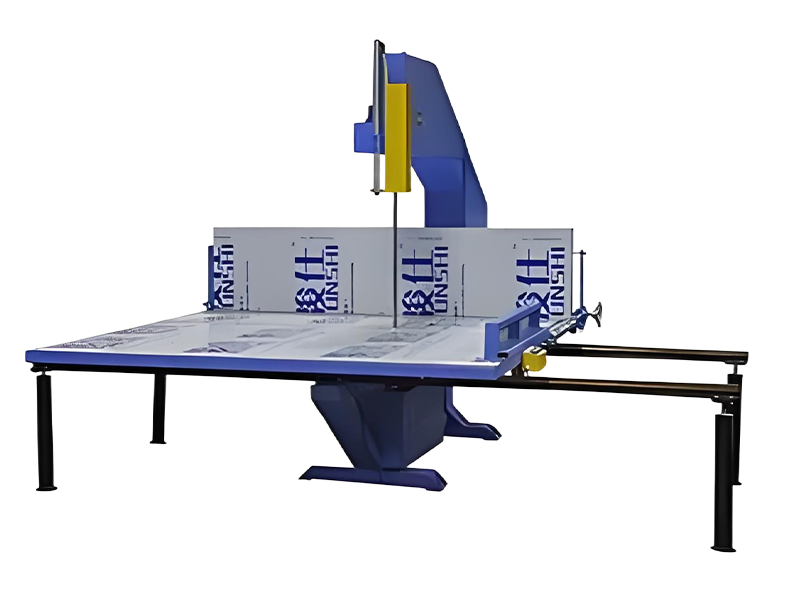

Description

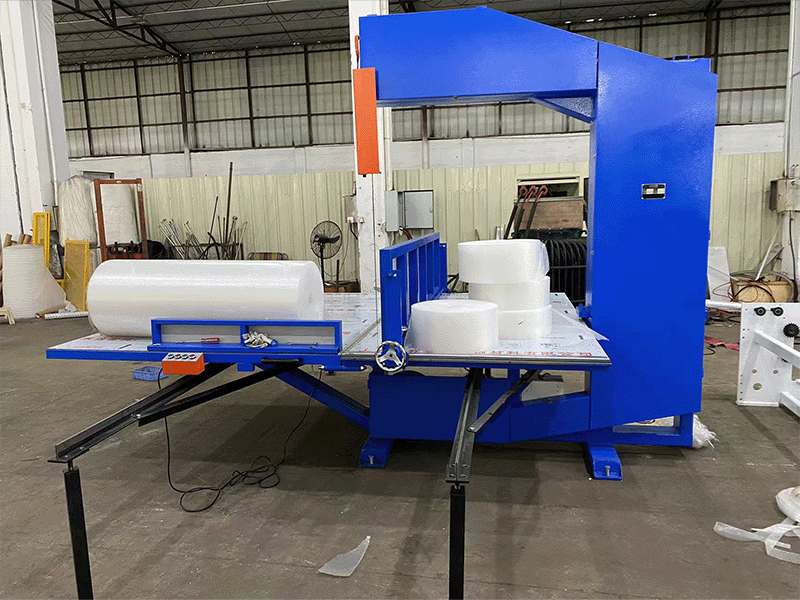

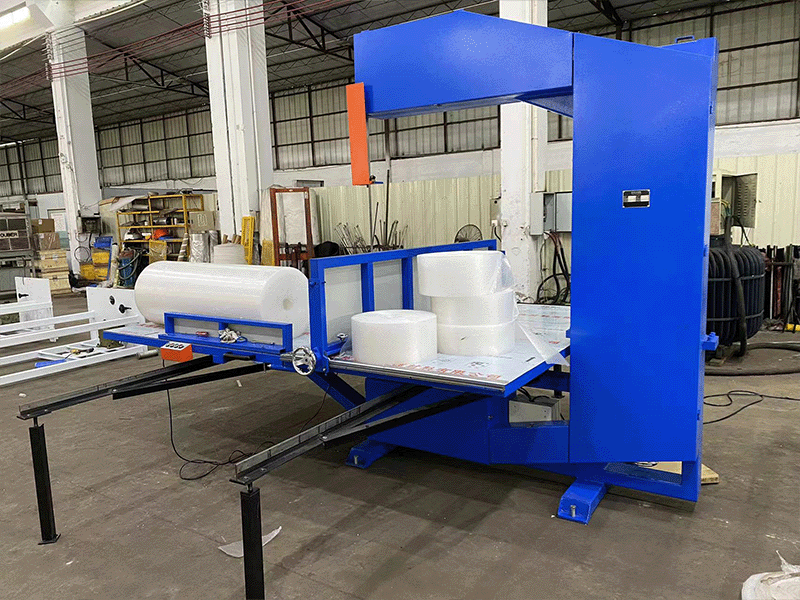

As a straightforward cutting tool for bubble film and EPE foam rolls, this machine features a single saw blade as its core component. It works by placing the roll (whether with a paper core or not) on the machine, adjusting the desired width, and then using the saw blade to slice through the roll cleanly.

The design focuses on simplicity: no complex setups, just basic adjustments to set the width. It handles both bubble film rolls (including those with paper cores) and EPE foam rolls, ensuring even cuts regardless of the material’s flexibility or whether a core is present. The saw blade is sharp enough to slice through rolls smoothly, resulting in neat edges without damaging the material.

Features

- Simple structure: Uses a single saw blade for cutting, with no complicated components—easy to understand and operate.

- Versatile for roll types: Cuts both bubble film rolls and EPE foam rolls, whether they have a paper core or are coreless.

- Width customization: Allows adjustment to cut rolls into different widths, meeting various packaging size needs.

- Easy to use: Basic controls for setting width and starting the saw, requiring minimal training for operation.

- Clean cutting: Sharp saw blade ensures even, neat edges on both bubble film and EPE foam rolls.

Technical Parameters

| Model | ZT160-SM |

| Max width | 1600mm |

| Max Roll diameter | 1000mm |

| Tolerance | +-0.5mm |

| weight | 600kg |

| power | 10kw |