Description

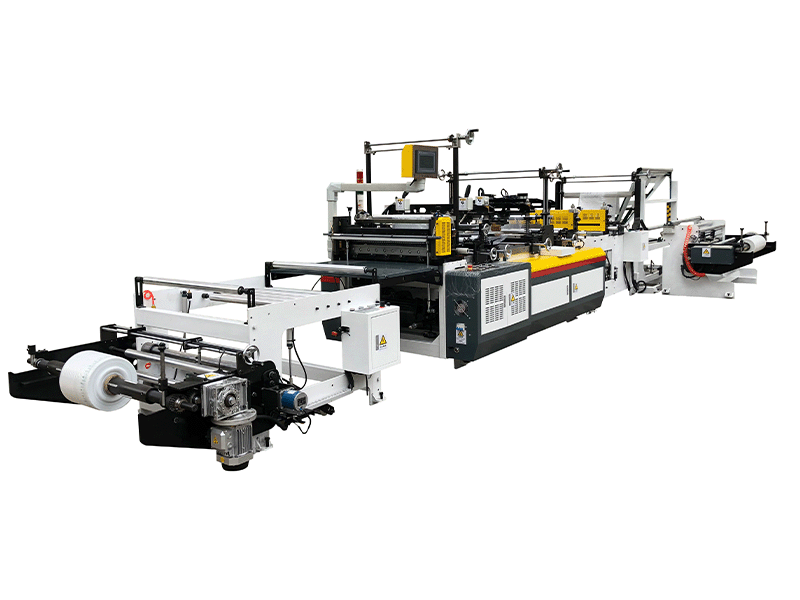

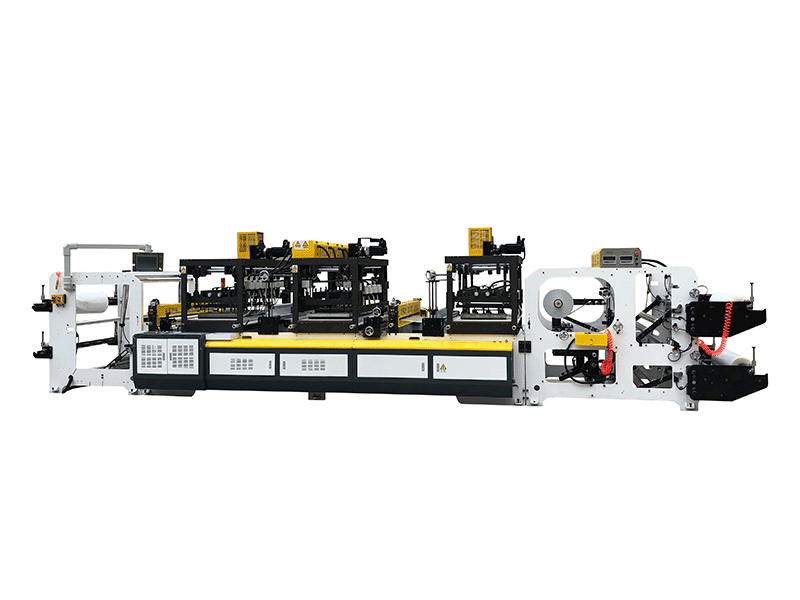

As a professional air column bag production equipment, this machine follows a streamlined "film unwinding → air column forming → heat sealing → cutting" workflow. It uses dedicated air column film (multi-layer co-extruded film) as raw material: first, the unwinding unit feeds the film stably; then, the forming unit presses the film into evenly spaced air column channels via precision rollers.

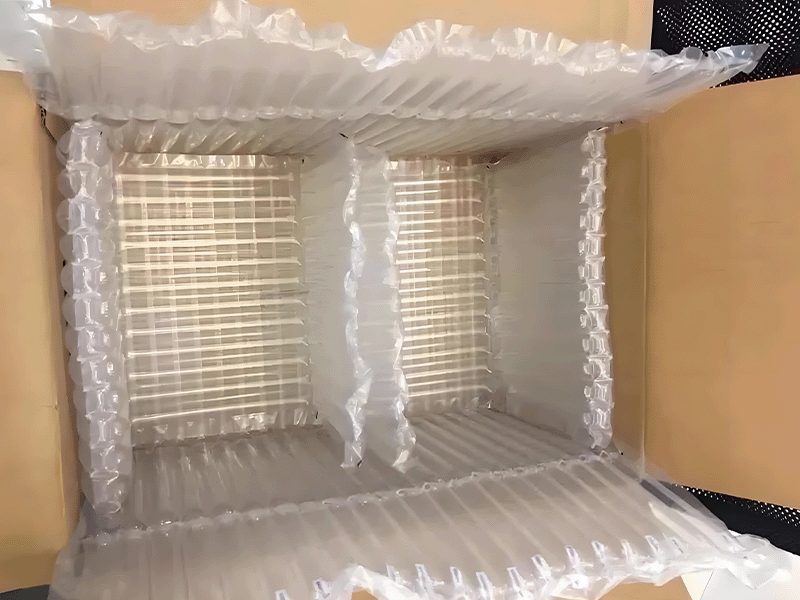

Next, the heat-sealing unit seals the edges of the air column channels and the bag’s perimeter, leaving an air inlet for later inflation. Finally, the cutting unit trims the continuous air column film into individual bags of set sizes (e.g., small for smartphones, large for wine bottles). The entire process ensures each air column is airtight—after inflation, the columns form a flexible buffer layer that absorbs impact and prevents goods from shaking.

Features

- Professional air column forming: Creates uniform, airtight air column channels, ensuring the bag has strong buffer performance after inflation.

- High-sealing precision: Uses heat-sealing technology with temperature-adjustable heating heads, ensuring tight seals for air columns and bag edges—no air leakage during use.

- Flexible size customization: Supports adjusting bag length, width, and number of air columns to match different goods (e.g., thin bags for cosmetics, wide bags for liquor).

- Stable operation: Equipped with microcomputer control and tension adjustment, avoiding film deformation during processing and ensuring consistent bag quality.

- Efficient production: Integrates multiple processes into one line, with a production speed of 30-60 bags per minute—meeting mass packaging needs for e-commerce and logistics.

- Film compatibility: Adapts to different thicknesses of air column film (usually 0.08-0.15mm), ensuring stable production for various buffer strength requirements.