The evolution of packaging technology has led to the development of sophisticated air bubble film making machine systems capable of producing diverse film structures. From basic two-layer wraps to high-barrier seven-layer laminates, the diversity in equipment reflects the specialized needs of different global markets. As e-commerce continues to expand, the role of an efficient air bubble film machine becomes even more critical in ensuring product safety while optimizing operational costs.

Whether you are looking for a reliable bubble film machine or an established manufacturer seeking a multi-layer bubble film machine for high-end applications, understanding the mechanical nuances is essential. This article examines the technical specifications, industrial applications, and innovative co-extrusion technology of various bubble film making machines.

The Benefits of Bubble Film Machines

Modern bubble film machine systems offer significant advantages in terms of production flexibility, cost-efficiency, and product quality. By integrating advanced extrusion technology, a high-quality air bubble film machine allows manufacturers to control every aspect of the film, from thickness to color and functional properties.

The primary benefit of a high-performance bubble film machine is the reduction of overhead costs. Traditional single-screw models often struggle with material consistency, but modern twin-screw air bubble film making machine designs allow for independent control of the bubble and base layers. This precision ensures that you only use the exact amount of resin required, directly impacting your bottom line.

Furthermore, the automation found in a contemporary bubble film making machine enhances safety and reduces labor costs. Features like automatic winding units and intelligent touch-screen control systems allow for 24 hours continuous operation with minimal supervision. For companies targeting the eco-friendly market, many air bubble film machines are designed to handle 100% recycled materials, allowing for sustainable production without sacrificing the protective qualities of the bubble wrap.

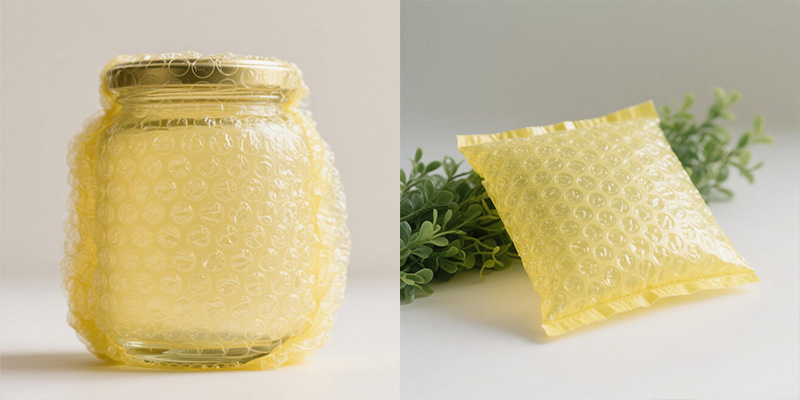

bubble film machines for recycled materials

Single-Layer vs Multi-Layer Bubble Film Machine

A standard 2-layer air bubble film machine creates a basic protective barrier, while a multi-layer bubble film machine produces films with enhanced puncture resistance and specialized functional layers for high-end industrial use.

The 2-layer bubble film machine produces a film consisting of a "bubble layer" and a "PE base layer." This is the industry standard for general-purpose wrapping. However, as the packaging requirements become more stringent, the multi-layer bubble film machine takes center stage. A 3-layer structure adds another flat PE layer on top of the bubbles, creating a "sandwich" effect that protects the air pockets from being punctured easily.

The technical complexity increases as we move to 5-layer and 7-layer systems. A multi-layer bubble film machine in these categories often incorporates lamination units to bond materials like aluminum foil or Kraft paper. This transition from a basic air bubble film machine to a complex multi-layer system allows manufacturers to enter niche markets such as construction insulation or heavy-duty electronics packaging, where standard 2-layer films would fail.

Different Layer Air Bubble Film Machines in Industrial Use

Industrial applications require specific configurations of the air bubble film making machine to achieve the desired protective or insulating properties. Each variant, from the different layer air bubble film machine, serves a unique segment of the global supply chain.

1. 2 Layers Air Bubble Film Making Machine

This air bubble film machine utilizes a twin-screw extruder to independently control the bubble and base layers. Its ability to process different formulas for each layer means you can produce a clear bubble layer with a colored base layer, adding aesthetic value to the packaging. With a production speed of up to 80 meters per minute, it is ideal for high-volume demand in the retail and shipping sectors.

2. 3 Layers Air Bubble Film Making Machine

The 3-layer version offers even greater flexibility for diverse packaging requirements. It can switch between producing 2-layer and 3-layer films without changing major components. This bubble film making machine uses a dual-twin screw system to ensure that the middle bubble layer is perfectly cushioned while the two outer PE layers provide a smooth, printable surface. This is the preferred air bubble film making machine for manufacturers producing high-quality anti-static wraps for the electronics industry.

3. 5 Layers Air Bubble Film Making Lamination Machine

When the market demands more than just plastic, the 5-layer configuration is utilized. This machine integrates in-line lamination, allowing it to bond PE-coated aluminum foil or Kraft paper directly onto the bubble film. This bubble film machine eliminates the need for secondary processing, shortening production time by 30% and significantly reducing material waste.

4. 7 Layers Air Bubble Film Making Lamination Machine

At the top of the hierarchy is the 7-layer high-end model. This advanced air bubble film making machine is designed for high-performance applications like architectural insulation. It can produce a complex “PE + Bubble + PE + Aluminum Foil + PE + Bubble + PE” structure. With integrated flame-retardant mixing systems, this bubble film machine produces materials that meet strict fire safety standards, making it an essential tool for industrial-grade construction materials.

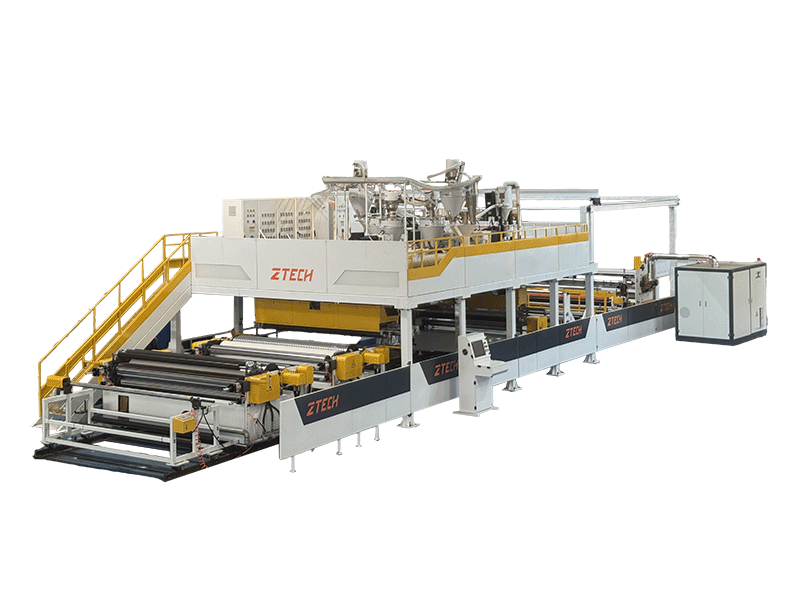

multi layer air bubble film machine

What Makes a Co-Extrusion Bubble Film Machine Stand out

In the search for higher durability and lower costs, the co-extrusion bubble film machine has revolutionized the industry by allowing different polymers to be merged into a single, high-strength film layer.

Traditional extrusion involves melting a single type of plastic (usually LDPE) to form the film. In contrast, a co-extrusion bubble film machine uses multiple screws to feed different materials into a specialized dispenser. This enables the construction of composite layers, where the properties of different materials can be combined, such as the hardness of high-density polyethylene and the flexibility of low-density polyethylene.

The co-extrusion bubble film machine stands out because it allows for “functional layering.” For example, the inner layer can be made of recycled material to save costs, while the outer layers are made of virgin resin for a premium finish and better sealability. This technical edge is why the air bubble film making machine market is shifting toward co-extrusion technology.

| Feature | Traditional Extrusion Machine | Co-Extrusion Bubble Film Machine |

| Material Structure | Homogeneous (Single material) | Composite (Multi-material layers) |

| Tensile Strength | Standard | High (Reinforced by layer bonding) |

| Cost Efficiency | Moderate | High (Supports high recycled ratios) |

| Air Retention | Standard | Superior (Especially with Nylon layers) |

| Application Range | General packaging | High-end/Technical packaging |

| Technical Complexity | Low | High (Requires precision dispensers) |

Different Types of Co-Extrusion Bubble Film Machines

Within the realm of co-extrusion, two specific models have become essential for modern packaging: the ABA co-extrusion bubble film machine and the nylon bubble film machine.

1. ABA Co-extrusion Bubble Film Machine

The ABA co-extrusion bubble film machine features a unique 3-in-1 structure. It uses a “four screws + two dispensers” configuration to merge PE, HDPE, or PP into a single layer. This bubble film machine is specifically designed for the express bag industry. By increasing the ratio of HDPE/PP in the middle layer, the resulting film is significantly harder and more puncture-resistant than standard films. This bubble film machine can produce at a speed of 100 meters per minute, making it an ideal piece of equipment for large-scale courier packaging manufacturing.

2. Nylon Bubble Film Machine

For high-end products that require long-term cushioning, the nylon bubble film machine is the gold standard. This co-extrusion bubble film machine produces a 5-in-1 structure (PE + TIE + NYLON + TIE + PE). Because nylon is much denser than air, it creates an almost impermeable barrier. While an ordinary air bubble film machine might produce a film that loses 50% of its air in 14 days, the film from a nylon bubble film machine loses only 5%. This makes it the ideal air bubble film making machine for shipping luxury goods.

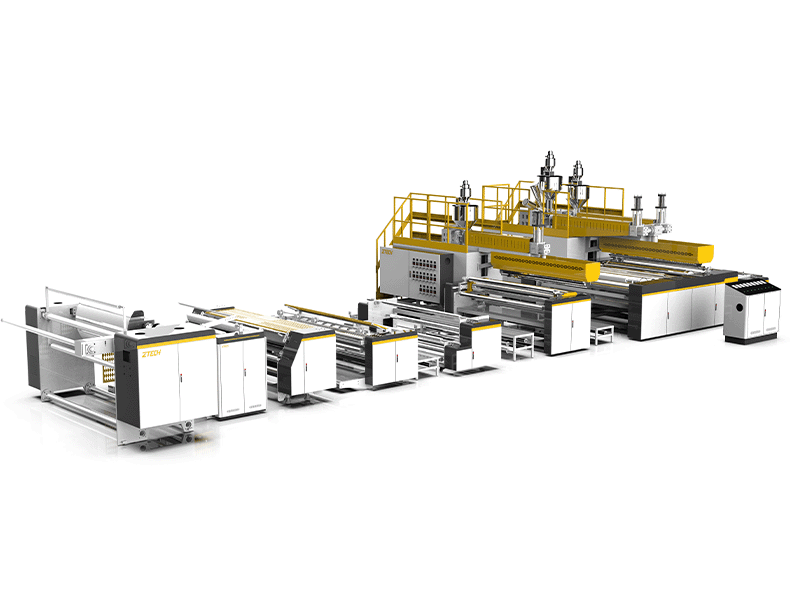

co-extrusion bubble film machine

Select the Right Air Bubble Film Making Machine for Your Business

To select the right air bubble film making machine, you must evaluate your required production speed, the necessity for lamination, and the specific material properties demanded by your customers.

The first step in selecting a bubble film machine is defining the application. If you are supplying the e-commerce sector with bubble mailers, an ABA co-extrusion bubble film machine is highly recommended due to its hardness and cost-saving integration. However, if your clients are in the cold-chain or construction industries, a multi-layer bubble film machine with lamination capabilities for aluminum foil is non-negotiable.

Secondly, consider the production scale. A high-speed air bubble film making machine that reaches 80-100 m/min requires a larger footprint and more robust power supply but offers a much faster ROI for high-volume orders. Maintenance is another factor; look for a bubble film making machine with durable components like chrome-plated lamination rollers and specialized vacuum systems in the forming cylinder. A professional air bubble film machine should also feature intelligent control systems, such as Delta touch screens, to minimize downtime through rapid fault prompting.

Conclusion

The protective packaging market is more competitive than ever, and the quality of your air bubble film machine is the primary factor in your success. From the versatile multi-layer air bubble film machine models to the highly specialized nylon bubble film machine, technology has provided manufacturers with the tools to meet any challenge.

At Ztech, we have spent decades perfecting the bubble film machine. We have continued to lead the market with innovations in speed and material efficiency. Whether you need a standard bubble film making machine or a customized multi-layer bubble film machine, Ztech provides the reliability and technical support necessary to grow your business. Choosing a Ztech air bubble film machine means investing in a legacy of precision engineering and global customer satisfaction. Contact us now for a professional consultation and a customized quote.

FAQ

Q1: What is the difference between an ABA and a standard multi-layer bubble film machine?

A1: An ABA co-extrusion bubble film machine uses a specific configuration to sandwich a different material (like HDPE) between two layers of PE, whereas a standard multi-layer bubble film machine usually layers distinct films on top of each other.

Q2: How long can bubbles produced by a nylon bubble film machine stay inflated?

A2: Thanks to the high-density barrier, a nylon bubble film machine produces wrap with a gas loss rate of only 5% over 14 days, compared to 50% for standard films, making it ideal for long-term storage.

Q3: What safety features should I look for in a bubble film making machine?

A3: A professional air bubble film machine must include emergency stop buttons that halt all circuits and cylinders instantly, as well as inductive guardrails on moving parts to protect operators.

Q4: What production speed should I expect from a modern bubble film making machine?

A4: Speed varies by model, but a professional-grade bubble film making machine typically ranges from 40m/min to 80m/min. Ztech’s advanced air bubble film making machine models have reached up to 100m/min, significantly boosting output for large-scale operations.