. By fusing multiple material layers during the extrusion process, each layer can be independently adjusted in thickness, ratio, and functional additives, ensuring consistent performance during transportation and storage.

1. ABA Co-Extrusion Air Bubble Film Machine

The ABA machine uses a unique three-layer co-extrusion structure: the bubble layer (PE + PP/HDPE + PE) and base layer (PE + PP/HDPE + PE) are composed of three fused layers, improving film hardness and toughness.

• Durability improvement: Multi-layer composition enhances compression and vibration resistance, keeping bubbles stable even under heavy loads.

• Air retention: Co-extrusion reduces gas leakage, extending bubble life and maintaining cushioning performance.

ABA co-extrusion air bubble film machine

2. Nylon Co-Extrusion Air Bubble Film Machine

The Nylon 5-in-1 co-extrusion machine is ideal for high-end products and long-distance transport, with bubble and base layers composed of PE + TIE + NYLON + TIE + PE.

• Superior durability: Nylon layers increase toughness and tear resistance, preventing rupture during long-distance or repeated handling.

• Air retention: Tests show that ordinary 2-layer films lose up to 50% of air in 14 days, whereas nylon co-extruded films lose only 5%, ensuring long-term cushioning.

nylon co-extrusion air bubble film machine

How High-Speed and High-Output Machines Maintain Protection Consistency

As packaging enterprises scale up, high-speed bubble film machines and high output bubble film machines have become essential. Increased speed does not mean compromised protection; equipment design is the key.

• Screw and die design optimization: Multi-segment screws and optimized thread distribution control melt flow and pressure at high speed, ensuring uniform thickness and full bubbles. Precision T-die channels distribute melt evenly, minimizing local thin spots or collapsed bubbles.

• Cooling and vacuum systems: Dual or multi-stage cooling ensures rapid bubble formation, while vacuum systems maintain bubble fullness, reducing collapse risk even at high speeds. Intelligent vacuum monitoring adjusts suction strength automatically.

• Temperature control and automated monitoring: Multi-zone temperature control allows precise melt and forming regulation. Touch-screen systems monitor temperature, screw speed, line speed, and thickness, automatically alerting or adjusting parameters if abnormalities occur.

• Energy-efficient high output: Optimized screw and die design reduce energy consumption, ensuring stable production with lower operating costs.

Choosing the Right Air Bubble Film Machine for Different Protection Needs

Selecting the right air bubble film machine depends on packaging requirements, transport conditions, and product types. Bubble film machine manufacturers offer a variety of multi-layer, co-extrusion, high-speed, and automated models to meet diverse needs:

• Electronics and precision instruments: 3-layer or 5-layer air bubble film machines for uniform cushioning and puncture protection.

• Furniture and household goods: 2-layer machines provide general cushioning at a lower cost.

• High-end logistics and long-distance transport: 7-layer high-end composite machines combine cushioning, moisture resistance, heat insulation, and flame retardancy.

• Construction materials and heavy components: 5-layer composite machines with multi-material lamination enhance compression resistance and durability.

• High-precision or outdoor packaging: Nylon co-extrusion machines ensure long-lasting bubble retention and superior durability.

ZTECH, as a professional manufacturer, provides complete solutions from 2-layer and 3-layer machines to advanced multi-layer composite systems, tailored to various protection requirements.

Conclusion

The air bubble film machine plays an indispensable role in modern packaging. From the protective principle of bubble films, multi-layer design, co-extrusion technology, to high-speed, high-output, and automated production, every aspect directly affects packaging performance. Choosing the right bubble film making machine not only enhances protection but also improves material efficiency, production speed, and cost control.

As a professional bubble film machine manufacturer, ZTECH offers a comprehensive product line and technical expertise, delivering high-performance, efficient bubble film solutions to global enterprises and enabling them to gain a competitive edge in the logistics and packaging industry.

FAQ

Q1: What products are suitable for bubble films produced by bubble film machines?

A1: Bubble films are suitable for electronics, glassware, ceramics, precision instruments, furniture, food, and other fragile or high-value items. Different layers and material configurations can meet varied protection requirements.

Q2: What advantages do multi-layer bubble film machines offer over single-layer machines?

A2: Multi-layer machines allow independent control of each layer’s thickness and material, providing both cushioning and puncture resistance. They can also integrate aluminum foil, kraft paper, or EPE layers to meet high-end packaging needs.

Q3: How does co-extrusion technology impact packaging protection?

A3: Co-extrusion combines different material properties, enhancing film toughness, compressive strength, and air retention, ensuring stable cushioning even during long-distance transport.

Q4: Will high-speed bubble film machines affect product quality?

A4: With precision temperature control and optimized die design, high-speed machines maintain uniform thickness and bubble integrity, preserving protective performance at high production rates.