Description

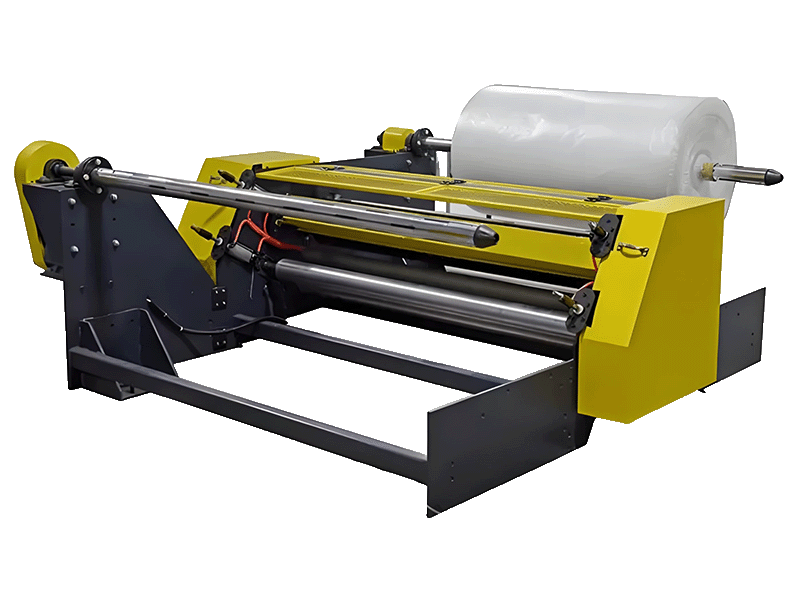

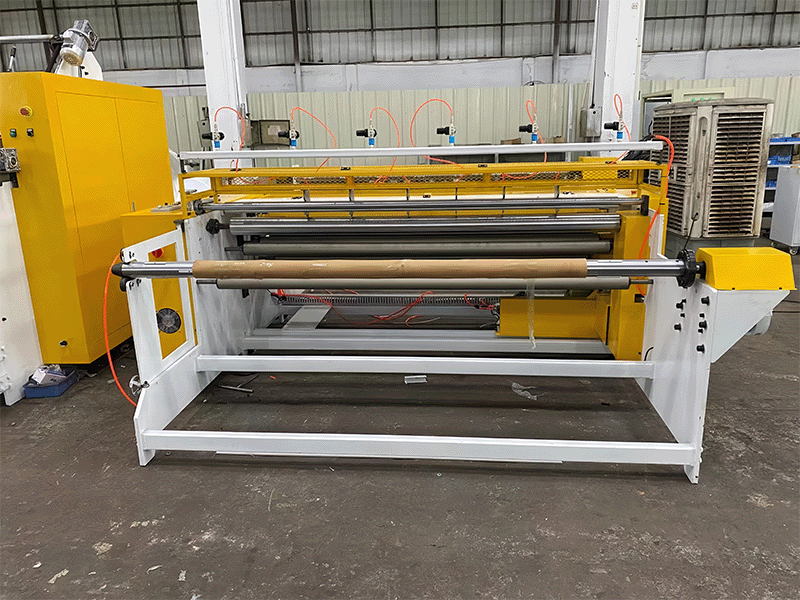

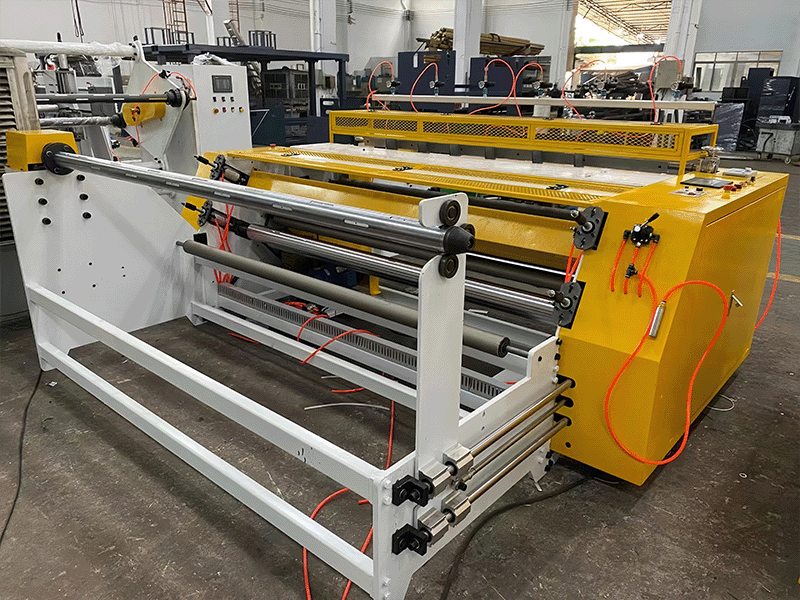

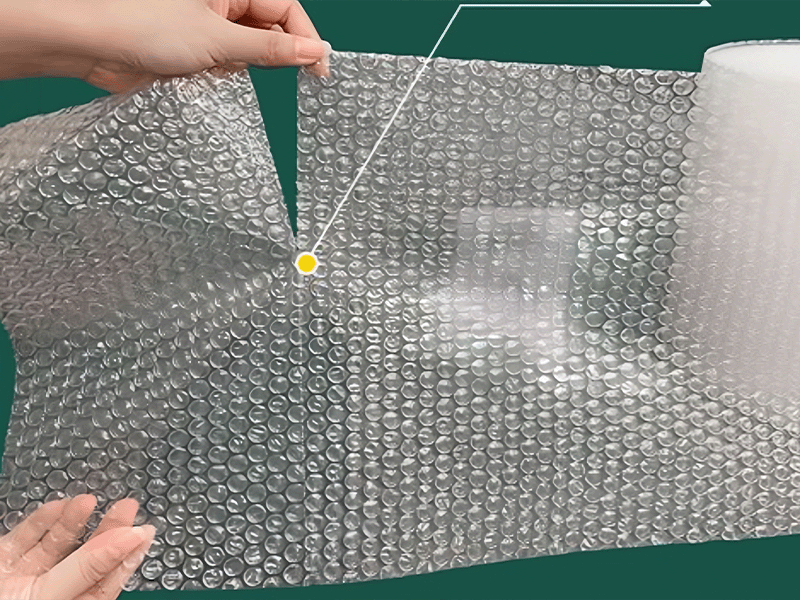

As a professional EPE foam and bubble film processing equipment, this perforator adopts an integrated "feeding-perforating-rewinding" workflow, with standard configuration including one set of feeding rack, one set of perforation unit, one set of winder, and a PLC control system. What sets it apart is the adoption of servo motors and matching drivers: during operation, the servo system accurately controls the feeding speed and stop position of EPE foam/bubble film, ensuring the pre-cut length matches the set value without deviation.

When in use, EPE foam or bubble film is placed on the feeding rack (which maintains stable tension to avoid material deformation). The servo-driven feeding mechanism conveys the film to the perforation unit—equipped with German-imported blades—to create clean, burr-free pre-cut lines. After perforation, the servo-controlled winder automatically rolls the processed film into neat rolls. The entire process requires no manual cutting, solving the problem of inconsistent lengths from manual operation, while the servo system’s high precision meets strict size requirements for packaging materials.

Features

- Servo-driven precise pre-cutting: Adopts servo motors and drivers for control, ensuring pre-cut lengths (e.g., 2m for furniture packaging) are highly accurate, with no deviation in size.

- Pre-defined length customization: Supports setting custom pre-cut lengths via PLC control, adapting to diverse needs (from small 50cm rolls for small goods to 2m+ rolls for furniture).

- Standard integrated configuration: Comes with feeding rack, perforation unit, and winder as standard—realizing one-stop "feeding-perforating-rewinding" without additional equipment.

- Durable nylon brush roller: Brush roller is made of nylon—softer and more durable than competitors’ plastic rollers, avoiding scratches on EPE foam/bubble film surfaces.

- Imported German blades: All blades are imported from Germany, ensuring long-lasting sharpness and durability for clean, burr-free pre-cut lines.

- Safe operation design: Equipped with protective barriers; when barriers are opened, the cylinder stops automatically to prevent equipment damage and ensure operator safety.

Technical Parameters

| Model | ZT160-PR |

| Max width | 1600mm |

| Minimum distance | 150mm |

| Speed | 30-50M/min |

| Tolerance | 1-5mm |

| weight | 800kg |

| power | 8kw |