Description

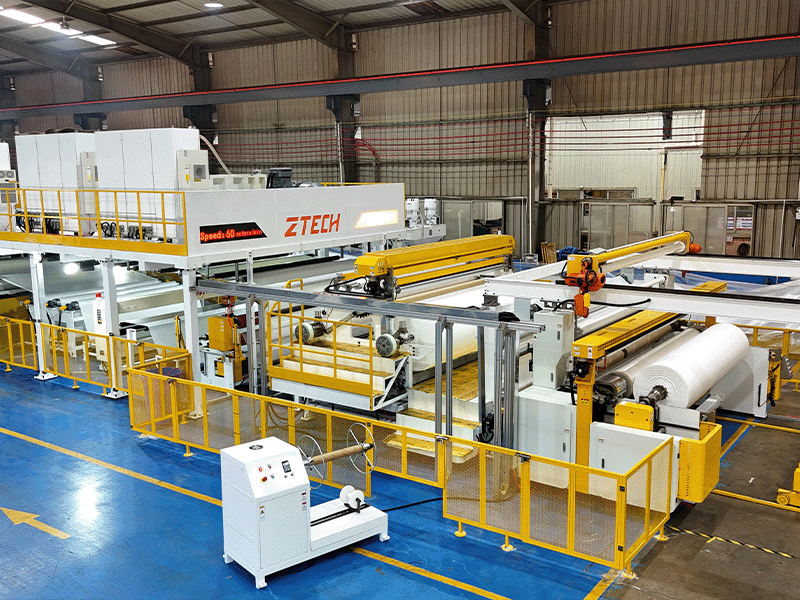

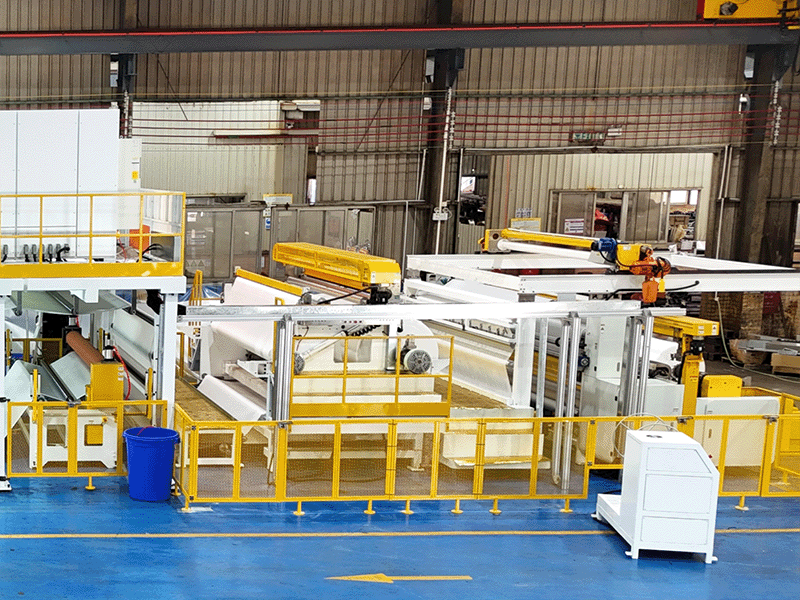

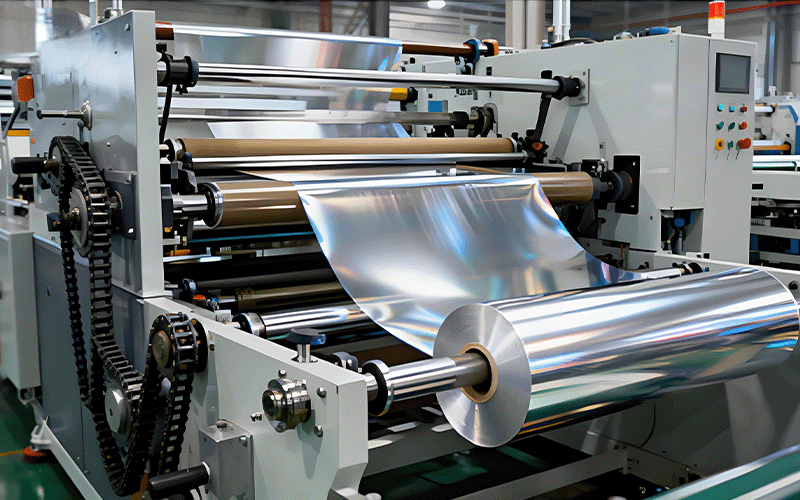

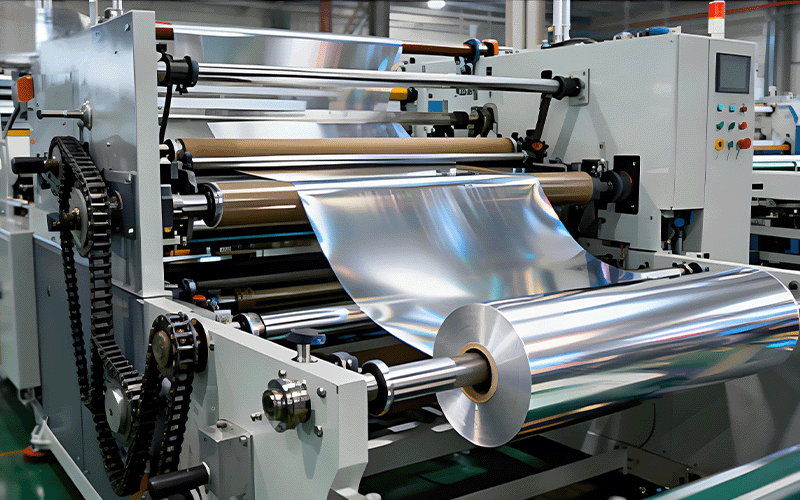

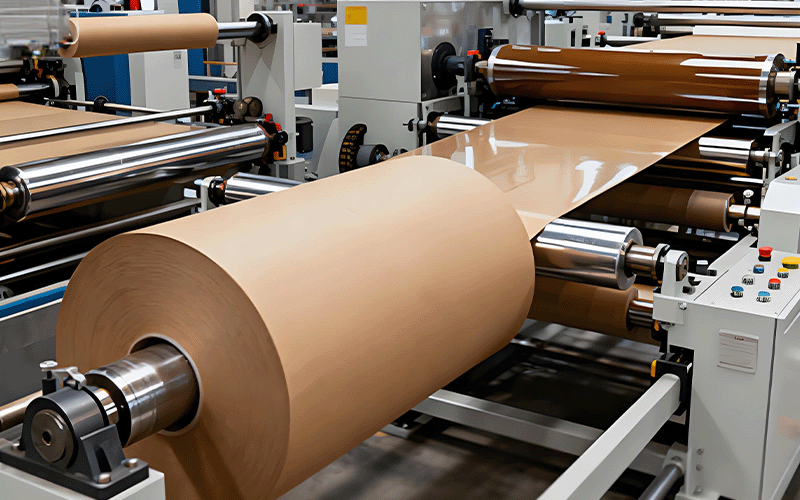

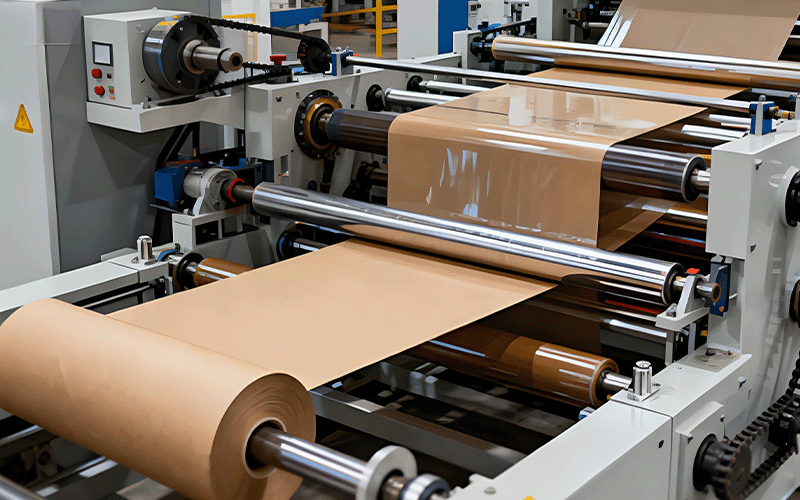

The machine adopts an integrated production process. First, raw materials (PE granules) are fed into a high-performance extruder, where they are fully melted and plasticized. The molten PE is then extruded through a die head into a uniform film. Simultaneously, the aluminum foil or kraft paper substrate is unwound and guided to the lamination unit. In the lamination unit, the extruded PE film is precisely coated onto the substrate under controlled temperature and pressure, forming a composite material. After lamination, the composite material undergoes cooling, thickness measurement, edge trimming, and winding processes. The entire production line is equipped with intelligent control systems to monitor and adjust key parameters such as extrusion temperature, lamination pressure, and speed in real-time, ensuring consistent product quality.

Feature

- Integrated Production Process: Combines cast film extrusion and lamination into one continuous process, enabling one-time completion of substrate and PE film lamination, which significantly improves production efficiency.

- Precise Coating Control: Equipped with a high-precision die head and lamination unit, it can uniformly coat PE onto aluminum foil or kraft paper with accurate thickness control, ensuring consistent coating quality.

- Intelligent Control System: Utilizes a PLC-based control system and touchscreen HMI for real-time monitoring and adjustment of extrusion temperature, lamination pressure, speed, and other parameters, achieving precise control over the production process.

- Versatile Substrate Compatibility: Can work with various substrates such as aluminum foil and kraft paper, meeting different production needs for composite materials.

- High Production Efficiency: Operates at high speeds while maintaining stable production, capable of meeting large-scale production requirements for composite materials.

- Reliable Component Configuration: Incorporates high-quality extruder components, bearings, and control devices, ensuring stable operation, low failure rates, and a long service life of the equipment.

Technical Parameters

| Model | Dimension (m) | Power (kw) | Max Processing Width (mm) | Processing Speed (m/min) |

| ZT-PCF1600 | 18*7*3 | 50 | 1600 | 50-100 |

| ZT-PCF1800 | 18*8*3 | 65 | 1800 | 50-100 |

| ZT-PCF2000 | 18*9*3 | 80 | 2000 | 50-100 |

| ZT-PCF2200 | 18*10*3 | 95 | 2200 | 50-100 |