Description

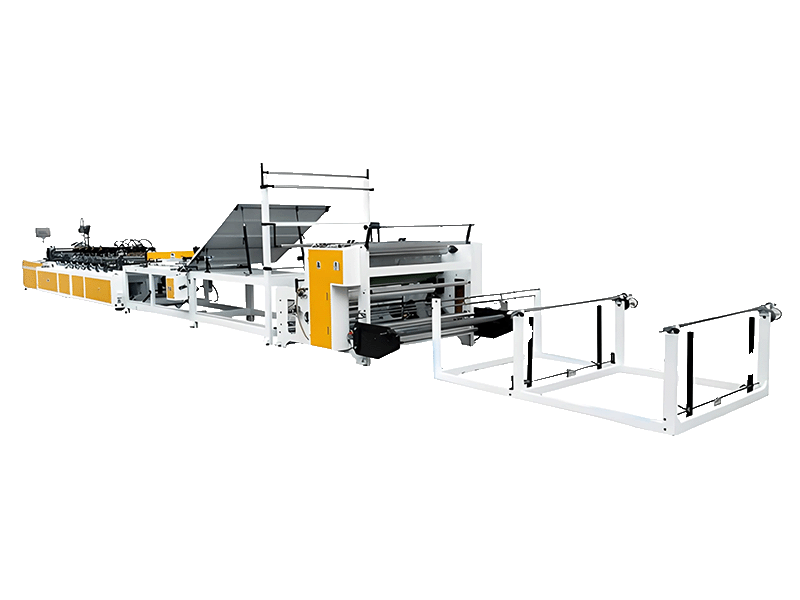

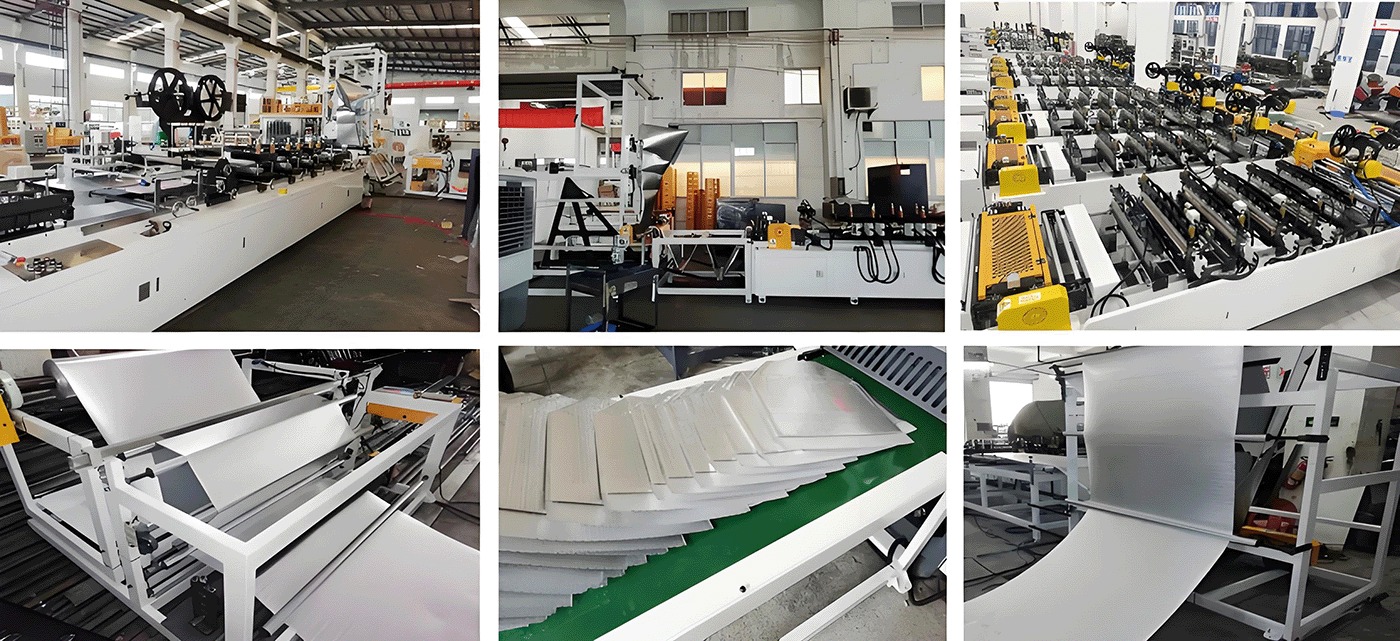

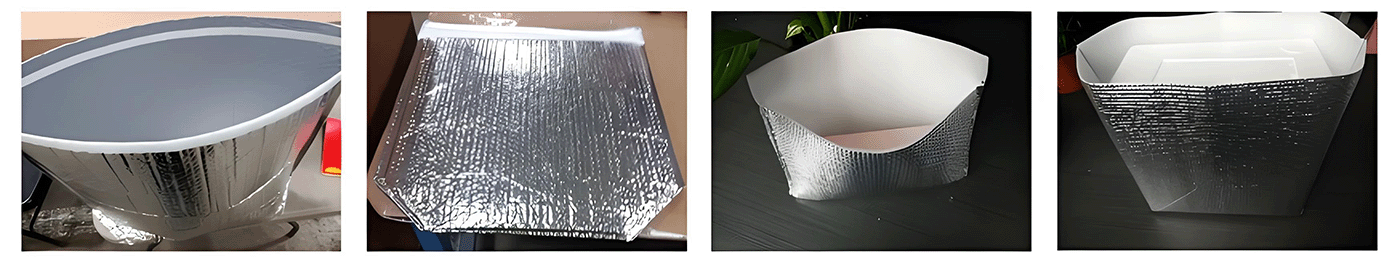

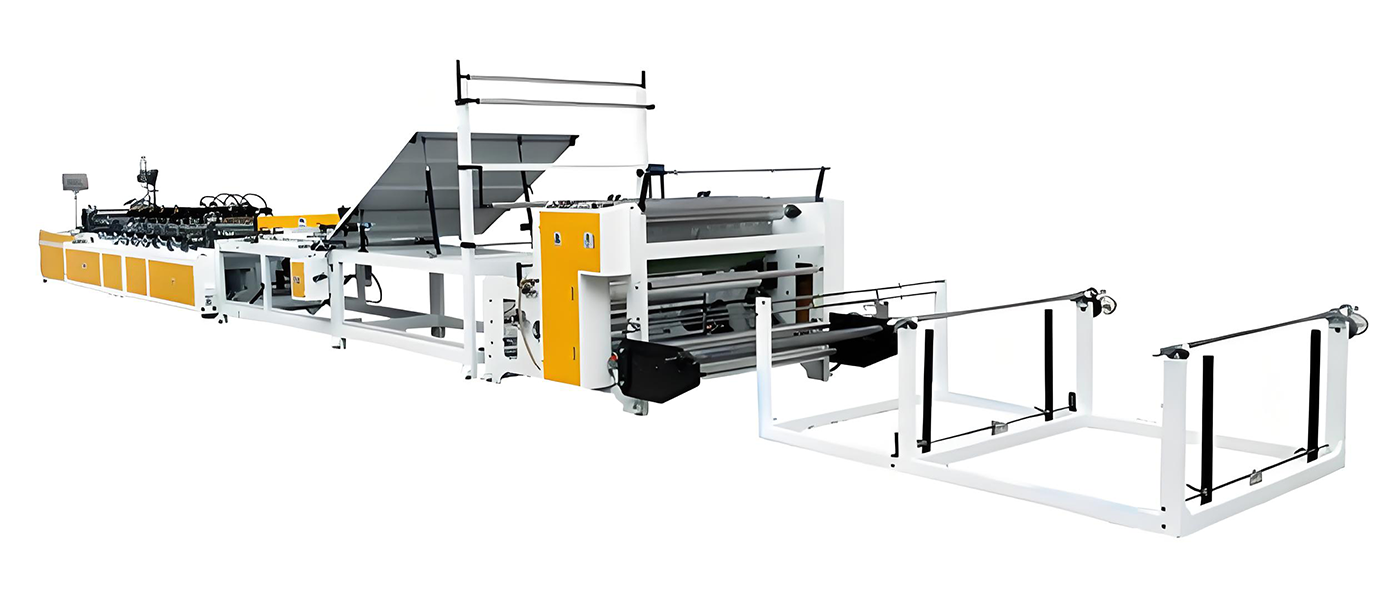

As a professional bubble foil guested bag making machine, it specializes in processing aluminum laminated bubble film (outer aluminum foil + inner bubble film) into guested (gusseted) mailers. The machine integrates key workflows: first, it feeds the aluminum laminated bubble film stably, with automatic paper discharge correction to avoid material deviation; then, it uses the built-in folding function to form gussets on both sides of the film (enhancing bag capacity); next, the gluing function ensures tight bonding of folded parts, and the sealing unit forms a secure structure.

Equipped with a PLC touch display and programmable computer program, it supports arbitrary fixed length setting and color code tracking positioning for precise mailer sizing. Automatic counting allows setting the number of bags to trigger automatic machine stop, simplifying batch production. With a production speed of 20-50 pcs/min, it balances efficiency and quality, ensuring each aluminum foil bubble guested mailer has consistent structure and reliable insulation.

Features

- Specialized aluminum foil + bubble film production: Focuses on making mailers with outer aluminum foil and inner bubble film—combining insulation of aluminum foil and cushioning of bubble film.

- PLC touch control: Adopts PLC touch display and programmable computer program for intuitive operation, easy parameter adjustment.

- Automatic counting & fixed length: Supports automatic counting (stops at set bag number) and arbitrary fixed length setting with color code tracking positioning—ensuring precise mailer size.

- Automatic correction & integrated functions: Has automatic paper discharge correction to prevent deviation; comes with folding and gluing functions for one-stop guested bag production.

- Stable & reliable: Features stable performance and safe operation, suitable for long-term continuous production of aluminum laminated bubble film insulation guested bags.

- Moderate high efficiency: Production speed of 20-50 pcs/min, meeting medium-to-large batch production needs while ensuring mailer quality.