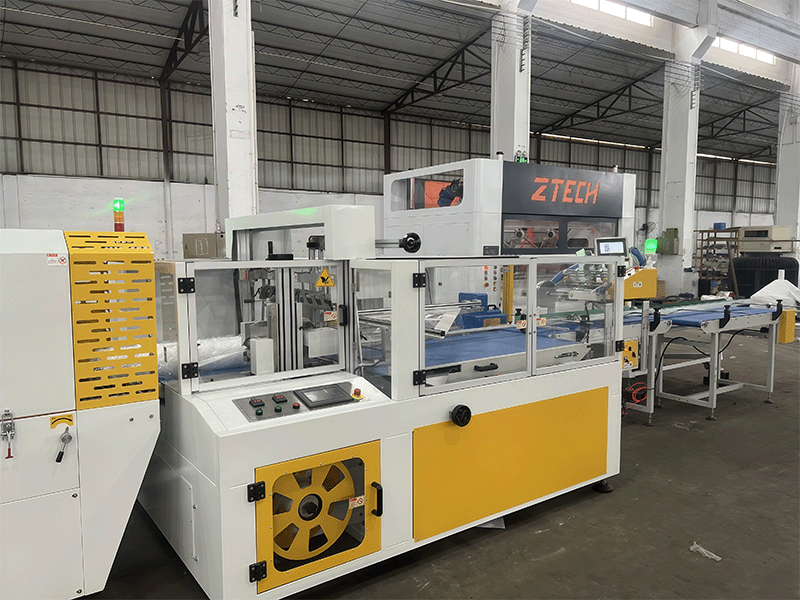

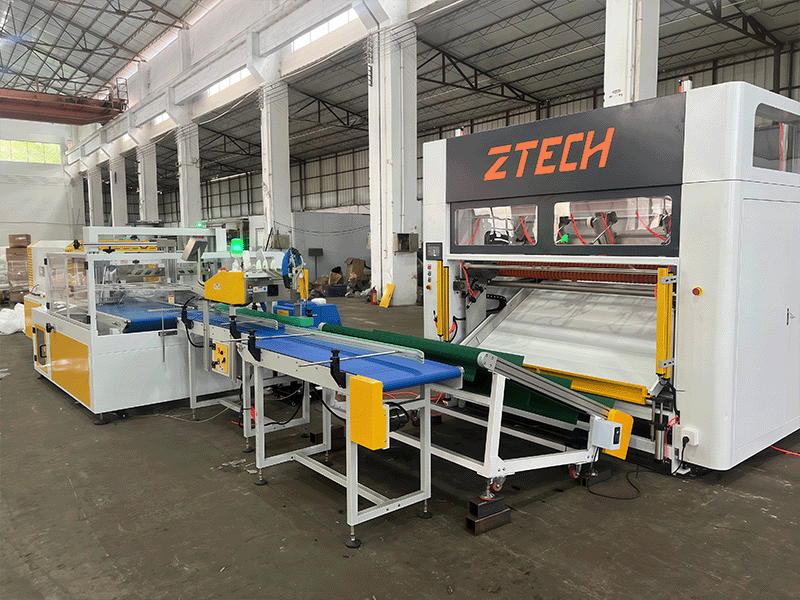

Desprition

The Air Bubble Film / EPE foam Coreless Rewinder is an automated rewinding machine designed specifically for flexible cushioning materials such as bubble film and EPE foam. Its core feature is that it can complete the regular winding of the material without the need for traditional paper or plastic cores, making it suitable for the rewinding needs of packaging material production and processing.

Features

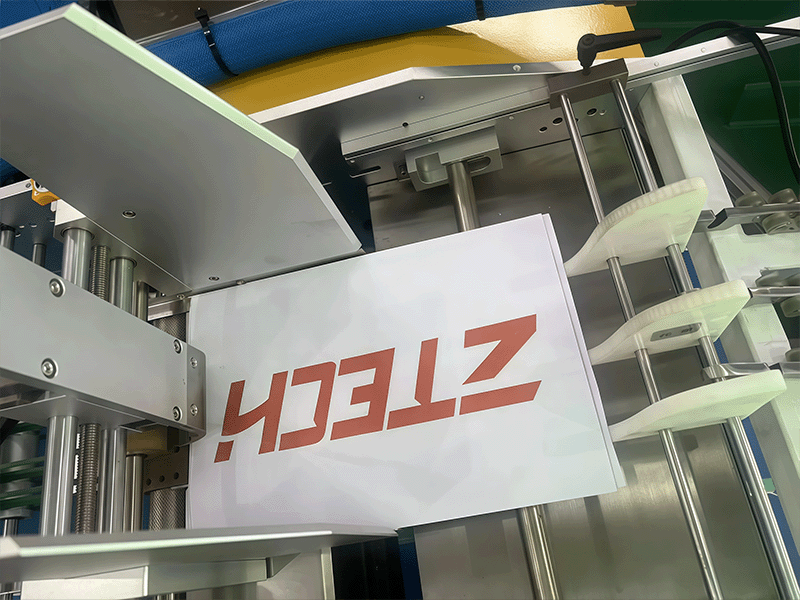

- Coreless Winding: Abandoning the traditional core shaft, the bubble film and EPE pearl cotton are directly wound into coreless rolls, reducing the cost of purchasing and replacing the core shaft, and reducing the space occupied when storing the rolls.

- Adaptive tension control: equipped with a tension adjustment system that automatically adapts the tension according to the material thickness (such as 2-30mm bubble film) to avoid material deformation or loose winding and ensure the tightness of the coil.

- High-efficiency winding: The winding speed can reach 10-30m/min (depending on the model), supporting continuous operation, which is 4-6 times more efficient than manual assisted winding and adapts to the continuous discharge rhythm of the production line

- Adjustable specifications: The winding diameter (usually up to 400mm) and roll width can be adjusted according to needs, and it is compatible with bubble films and EPE pearl cotton of different sizes.

Technical Parameters

| Model | ZT160-APC |

| Max width | 1600mm |

| Length | 3m-30m (Maximum diameter 600mm) |

| Speed | 50M/min |

| Tolerance | +-5mm |

| weight | 2100kg |

| power | 10kw |

| Power supply | 380V(three phase), 50HZ |