With the rapid development of the global e-commerce and logistics industries, the demand for packaging materials has reached unprecedented levels. As a lightweight, transparent packaging material with excellent cushioning properties, bubble film plays an indispensable role. The core equipment for producing this critical packaging material is the air bubble film machine. This equipment, also commonly referred to as a bubble film making machine, is a complex industrial apparatus that integrates plastic extrusion, vacuum forming, and composite technology. This article will delve into the working principles, classifications, and core technical factors to consider when selecting a bubble film extrusion machine.

Key Components of Air Bubble Film Making Machine

The bubble film making machine is a mechanical device that uses the extrusion molding process to seal air between two or more layers of plastic films to form bubbles. Its basic principle is to use high-pressure vacuum to suck the molten film into the holes of the forming roller and then combine it with another base film.

A high-performance bubble film making machine is a complex integrated system composed of multiple precision components. Its core elements include the extrusion system, forming die, vacuum forming system, laminating system, and automated control system. The coordinated operation of these components determines the finished film's thickness uniformity, bubble saturation, and production speed.

1. Extrusion System

The extrusion system is the core of the bubble film extrusion machine. Unlike the traditional single-screw design, high-performance equipment usually adopts a dual-screw or multi-screw configuration. For example, when producing 2-layer bubble films, the dual-screw design can achieve independent control of the thickness of the bubble layer and the base film layer. This independent control not only enhances the flexibility of production but also reduces costs by precisely distributing the material ratio. The material of the screws is usually made of high-quality alloy steel and undergoes nitriding treatment to ensure extremely high wear resistance and uniform plasticization when processing 100% recycled materials.

2. Precision T-type Die

The T-type die ensures uniform film thickness. In co-extrusion bubble film machinery, the die needs to handle various molten materials from different extruders. High-end die adopts a high-precision frame-type flow channel design and is equipped with bidirectional thickness adjustment screws. This design can control the film thickness error within an extremely small range, effectively solving the common problems of glue leakage and uneven output in the industry.

3. Bubble Forming Roller System

This is the most technically sophisticated component of the air bubble film machine. The forming roller integrates an extremely complex vacuum system and cooling system. Its surface is covered with wear-resistant special steel plates. To ensure stable bubble shape during mass production, a dual-tube cooling system is typically employed inside the roller. This efficient heat exchange mechanism guarantees rapid bubble formation without collapse, even at high rotational speeds (up to 80m/min or even 100m/min).

4. Automation Control and Safety Protection

Modern automatic bubble film machines typically employ PLC and touch screen human-machine interfaces. This enables operators to monitor the temperature zone, screw rotation speed, and production line speed in real time. At the same time, a strict safety system, including instantaneous stop buttons and sensor-based barriers, provides comprehensive protection for the operators.

How Does an Air Bubble Film Machine Work

The air bubble film machine melts the raw materials through a hot extrusion process, and then uses vacuum negative pressure technology to capture air on the rotating mold at high speed, completing the thermal fusion bonding between layers. This process requires the equipment to maintain absolute synchronization under high temperature and high pressure conditions.

• Feeding and Plasticizing: First, the plastic granule raw materials are sent into the hopper of the extruder by an automatic feeding machine. Inside the barrel, the screw starts to rotate. Through shearing and the action of external heaters, the solid particles are gradually heated, compressed, melted and plasticized into a uniform viscous melt. The temperature control during this process is extremely crucial and directly affects the physical properties of the final film.

• Extrusion for Film Formation: After being fully plasticized, the molten material is pushed by the screw and extruded to the die head. Through the precise flow channel design inside the die head, the molten material is uniformly extruded to form a flat and smooth film. This is the "base layer" or "surface layer" of the bubble film. For a multi-layer bubble film machine, there may be multiple extruders working simultaneously, extruding films of different materials or colors respectively.

• Vacuum Forming: The freshly extruded and still semi-molten film is immediately transported to the core forming roller. At this point, the vacuum system is activated, and the powerful suction force passes through the small holes on the surface of the forming roller, precisely adhering the film to the concave mold, instantly forming a series of neatly arranged hemispherical bubbles.

• Lamination and Cooling: Almost simultaneously, the second layer of film extruded by another extruder will cover the already formed bubble layer. Through the pressure of the pressing rollers, the two layers of materials are firmly thermally bonded together, thereby sealing the air inside the bubbles. Subsequently, the formed bubble film will undergo rapid cooling on the cooling rollers to solidify its structure and achieve stable formation.

• Tensioning and Winding: After cooling and shaping, the bubble film is conveyed forward at a constant speed through the traction device. The traction speed needs to be precisely matched with the extrusion speed to ensure stable thickness and quality of the product. Finally, the bubble film is guided to the winding system. The system will automatically cut according to the preset length and roll it up smoothly into a roll, completing the entire production process. An automatic bubble film machine can achieve unmanned operation at this stage, significantly improving production efficiency.

Different Types of Bubble Film Machines

From the perspective of application and technology, the bubble film making machine has evolved from a single structure to a multi-layer, multi-functional, and highly customized equipment system. Different types of air bubble film machines correspond to different market demands and product positioning.

2 Layers Air Bubble Film Making Machine

This is the most common and basic bubble film machine on the market. The bubble film it produces is composed of a two-layer structure of "bubble layer + PE base layer". One side of this structure is uneven with bubbles, while the other side is smooth. It is widely used in the cushioning packaging of general goods, offering high cost performance and meeting most basic shock protection requirements. It has high production flexibility, with each layer independently controllable in terms of material, formula and color.

3 Layers Air Bubble Film Making Machine

This bubble film machine manufactures a product structure comprising ‘PE film layer + bubble layer + PE base layer’, wherein the bubbles are sandwiched between two layers of smooth film. Compared to two-layer bubble film, the three-layer structure features smooth surfaces on both sides, enhancing not only its aesthetic appeal but also providing superior compression resistance and tear strength. Moreover, the smooth surface facilitates printing or lamination with other materials. Such equipment typically offers considerable flexibility, capable of producing three-layer bubble film while also being adjusted to manufacture two-layer bubble film, thereby serving multiple purposes with a single machine.

5/7 Layers Air Bubble Film Lamination Machine

These two are powerful multi-layer bubble film machines. They can not only produce standard bubble films with two or three layers, but their core advantage lies in the in-line lamination function. This means that while producing the bubble films, they can directly combine PE laminated materials, such as aluminum foil, kraft paper, EPE foam, or HDPE film, with the bubble films to form a composite material with a total of 5 or 7 layers. These composite bubble films have special functions such as heat insulation, moisture prevention, and enhanced toughness, and are widely used in high-end markets such as cold chain logistics and packaging of precision instruments.

Key Features of ZTECH Bubble Film Making Machines

Among the numerous bubble film machine manufacturers, ZTECH stands out for its outstanding technology, stable performance and customer-oriented philosophy.

1. Unparalleled Stability and High Performance

High-speed stable operation stands as the core benchmark for evaluating the quality of a high-speed bubble film machine. ZTECH equipment prioritises stability throughout both design and manufacturing. Its specialised screw design achieves superior plasticisation, maintaining consistent production even with higher recycled material ratios, thereby delivering cost savings for customers. Precision-machined forming rollers, coupled with a forced water-cooling system and a four-bearing stabilised structure, ensure uniformly plump bubble formation and superior quality even at high speeds. This meticulous attention to detail guarantees prolonged, trouble-free operation, establishing the equipment as a truly high-output bubble film machine.

2. Premium Core Components and Masterful Craftsmanship

The longevity and performance of any equipment hinge upon the quality of each component. ZTECH steadfastly employs parts from industry-leading suppliers and the finest raw materials. For instance, its die heads utilise durable, non-deforming 2311 die steel; electrical components are sourced from internationally renowned brands such as Schneider, Omron, and Delta; while cylinders utilise imported brands from Switzerland and elsewhere. These high-quality components, combined with masterful machining techniques, collectively establish the exceptional quality and extended service life of ZTECH's bubble film extrusion machines.

3. Intelligent Operation and Comprehensive Automation

To reduce operational complexity and minimise reliance on manual labour, ZTECH bubble film machines have achieved full intelligence and automation. The equipment comes standard with a PLC control system and high-definition touchscreen, featuring an intuitive interface for straightforward operation alongside intelligent fault diagnosis capabilities. From automatic feeding and precise tension control to fully automated winding, length measurement and cutting, the entire production line operates with high automation. This significantly enhances production efficiency while effectively reducing scrap rates and labour costs, making it the ideal fully automatic bubble film machine for modern factories seeking high-efficiency production.

4. Comprehensive Safety Assurance

ZTECH consistently prioritises production safety. Equipment is fitted with multiple safety protection devices, including precision sensor switches and pull-cord emergency stop mechanisms, and has secured numerous national invention patents and CE certification. The electrical circuitry features clear, standardised wiring with individually numbered circuits, greatly facilitating subsequent maintenance and fault diagnosis. Crucially, ZTECH offers global professional after-sales support, including complimentary installation and commissioning in multiple countries, remote fault diagnosis, and overseas engineer dispatch services, ensuring customers' production runs smoothly without concern.

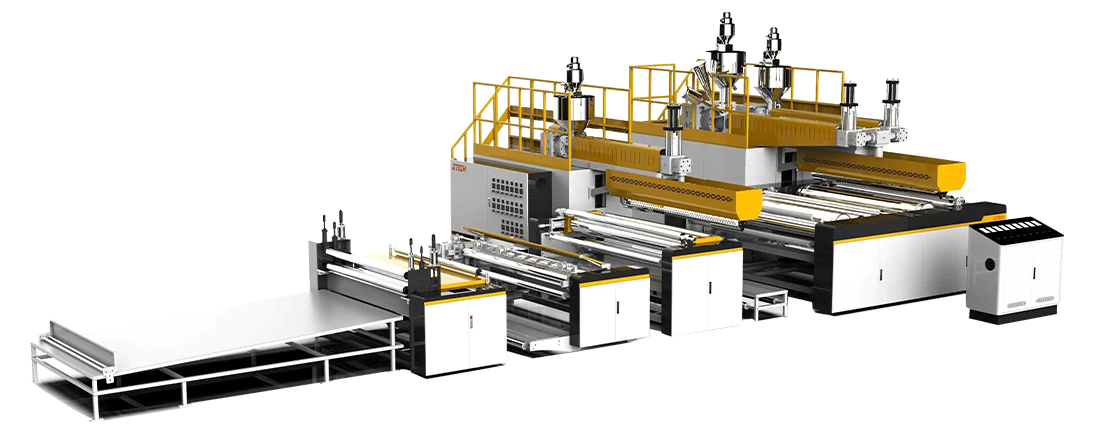

air bubble film making machine

Advanced Extrusion Technologies of ZTECH Air Bubble Film Machine

In addition to its profound accumulation in the traditional bubble film machine field, ZTECH also actively explores and applies advanced co-extrusion technology, developing high-performance co-extruded bubble film machinery that can meet the special market demands. This further consolidates its position as a leading bubble film machine manufacturer in the industry.

ABA Coextrusion Air Bubble Film Machine

This represents an innovative co-extrusion bubble film machinery. Its unique 3-in-1 co-extrusion structure enables both the bubble layer and base layer to be formed from a tri-layer material composition (PE + PP/HDPE + PE). The intermediate layer permits the incorporation of lower-cost recycled material or functionally enhanced compounds, whilst the inner and outer layers utilise pure PE to ensure excellent heat-sealing properties and visual appearance. This ABA structure substantially enhances the film's physical strength, toughness and puncture resistance without significantly increasing costs, making it an ideal choice for producing high-strength bubble film packaging bags.

Nylon Coextrusion Air Bubble Film Machine

This equipment employs a high-performance 5-in-1 co-extrusion structure, wherein both the bubble layer and base layer are precision-composited from five material layers (PE + TIE + Nylon + TIE + PE). The nylon layer serves as the core, providing exceptional gas barrier properties that effectively prevent air leakage and deflation during prolonged storage or extended transportation. TIE, the bonding resin, firmly adheres the PE and nylon layers together. The bubble film produced by this equipment boasts exceptionally long gas retention, outstanding toughness, and durability. It represents the optimal choice for packaging high-end electronic products, precision medical equipment, and valuable items requiring long-term storage or long-distance transport.

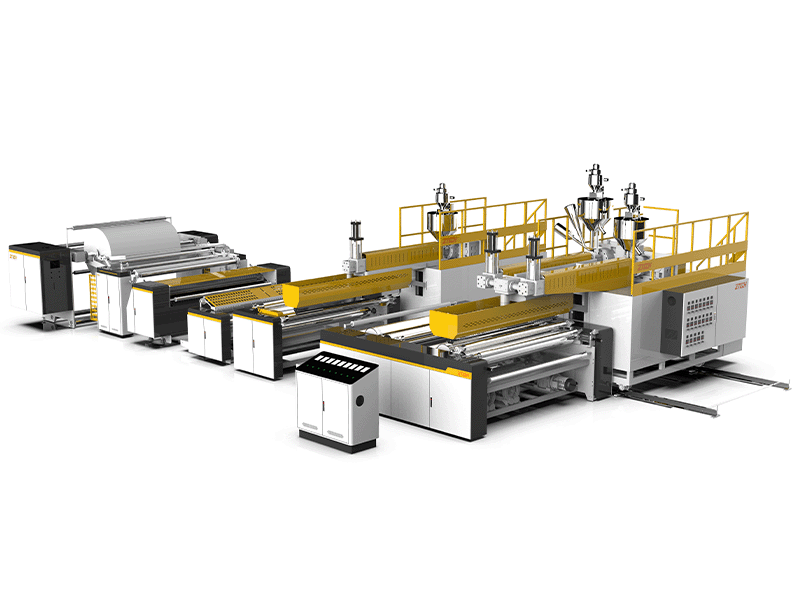

co-extrusion bubble film machine

Select the Most Suitable Bubble Film Machine

To select the most suitable equipment, it is necessary to conduct a comprehensive assessment of your specific production requirements, product positioning, budget, and future development plans.

Step One: Define Product Application and Layer Requirements

Basic Cushioning Packaging: If your primary business involves providing standard goods protection for e-commerce, removal companies, or similar sectors, a two-layer bubble film machine offers the most cost-effective solution. It delivers high production efficiency with low energy consumption, meeting the vast majority of basic packaging needs.

Enhanced Protection and Aesthetics: For packaging furniture, electronics, or items requiring smooth surfaces on both sides for subsequent processing, a three-layer bubble film machine is more suitable. Its robust construction offers superior protection, while its dual-purpose flexibility provides scope for future product upgrades.

Step Two: Consideration of Specialised Functionality

Specialised applications such as thermal insulation and moisture resistance: For target markets including cold chain logistics, building insulation materials, or industries requiring moisture-proof packaging, five-layer or seven-layer bubble film co-extrusion machines with in-line lamination capabilities present an excellent solution. These machines seamlessly integrate bubble film with materials such as aluminium foil or kraft paper, creating high-value-added functional products.

Step Three: Assessing Specialised Film Performance Requirements

High-Strength Courier Bag Applications: For courier bags used in the logistics sector, where tear resistance and puncture resistance are paramount, the ABA co-extruded bubble film machine proves indispensable. It significantly enhances product strength while maintaining cost control.

Premium Protection and Long-Term Gas Retention: For high-end electronics, precision instruments, or industries requiring extended storage, stringent demands exist for bubble film's gas retention properties. The nylon co-extruded bubble film machine stands as the sole solution. Its exceptional gas barrier performance delivers the highest level of protection for the most sensitive products.

Step 4: Determine production volume and automation level

Evaluate the production volume and labor costs to determine whether a high-output bubble film machine is needed or a standard equipment. ZTECH's equipment is renowned for its efficient and stable operation, capable of meeting various production volume requirements. Additionally, its highly automated features, such as automatic rewinding functions, can significantly reduce manual operations and lower operating costs, making it a wise choice for enterprises seeking efficient production.

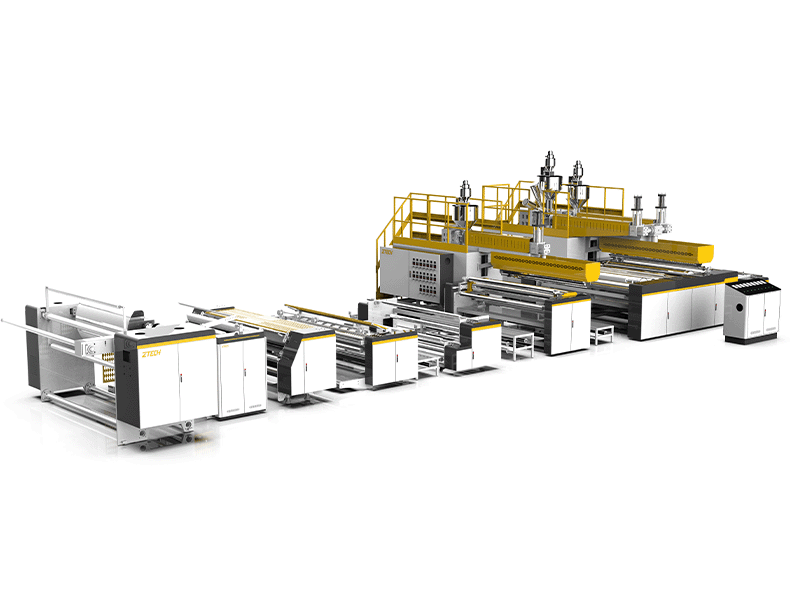

multi-layer bubble film machine

Maintenance Tips of Bubble Film Extrusion Machine

Purchasing a high-quality bubble film extrusion machine is the first step towards success, while scientific and regular maintenance is the key to ensuring its long-term stable operation, extending its service life, and continuously producing high-quality products. Here are some crucial maintenance tips.

• Regular cleaning: Maintaining equipment cleanliness is fundamental. The die head should be cleaned regularly to prevent residual materials from carbonizing and affecting the quality of the film. The forming rolls should also be cleaned regularly to ensure that the vacuum channels are unobstructed and to guarantee the bubble forming effect. At the same time, the cleanliness of the extruder screw and barrel should be maintained to prevent material degradation.

• Lubrication maintenance: According to the guidance manual provided by the equipment manufacturer, regularly add lubricating oil/grease to all moving parts of the equipment, such as gearboxes and bearings. Adequate lubrication can reduce wear, lower operating noise and energy consumption.

• Component inspection: Regularly check the wear conditions of vulnerable parts, such as heating elements, thermocouples, screws, barrel, and press rollers. If any excessive wear or damage is found, they should be replaced promptly to prevent the entire production line from stopping due to the failure of small components.

• Electrical system inspection: Regularly check whether the wiring terminals in the electronic control cabinet are loose, clean off dust, and ensure good heat dissipation. Check whether all sensors and switches are functioning properly to ensure the accuracy of the control system.

• Record and Calibration: Establish a detailed equipment maintenance log, documenting the content, time, and replaced components of each maintenance. Regularly calibrate key instruments such as temperature controllers and pressure sensors to ensure the accuracy of production process parameters. This is an important step in guaranteeing product quality consistency.

Conculsion

An air bubble film machine is a crucial investment in the packaging industry. From its precise component structure to the complex automated workflow, to the diverse models that meet different market demands, a thorough understanding of these aspects forms the basis for making an informed purchasing decision. Whether it's the basic 2-layer model or the technologically advanced nylon co-extrusion multi-layer bubble film machine, choosing a reliable and technologically advanced equipment will directly determine your product quality, production efficiency, and market competitiveness.

When choosing a partner, an excellent bubble film machine manufacturer should not only provide high-quality equipment, but also offer comprehensive technical support and reliable after-sales service. ZTECH is such a trustworthy partner. With its profound technical accumulation in bubble film making machines, the relentless pursuit of excellent quality, flexible customized service capabilities, and global customer support network, ZTECH is committed to providing each customer with solutions that exceed expectations. If you are looking for a high-performance bubble film machine, ZTECH is undoubtedly your ideal choice.

FAQ

Q1: What is an air bubble film machine used for?

A1: An air bubble film machine is used to manufacture protective air bubble film for packaging applications such as electronics, furniture, appliances, and logistics. It produces bubble film continuously through extrusion and bubble forming processes.

Q2: How does a bubble film extrusion machine work?

A2: A bubble film extrusion machine melts plastic raw materials and extrudes them through a specially designed mold. Air is introduced to form bubbles, which are then laminated, cooled, and wound into finished rolls

Q3: What is the difference between a single-layer and a multi-layer bubble film machine?

A3: A multi-layer bubble film machine can produce stronger and more functional bubble film by combining multiple material layers. Compared with single-layer machines, it offers better cushioning performance and wider application flexibility.

Q4: How do I choose a reliable bubble film machine manufacturer?

A4: A reliable bubble film machine manufacturer should offer stable machine design, advanced extrusion technology, customization capability, and long-term technical support to ensure consistent production performance.

Q5: What is the difference between a single-layer and a multi-layer bubble film machine?

A5: A multi-layer bubble film machine can produce stronger and more functional bubble film by combining multiple material layers. Compared with single-layer machines, it offers better cushioning performance and wider application flexibility.