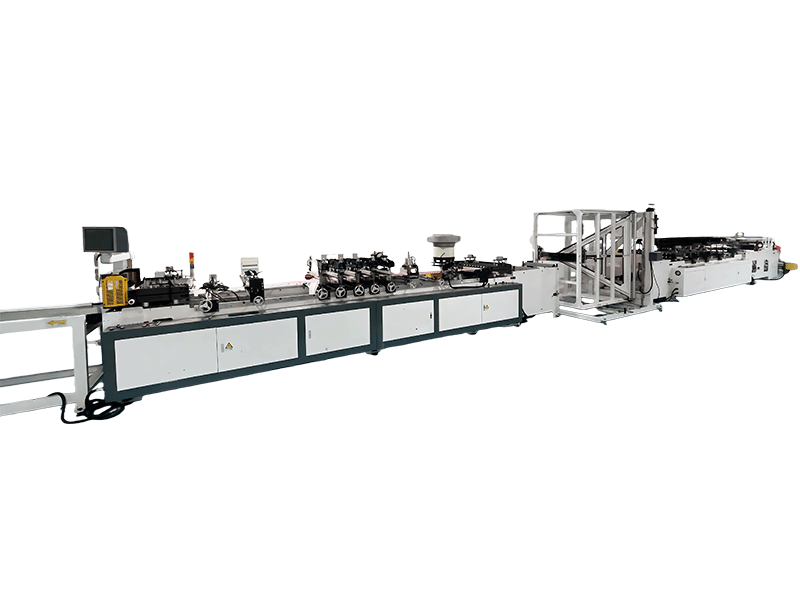

Description

As a professional zipper mailer production equipment, it follows a streamlined "bubble film unwinding → zipper attachment → folding forming → edge sealing → cutting" workflow. First, the unwinding unit feeds air bubble film (inner bubble layer for cushioning, outer film for protection) stably, with tension control to avoid deformation. The core step is the zipper attachment unit: it automatically aligns and bonds a plastic zipper strip to the top edge of the bubble film—ensuring the zipper is firmly fixed and aligned with the mailer opening.

Next, the folding unit shapes the bubble film (with attached zipper) into a mailer structure; the edge-sealing unit seals the two sides and bottom to form a closed bag, leaving only the zipper opening for use. Finally, the cutting unit trims the continuous material into individual mailers of set sizes. The machine uses precise positioning technology to ensure the zipper matches the mailer opening perfectly, enabling smooth opening and closing—users can seal/unseal the mailer repeatedly without damaging the structure.

Feature

- Integrated zipper function: Adds a reusable plastic zipper to air bubble mailers—enables convenient, repeatable sealing (no tape needed), enhancing user experience.

- Precise zipper attachment: Equipped with automatic zipper alignment and bonding technology, ensuring the zipper is firmly fixed and aligned with the mailer opening for smooth use.

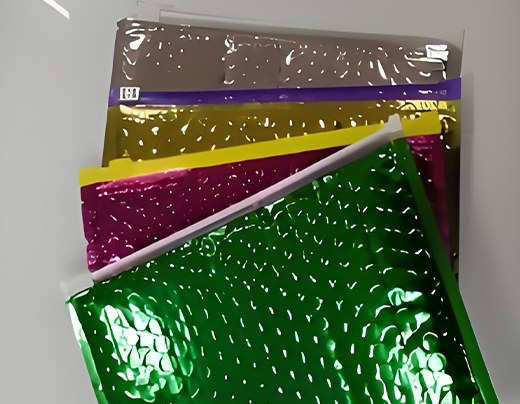

- Bubble cushioning + zipper convenience: Combines the shock-absorbing property of bubble film (protects fragile items) with the reusable sealing of zippers—balances protection and practicality.

- Efficient production: Integrates unwinding, zipper attachment, forming, sealing, and cutting into one line, with a production speed of 40-80 mailers per minute—meeting mass packaging needs.

- Flexible size customization: Supports adjusting mailer length, width, and zipper size via the control panel—adapting to small items (cosmetics, accessories) and medium goods (tablets, small electronics).

- Stable operation: Equipped with microcomputer control and automatic deviation correction (for both bubble film and zipper strip), ensuring consistent mailer size and zipper bonding quality.