As the industry evolves, the versatility of the bubble bag making machine has expanded. It is no longer just about making a simple pouch; it is about precision, speed, and material efficiency. From the traditional air bubble bag machine used for standard shipping to the specialized EPE foam bag making machine for sensitive surfaces, the technology behind these systems has become highly sophisticated.

This guide provides a detailed introduction to bubble bag making machines, covering aspects such as working principles, machine types, application scenarios, selection criteria, maintenance methods, and future technological trends.

What is the Air Bubble Bag Machine

In essence, an air bubble bag machine is an industrial system designed to convert cushioning materials such as bubble film or EPE foam into finished protective bags with sealed edges and standardized dimensions.

A professional bubble bag making machine integrates multiple processing steps into a continuous workflow, including feeding, sealing, cutting and collection. By automating these processes, manufacturers can achieve consistent quality, high output, and reduced labor dependency.

From a functional perspective, a bubble bag machine is not limited to one product type. Modern systems can process various materials and formats, enabling the production of air bubble pouches, EPE foam bags, perforated roll bags, courier bags, and even inflatable air column packaging. This flexibility allows manufacturers to serve diverse industries such as electronics, furniture, logistics, and consumer goods.

How Does an Air Bubble Bag Machine Work

The magic of a high-performance bubble bag machine lies in its automated precision and ability to handle delicate materials like bubble film and EPE foam without compromising their structural integrity.

• Unwinding and Tension Control: The process begins at the unwinding unit, where a massive roll of bubble film or EPE foam is fed into the system. This stage is critical for the entire production line; a professional air bubble bag machine uses advanced sensors and an electromagnetic brake system to maintain perfectly balanced tension. If the material is too loose, the seals will be crooked or misaligned; if it is too tight, the delicate bubbles might pop, or the film may stretch and deform.

• Sealing and Forming: Once the film is stabilized, it moves to the sealing and forming stage. High-temperature sealing heads press down on the folded film to create the sides and bottom of the pouch. Depending on whether you are using a standard air bubble bag machine or a specialized EPE foam bag making machine, the sealing temperature is precisely controlled via a PLC system to ensure the pouch is airtight and the seals are virtually unbreakable under pressure.

• Precision Cutting: After the bag structure is formed, the cutting unit uses a synchronized precision blade to separate the continuous film into individual bags. This stage requires extreme accuracy to ensure every bag meets the exact dimensions set in the control panel.

• Automatic Collection and Stacking: The finished products are moved to a dedicated collection table. Modern air bubble bag making machine designs, particularly those from a top-tier bubble bag machine supplier, often include automatic counting and stacking features. This organizes the bags neatly, reducing manual labor and allowing for immediate quality inspection and bulk packaging.

Types of Bubble Bag Machines

Different packaging needs require different machine configurations. Understanding the main types of bubble bag machines helps buyers select equipment that aligns with their product range and market demand.

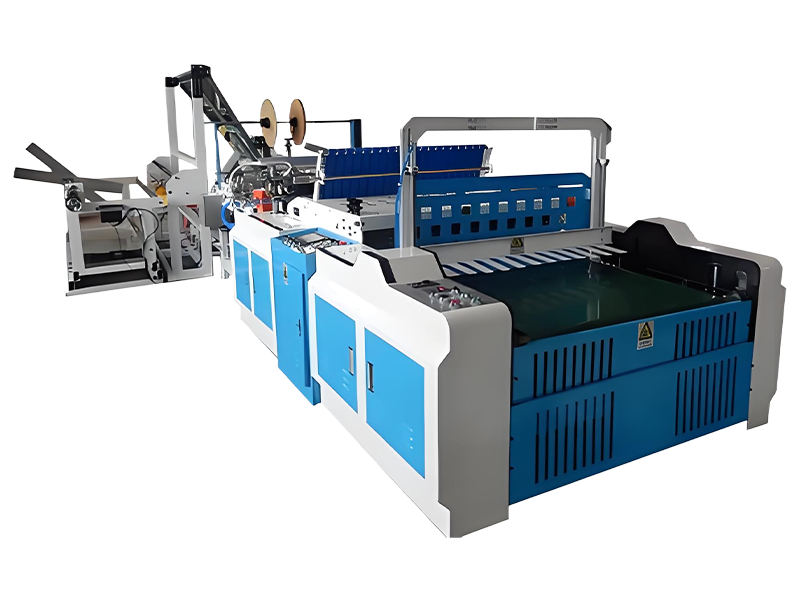

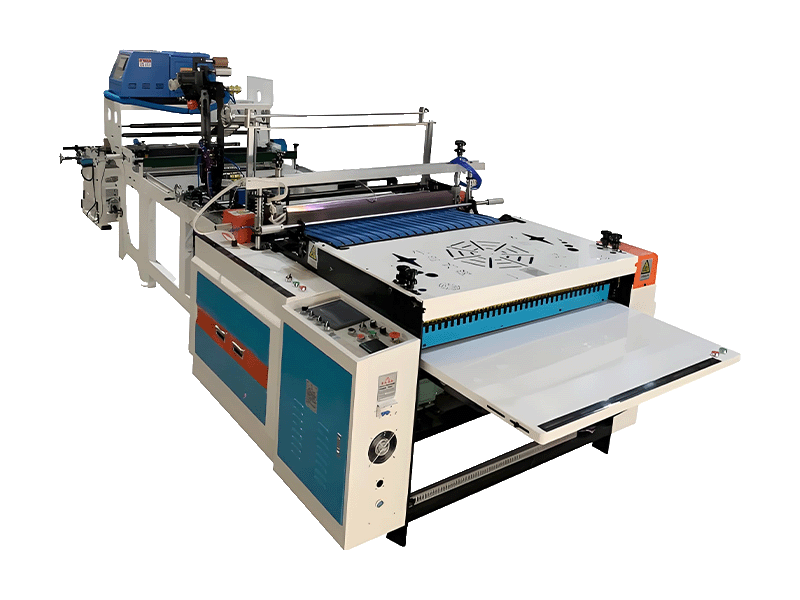

1. Two Seal Side EPE Foam and Bubble Bag Making Machine

This specific air bubble bag machine is a high-efficiency marvel. It specializes in producing double-sealed bags from either EPE foam or bubble film. What makes this bubble bag making machine stand out is its “two-out” production capability. It can produce two bags simultaneously, reaching speeds of up to 100 bags per minute. For a high-volume bubble bag machine supplier, this level of throughput is essential for meeting tight deadlines.

2. Three Seal Side EPE Foam and Bubble Bag Making Machine

When size matters, the three-seal air bubble bag making machine takes the lead. This machine is optimized for large-scale packaging, often handling widths of 1500 mm or even 2000 mm. It uses a unique hot wheel bottom-sealing method and a reinforced water jet treatment to ensure that even the largest bags maintain their structural integrity. It is the go-to bubble bag machine for packaging furniture or large industrial components.

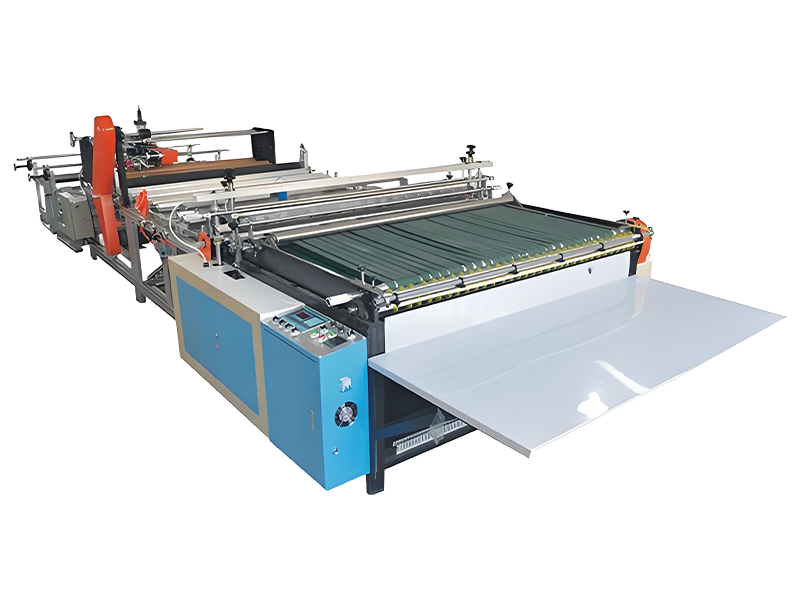

3. Air Bubble Film Perforation Bag Making Machine

For e-commerce applications where speed is everything, the perforation air bubble bag machine is ideal. It produces rolls of bags with easy-tear lines. Instead of individual pouches, you get a roll where a worker can simply "snap" a bag off and use it instantly. This bubble bag making machine type significantly reduces the time spent on manual sorting in the packaging line.

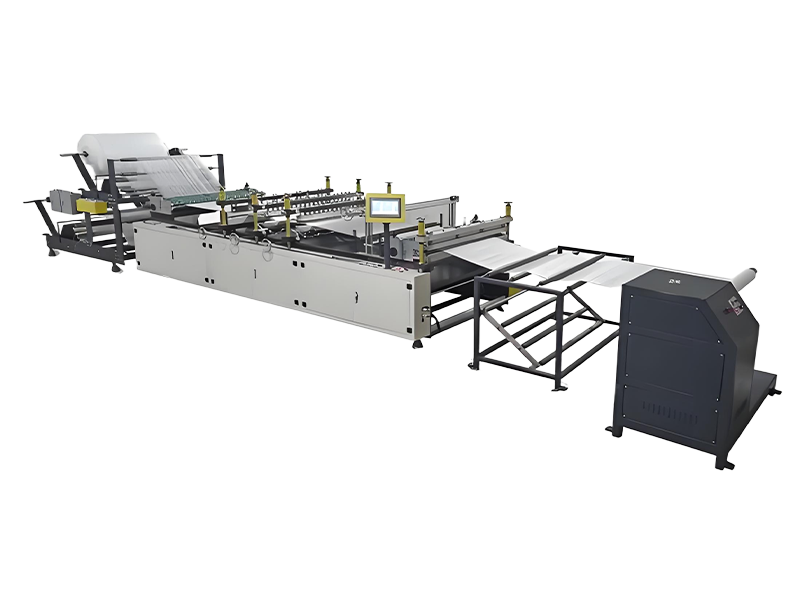

4. Courier Bag Making Machine

The courier bag making machine is designed for the heavy-duty needs of the logistics industry. Unlike a standard bubble bag machine, this equipment often processes multi-layer films, including waterproof PE and CPP. It integrates edge sealing and bottom sealing with the option to add self-adhesive tape strips. This ensures that the air bubble bag machine produces a tamper-evident, water-resistant shipping solution.

5. Buffer Air Column Bag Making Machine

When standard bubbles aren't enough, the air column bag machine provides the ultimate protection. This machine creates bags that consist of multiple independent air columns. If one column is punctured, the others stay inflated. An air column bag machine is highly technical, requiring precise heat-sealing to ensure each column is perfectly airtight, making it the gold standard for shipping fragile items like wine bottles or high-end laptops.

Advantages of Ztech Bubble Bag Making Machines

The competitive edge of an air bubble bag making machine from Ztech lies in its blend of advanced automation and sustainable design.

• Micro-Millimeter Precision via Advanced PLC: While many options on the market struggle with seal consistency at high speeds, every Ztech bubble bag making machine utilizes advanced PLC systems. This technology maintains micro-millimeter precision during the sealing and cutting phases, leading to fewer wasted materials and significantly higher profit margins for the manufacturer.

• Intuitive User Experience: Ztech prioritizes the operator’s efficiency through a high-definition touch-screen interface. This system allows users to change bag lengths, widths, and sealing temperatures in seconds, minimizing downtime during product changeovers—a critical feature for any bubble bag machine supplier serving high-volume clients.

• Commitment to Sustainability: As a forward-thinking global bubble bag machine supplier, Ztech integrates energy-saving components into every air bubble bag making machine. These innovations reduce electricity consumption by up to 20% compared to traditional models, helping businesses achieve a more sustainable and cost-effective production line.

• Superior Seal Strength: By utilizing high-grade heating elements and precision pressure control, the air bubble bag machine ensures that every seal is airtight and burst-resistant. This reliability is essential for protecting high-value goods during the rigors of long-distance logistics.

Various applications of Air Bubble Bag Machine

Air bubble bag machines are widely used across multiple industries due to their flexibility, material compatibility, and strong protective performance.

1. Electronics and Electrical Components Packaging

The electronics industry is one of the largest users of air bubble packaging. Products such as smartphones, circuit boards, sensors, chargers, and precision electronic components are extremely sensitive to impact, vibration, and static electricity.

An air bubble bag machine enables manufacturers to produce consistently sealed bubble bags that provide effective shock absorption and surface protection during storage and transportation. Compared with manual packaging, machine-made air bubble bags offer uniform thickness and reliable sealing, significantly reducing product damage rates and return costs.

2. E-Commerce and Logistics Fulfillment

With the rapid growth of e-commerce, logistics efficiency and parcel protection have become critical performance indicators. Bubble bags are widely used in fulfillment centers to package clothing, accessories, cosmetics, books, and small consumer goods.

Using a bubble bag machine, logistics suppliers can produce air bubble bags in standardized or customized sizes to fit different product categories. When combined with roll-type perforated bubble bags, packaging staff can quickly tear and use bags on demand—improving packing speed and reducing labor intensity in high-volume operations.

3. Furniture, Glass, and Building Materials Protection

Large, heavy, or fragile items such as glass panels, furniture parts, ceramic tiles, and decorative boards require higher cushioning performance and stable bag structures.

Three-seal side bubble bag machines are especially suitable for these applications, as they can produce large-format air bubble bags with reinforced sealing. By using double-layer bubble film or thicker EPE foam, the machine ensures strong impact resistance and prevents edge breakage during long-distance transportation.

4. Industrial Parts and Mechanical Components Packaging

Industrial products such as metal fittings, molds, valves, tools, and automotive components often have irregular shapes and sharp edges. Improper packaging can easily cause scratches, deformation, or collision damage.

An air bubble bag machine allows manufacturers to customize bag dimensions and material thickness, creating protective packaging that fits industrial components precisely. Compared with traditional cartons alone, air bubble bags provide additional cushioning and reduce internal movement during transit.

5. High-Value and Fragile Goods with Air Column Packaging

For products that require advanced protection, such as wine bottles, medical equipment, glassware and luxury items, traditional bubble bags may not be sufficient to meet the requirements.

In such cases, an air column bag machine produces inflatable air column packaging that provides 360-degree cushioning. This application significantly reduces breakage rates while minimizing material usage, making it a cost-effective solution for high-value shipments.

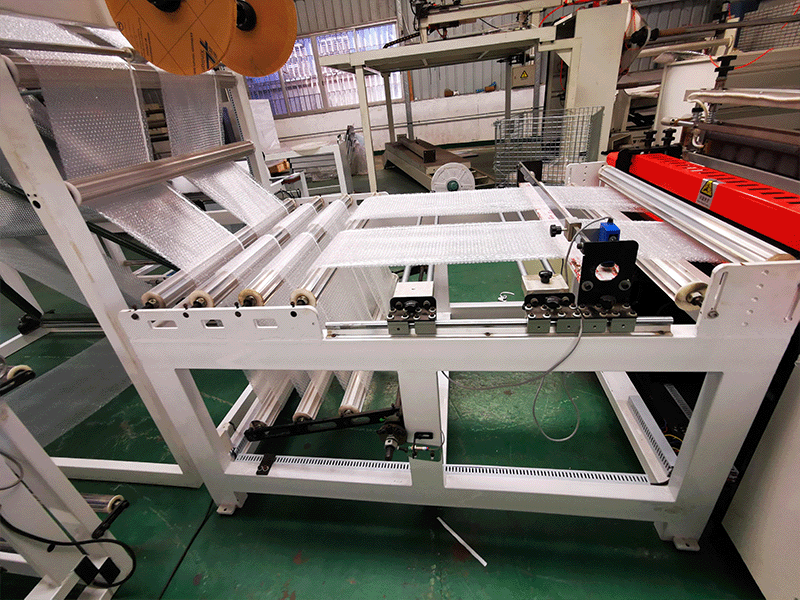

air bubble and epe foam bag making machine

Factors to Choose the Suitable Bubble Bag Machine

For manufacturers and packaging converters, evaluating a professional air bubble bag machine requires a systematic analysis of production needs, material compatibility, and automation level. The following key factors should be carefully considered before making a purchase.

1. Target Packaging Products and Bag Specifications

The first and most fundamental factor is the type of packaging products you plan to produce. Different products require different bag sizes, sealing structures, and material thicknesses.

A suitable bubble bag machine should support the required bag width, length, and sealing format (two-side seal, three-side seal, or perforated roll type). For businesses serving multiple industries, machines with flexible parameter adjustment offer higher long-term value and reduce the need for frequent equipment replacement.

2. Material Compatibility and Processing Capability

Not all machines handle materials in the same way. Some are optimized for standard bubble film, while others are designed to process EPE foam, laminated films, or multi-layer materials.

When selecting an air bubble bag machine, it is essential to confirm material thickness range, tension control capability, and sealing performance. Strong material compatibility ensures stable production and minimizes defects such as weak seals or material deformation.

3. Production Capacity and Efficiency Requirements

Production volume directly determines the machine configuration you need. Small-scale manufacturers may prioritize flexibility, while medium and large-scale operations often focus on speed and continuous output.

High-efficiency bubble bag machines, such as dual-output or high-speed models, significantly increase output per hour. Choosing a machine that matches your actual production demand helps avoid both underutilization and capacity bottlenecks.

4. Sealing Quality and Product Consistency

Sealing strength is a critical quality indicator for air bubble bags. Poor sealing can lead to air leakage, moisture penetration, and product damage during transport.

A reliable air bubble bag machine should feature precise temperature control, stable pressure application, and uniform sealing performance. Consistent sealing quality not only improves packaging reliability but also enhances brand credibility for packaging suppliers.

5. Automation Level and Ease of Operation

Modern packaging production increasingly relies on automation to reduce labor costs and human error. Machines equipped with microcomputers or servo control systems allow operators to adjust parameters quickly and accurately.

An easy-to-operate bubble bag manufacturing machine can shorten the training time, reduce the reliance on operators, and enhance the overall production stability. This is particularly important for factories with frequent staff turnover.

6. Customization Capability and Future Scalability

Market demand is constantly changing. Packaging manufacturers often need to adapt to new product sizes, materials, or customer requirements.

Choosing a bubble bag manufacturing machine with a personalized settings feature can ensure that your equipment remains highly efficient as your business expands, thereby safeguarding your long-term investment.

air bubble film perforation bag machine

Maintenance Tips of Air Bubble Bag Machine

A professional bubble bag machine operates continuously under heat, pressure, and mechanical movement. Without systematic maintenance, sealing performance may degrade, downtime may increase, and overall production costs can rise. The following maintenance tips help manufacturers keep their air bubble bag machines running efficiently and reliably.

1. Daily Inspection and Cleaning

Daily inspection is the foundation of effective maintenance. Before and after each production shift, operators should check key components such as sealing heads, cutting blades, guide rollers, and electrical connections.

Dust, melted film residue, and debris should be cleaned regularly from the sealing area. Keeping the sealing surface clean ensures uniform heat transfer and prevents weak seals or uneven edges on air bubble bags.

2. Sealing System Maintenance

The sealing system is the core of any air bubble bag machine. Over time, sealing heads may accumulate residue or experience uneven heating due to long-term high-temperature operation.

Regularly inspect sealing temperature accuracy and pressure balance. If sealing quality declines, recalibration or replacement of heating elements may be necessary. Proper sealing maintenance directly affects bag strength, airtightness, and moisture resistance.

3. Cutting Unit and Blade Care

Cutting blades are critical for achieving clean, consistent bag edges. Dull or damaged blades can cause burrs, irregular cuts, or material tearing.

To maintain cutting accuracy, blades should be inspected frequently and sharpened or replaced according to production intensity. Well-maintained cutting units improve product appearance and reduce material waste.

4. Lubrication of Moving Parts

Mechanical components such as bearings, chains, guide rails, and transmission parts require proper lubrication to minimize friction and wear.

Use recommended lubricants and follow lubrication schedules provided by the bubble bag machine manufacturer. Adequate lubrication reduces noise, improves motion stability, and extends component lifespan.

The Trend of Air Bubble Bag Making Technology

The technology behind air bubble bag making machines is evolving rapidly, driven by increasing automation, sustainability demands, and the need for higher production efficiency.

1. Energy-Saving Design and Sustainable Manufacturing

Sustainability has become a global priority in packaging production. New-generation air bubble bag machines focus on reducing energy consumption through optimized heating systems, intelligent temperature control, and efficient motor configurations.

At the same time, machines are being designed to support recyclable and eco-friendly materials, including thinner bubble films and recyclable EPE alternatives. By improving material utilization and minimizing waste, modern bubble bag machines help manufacturers comply with environmental regulations while controlling costs.

2. Greater Flexibility and Customization Capability

Market fragmentation and personalized packaging demand have driven machines toward greater flexibility. Modern bubble bag machines are designed with modular structures that allow optional functions such as perforation units, special sealing patterns, or size expansion modules.

This flexibility enables manufacturers to respond quickly to customer requirements without investing in multiple standalone machines, significantly improving production adaptability and ROI.

3. Integration with Smart Manufacturing and Data Monitoring

Bubble bag machines are increasingly integrated into smart manufacturing systems. Real-time data monitoring allows manufacturers to track output, energy consumption, machine status, and maintenance needs.

This data-driven approach supports preventive maintenance, reduces unexpected downtime, and enables continuous production optimization, making air bubble bag machines smarter and more reliable production assets.

4. Improved Sealing Precision and Product Consistency

Sealing quality remains the core performance indicator for any air bubble bag machine. Technological advancements in heating elements, pressure control, and sensor feedback systems have greatly improved sealing precision.

Uniform sealing ensures airtight edges, consistent bag dimensions, and long-term durability during transportation. For packaging brands, this consistency directly translates into higher customer trust and reduced after-sales claims.

Ztech is committed to leading this technological charge as your preferred bubble bag machine supplier.

air courier bag machine machine

Conclusion

In a competitive packaging market, investing in the right bubble bag machine is a strategic decision that directly affects efficiency, quality, and profitability. From standard air bubble bags to advanced air column packaging, modern machines offer unmatched versatility.

As a professional bubble bag machine supplier, Ztech combines engineering expertise, reliable equipment, and customer-oriented service to support global packaging manufacturers. Choosing Ztech means choosing a long-term partner for sustainable packaging production.

FAQ

Q1: What is the difference between a bubble bag machine and an air column bag machine?

A1: A bubble bag machine produces sealed cushioning bags from bubble film or EPE foam, while an air column bag machine creates inflatable air chambers for higher impact protection.

Q2: Can one air bubble bag machine handle different materials?

A2: Yes. Most modern machines support multiple thicknesses of bubble film and EPE foam with adjustable parameters.

Q3: How do I choose a reliable bubble bag machine supplier?

A3: Look for technical expertise, customization capability, after-sales support, and proven industry experience.

Q4: What is the average speed of a bubble bag making machine?

A4: A standard bubble bag machine usually produces between 60 to 100 bags per minute, depending on the bag size and the machine's configuration.

Q5: What materials are compatible with an air bubble bag machine?

Standard machines mainly work with LDPE and HDPE bubble film. Some advanced models also support laminated materials, co-extruded films, and anti-static bubble films for electronics and precision components.

Q6: How long is the service life of a bubble bag making machine?

With proper maintenance, a high-quality bubble bag making machine can operate reliably for 8–15 years. Regular inspection, timely replacement of wear parts, and correct operation are key to extending machine lifespan.