Description

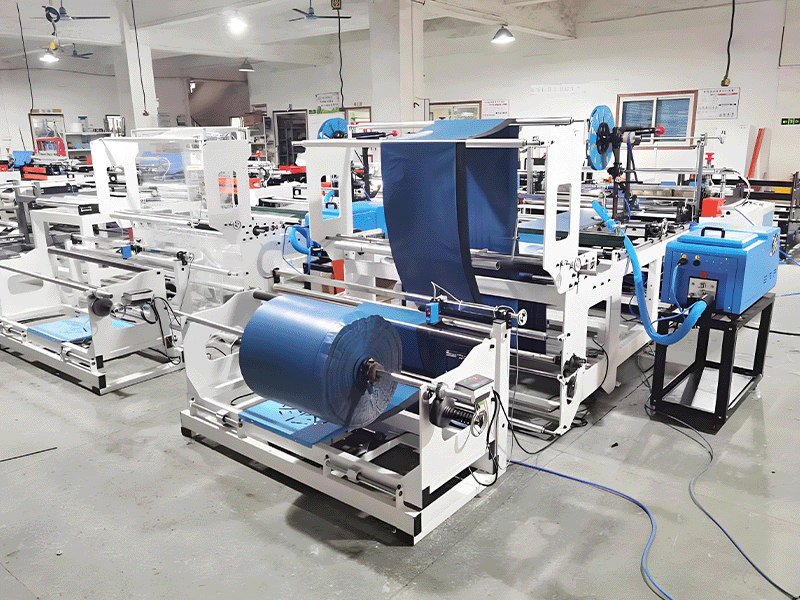

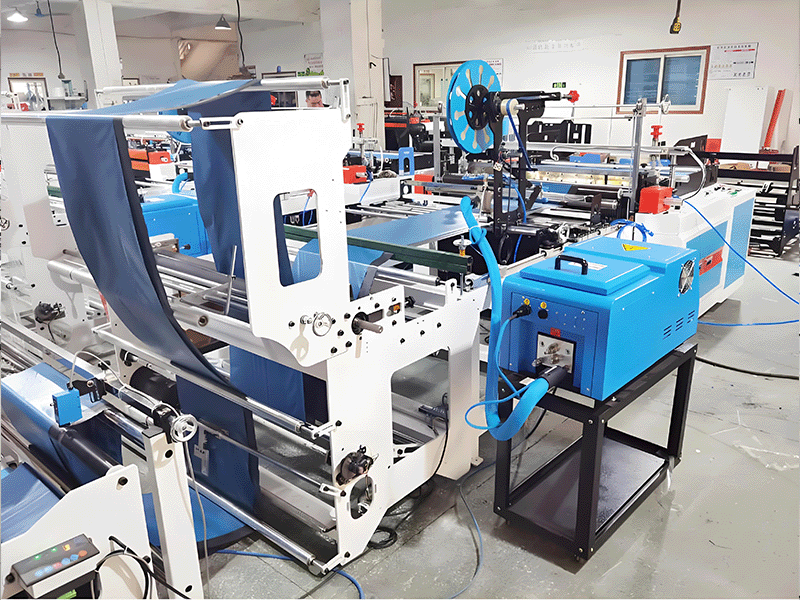

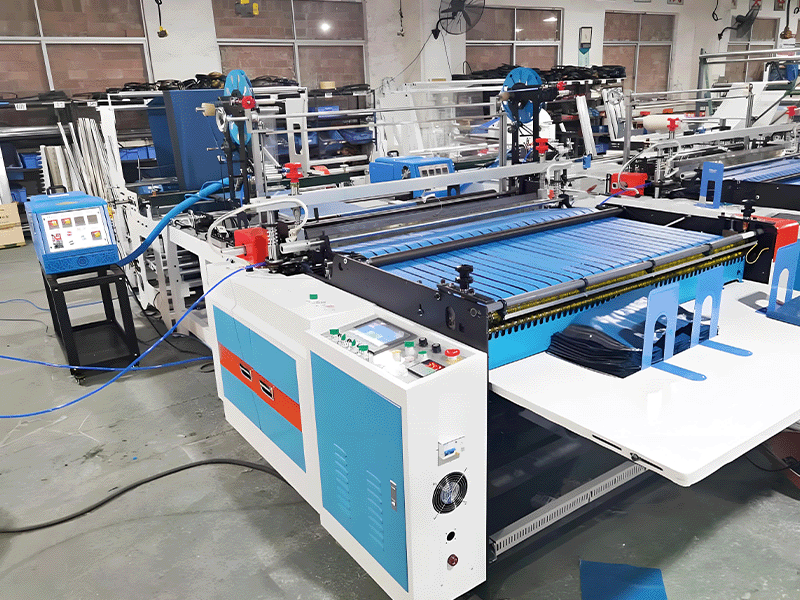

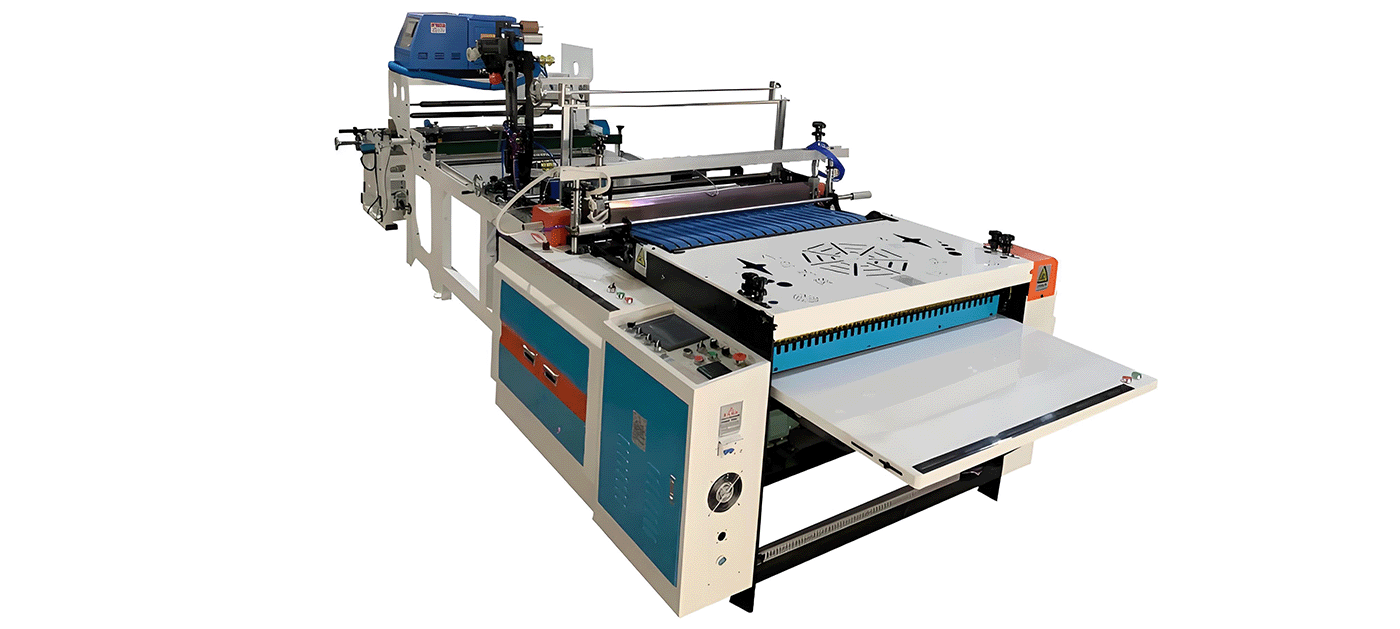

As a core equipment for courier bag production, this machine follows a streamlined "material unwinding → film bonding (if needed) → edge sealing → bottom sealing → cutting" workflow. It mainly uses waterproof films (such as PE film, CPP film, or laminated films with anti-scratch layers) as raw materials: first, the unwinding unit feeds the film stably, with tension control to avoid film deformation.

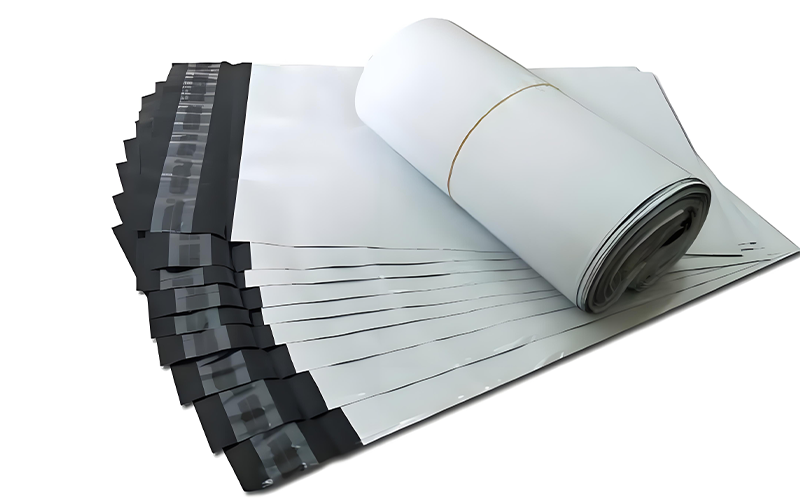

For courier bags with composite structures (e.g., outer waterproof layer + inner buffer layer), the machine’s bonding unit first laminates multiple films; then, the edge-sealing unit uses heat-sealing technology to seal both sides of the film, and the bottom-sealing unit forms a closed bag bottom (supporting flat or gusseted bottoms for larger capacity). Finally, the cutting unit trims the continuous film into individual courier bags of set sizes (e.g., 15×25cm for small parcels, 30×40cm for medium packages). The machine can also be equipped with optional functions like self-adhesive tape pasting (for easy sealing) or label printing (for waybill attachment).

Features

- Waterproof material compatibility: Specializes in processing PE, CPP, and laminated waterproof films—ensuring courier bags resist moisture during rainy or humid transit.

- Efficient integrated production: Combines unwinding, bonding, sealing, and cutting into one line, with a production speed of 80-120 bags per minute—meeting mass-order needs of e-commerce and logistics companies.

- Flexible size & structure customization: Supports adjusting courier bag length, width, and bottom type (flat/gusseted); optional self-adhesive tape or label printing functions adapt to different logistics requirements.

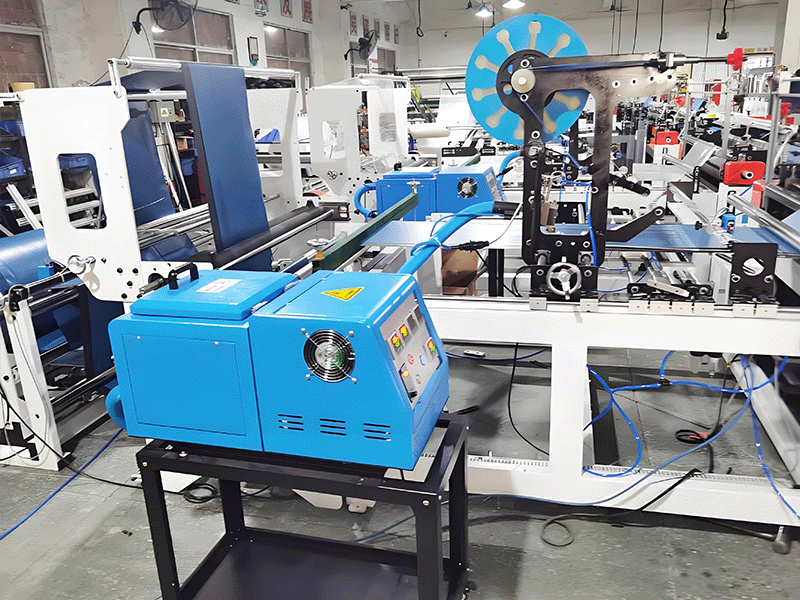

- Strong sealing performance: Uses temperature-adjustable heat-sealing heads, ensuring tight edge and bottom seals—preventing parcel leakage or damage from external impacts.

- Stable operation: Equipped with microcomputer control and automatic deviation correction, avoiding film offset during processing and ensuring consistent bag size and sealing quality.

- User-friendly design: Simple touch-panel operation for parameter setting (size, speed, temperature); easy maintenance of core components (sealing heads, cutters) to reduce downtime.