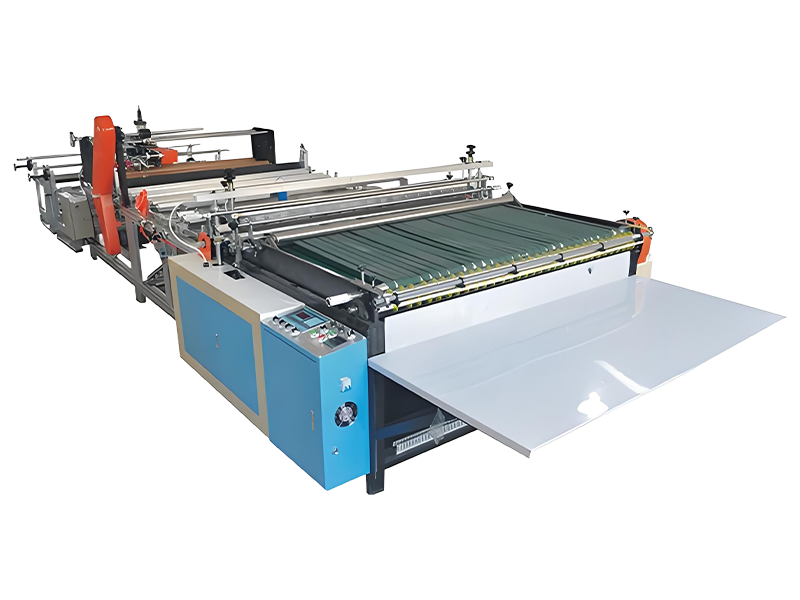

Description

As a professional three-seal bag-making equipment, it follows a "material stacking → heat-sealing → cutting" workflow. First, two layers of bubble film (or EPE foam) are stacked; then, hot wheels heat-seal the bottom and two sides to form a three-sealed structure.

For 1.5m-wide bags, it adopts special reinforced water jet treatment to enhance sealing stability. The machine is optimized for large sizes, avoiding deformation during processing, and produces bags with neat, tight seals—suitable for packaging large items.

Features

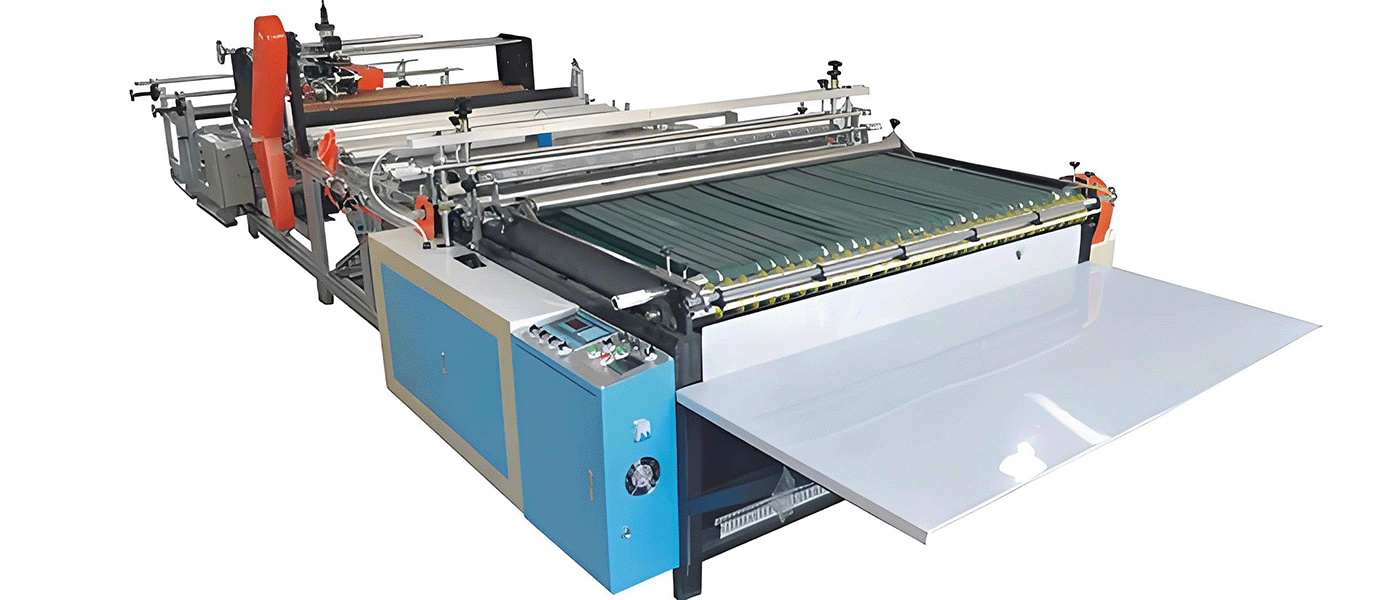

- Three-seal structure production: Specializes in making three-sealed bags from EPE foam and bubble film, providing all-around protection for large packaged items.

- Large-size compatibility: Focuses on producing big bags (1500mm, 2000mm, etc.), meeting the packaging needs of large products.

- Double-layer material application: Uses two layers of bubble film for stacking, enhancing the bag’s cushioning performance to better protect fragile large items.

- Hot wheel bottom sealing: Relies on hot wheels for bottom heat-sealing, ensuring firm sealing and preventing material leakage or breakage.

- Special reinforced water jet treatment: For 1.5m-wide bags, this treatment strengthens the seal edge, improving sealing quality and bag durability.

- Stable large-size processing: Optimized structure avoids material deformation during large-bag production, ensuring consistent bag size and shape.

Technical Parameters

| Model | ZT150-3BM |

| Raw materials | Air Bubble Film/EPE Foam |

| Maximum width | 70-1500 |

| Maximum length | 70-1000 |

| Production Capacity | 30-80 per unit |

| Total Power | 8 |

| Total Weight | 1800 |