Description

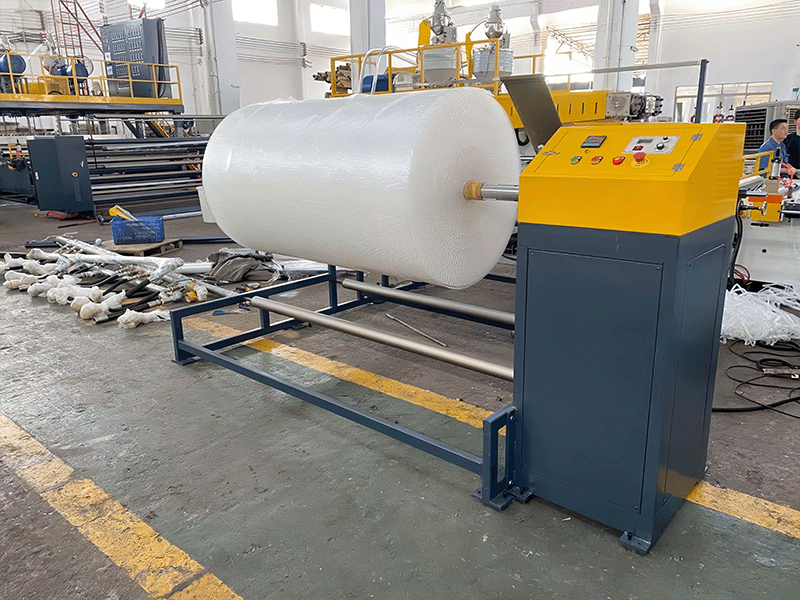

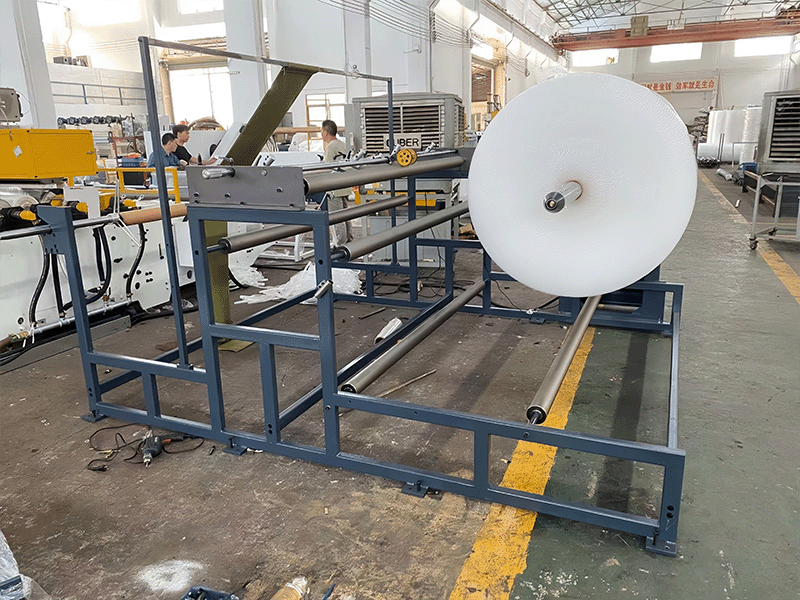

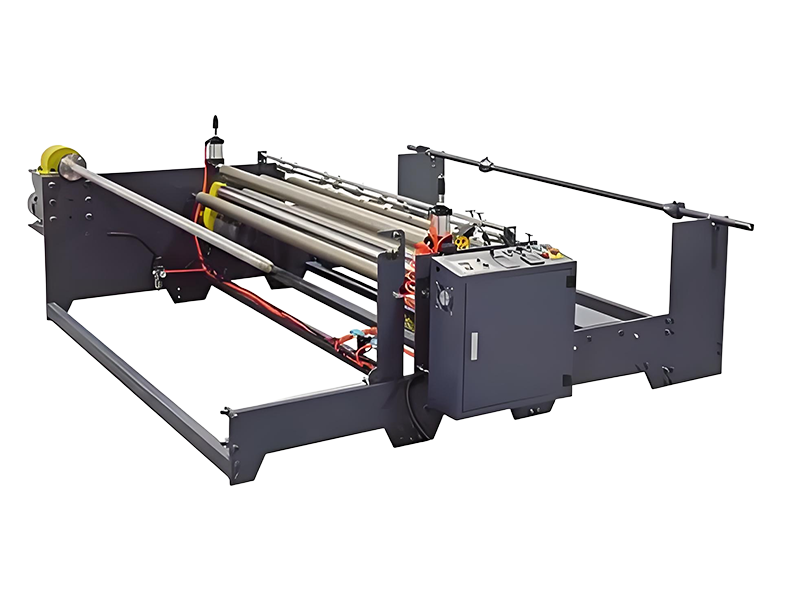

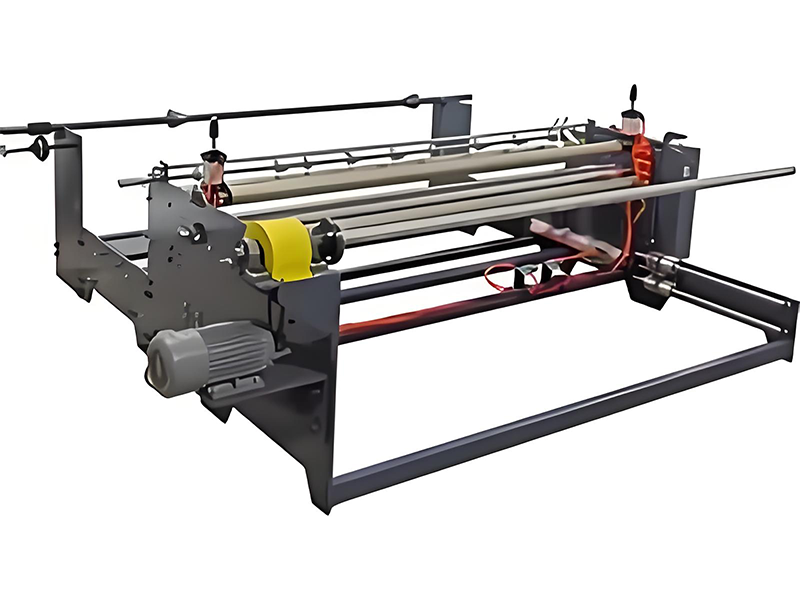

As a professional EPE foam and bubble film processing equipment, this slitter machine adopts an integrated "unwinding-slitting-rewinding/cutting" workflow. The standard configuration includes an unwinding unit (for stable feeding of EPE foam/bubble film rolls), a slitting unit (for width adjustment), a length control unit, and a collecting unit (rewinder or cutter).

When in operation, first set the target width (e.g., 30cm, 50cm) and length (e.g., 1m, 2m) via the control panel. The unwinding unit then conveys the EPE foam or bubble film roll to the slitting unit: multiple adjustable blades in the unit cut the material into strips of the set width. After width slitting, the material enters the length control unit—equipped with a precision sensor to detect and cut the strips into the pre-set length. Finally, the processed sheets (or rolls, if using the rewinder) are collected uniformly. The entire process avoids manual measurement and cutting, ensuring consistent size of each piece of EPE foam or bubble film.

Features

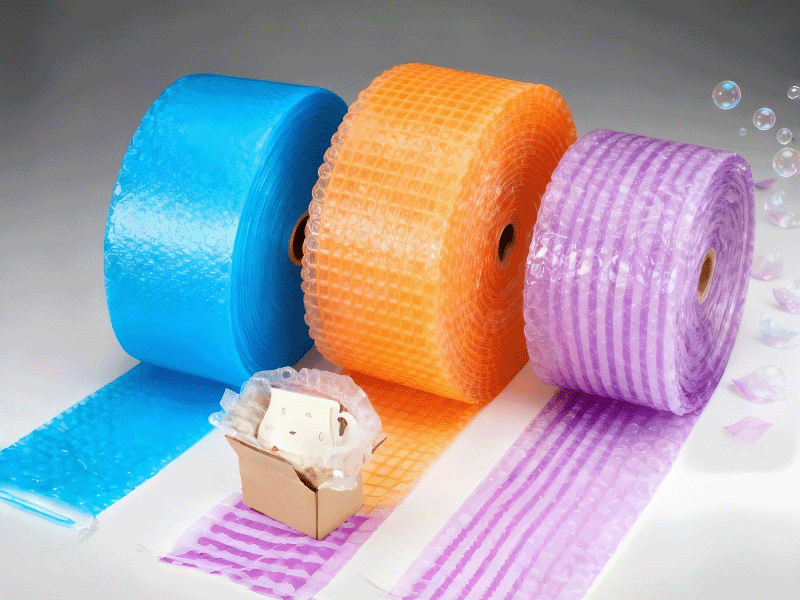

- Dual-dimension customization: Supports setting both width and length parameters, enabling cutting of EPE foam and bubble film into diverse sizes to match different packaging needs.

- Precise slitting: Adopts high-precision blade adjustment and length-sensing technology, ensuring uniform width and length of processed materials, with no burrs on edges.

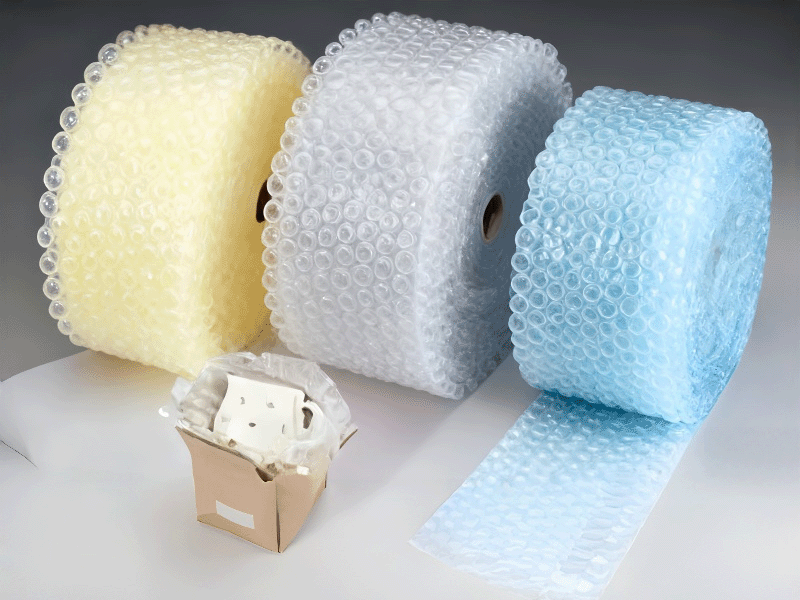

- Wide material adaptability: Specialized in processing EPE foam and bubble film of different thicknesses (from thin bubble film to thick EPE foam), with adjustable blade pressure to avoid material deformation.

- Efficient workflow: Integrates unwinding, slitting, length cutting and collecting into one line, reducing manual steps and improving processing efficiency by over 50% compared to manual operation.

- User-friendly control: Features an intuitive touch panel for parameter setting, with clear digital display of width, length and production quantity—lowering the operation threshold.

- Stable operation: Equipped with a tension control system in the unwinding unit, preventing material deviation during slitting and ensuring smooth processing.

Technical Parameters

| Model | ZT160-LM |

| Max width | 1600mm |

| Speed | 30-50M/min |

| Tolerance | +-0.5mm |

| weight | 400kg |

| power | 5kw |