Description

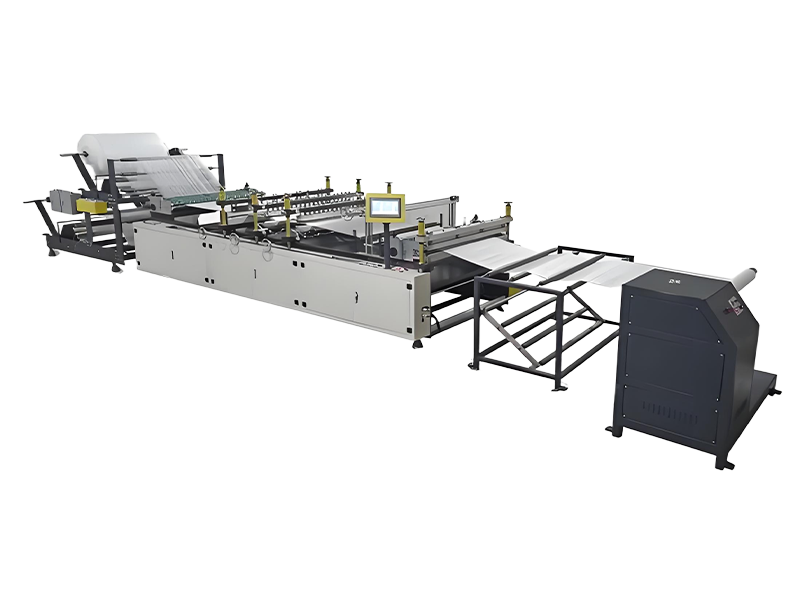

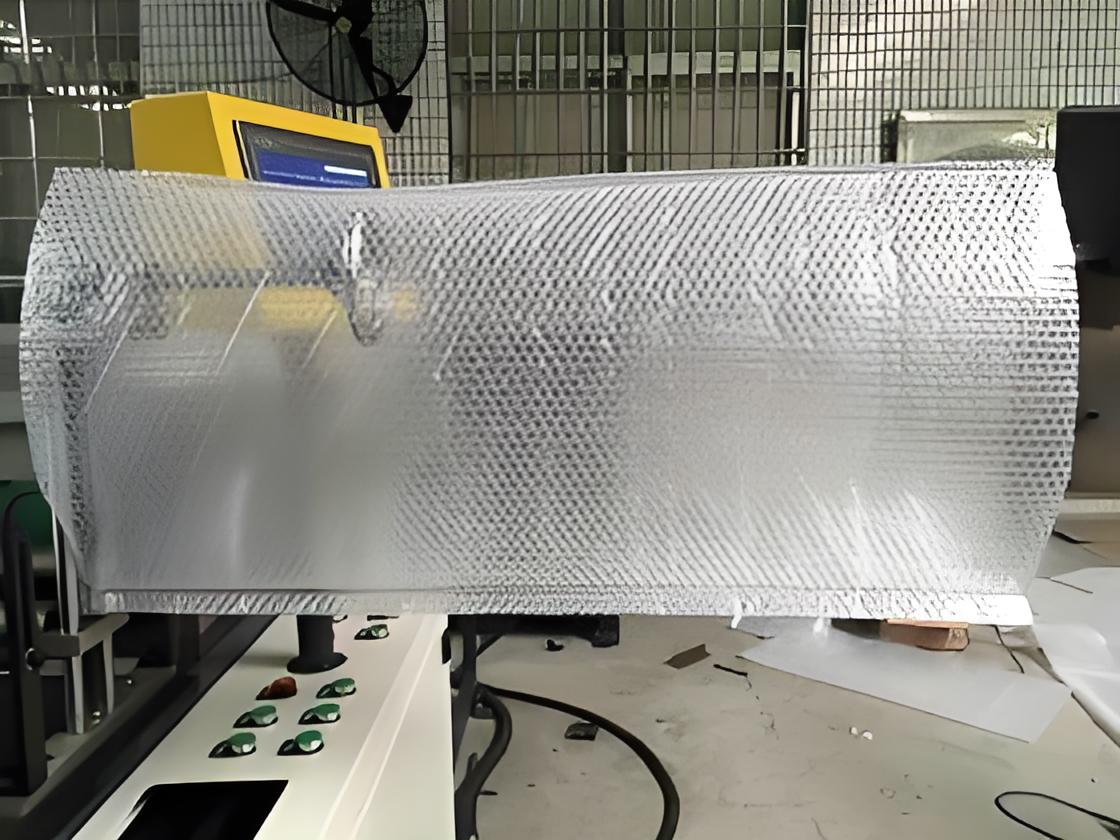

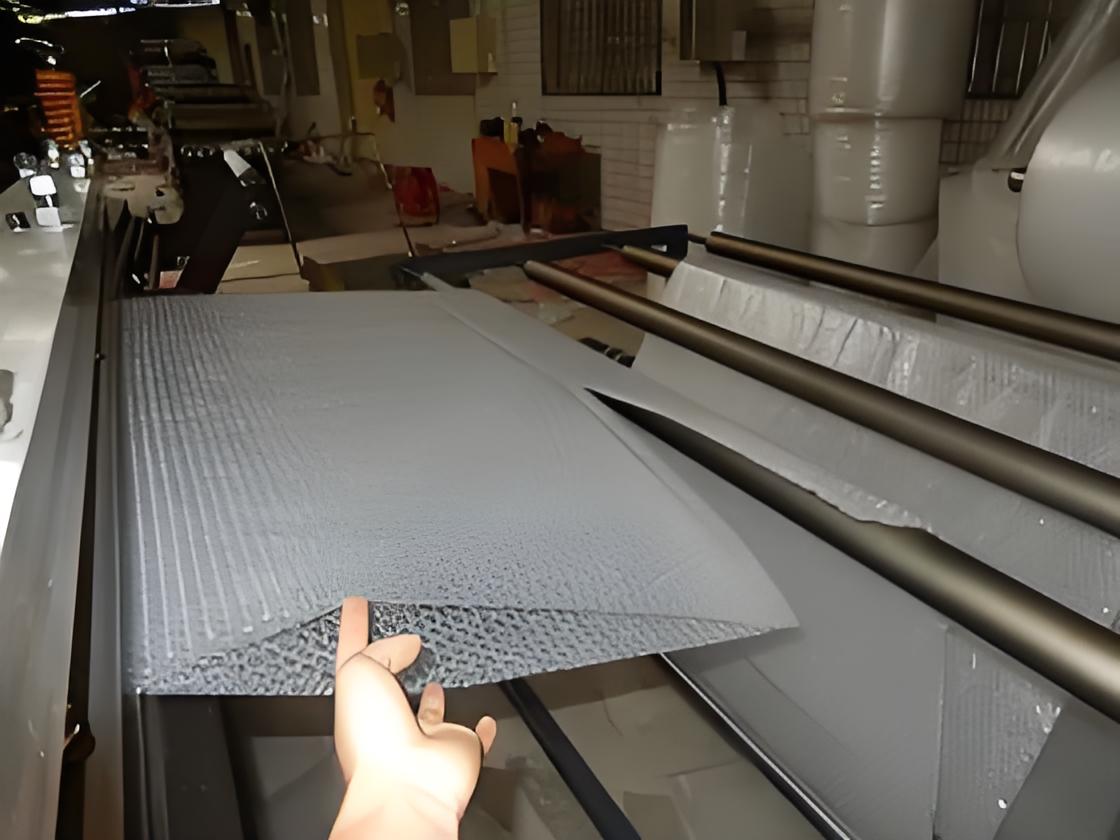

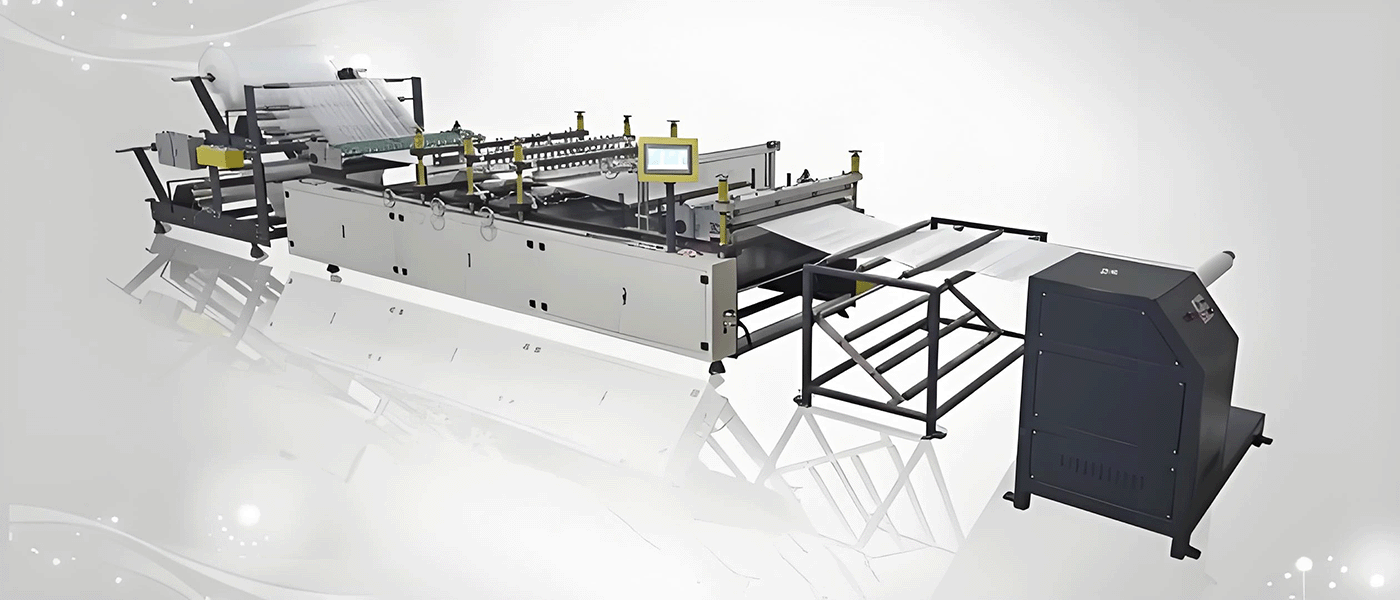

As a specialized automated equipment, this Air Bubble Film Perforation Bag Making Machine focuses on producing roll-type perforated bubble bags. It processes bubble film through precise punching, heat-sealing forming, and other processes, turning it into roll-type products with pre-punched perforation lines.

Users can quickly obtain individual bubble bags by simply tearing along the perforations, which boosts packaging convenience. The roll-type finished products are easy to store and use on-site. Moreover, it supports customization of bag size, perforation spacing, and roll length to meet diverse packaging needs of different products.

Features

- Precise Perforation, Easy Tearing: Adopts high-precision punching dies, ensuring uniform perforation spacing. The torn edge is smooth without burrs, and the bags can be torn with one hand for quick use.

- Flexible Customization: Supports customization of bubble bag size, perforation spacing, and roll length, adapting to the packaging requirements of small accessories, daily necessities, and other different products.

- Stable and Reliable Operation: Controlled by a micro-computer, it enables frequency control of motor speed and stepper dragging; the machine can also be customized with a servo control system for more precise operation.

- Efficient Mass Production: Integrates punching, heat-sealing, and rolling processes, realizing continuous mass production of roll-type perforated bubble bags, significantly improving packaging production efficiency.

- User-Friendly Design: Roll-type finished products are convenient for storage and on-site extraction, reducing the time for arranging individual bags and simplifying the packaging workflow.

Technical Parameters

| Suitable Material | Air Bubble Film |

| Maximum Speed (meter/minute) | 20-50 bags / minute (it depend on the bag size |

| Tube Sealing | 1600mm |

| Maximum Width | 1600mm |

| Tube opening side | Max. 1000mm |

| Power Supply | 380 V, 50 Hz / 3 Phase |

| Total Power | 30kw |

| Heating Power | 20kw |

| Consumption Power | 12kw |

| Weight | 5000kg |

| Length Error Valve | + - 0.5mm |