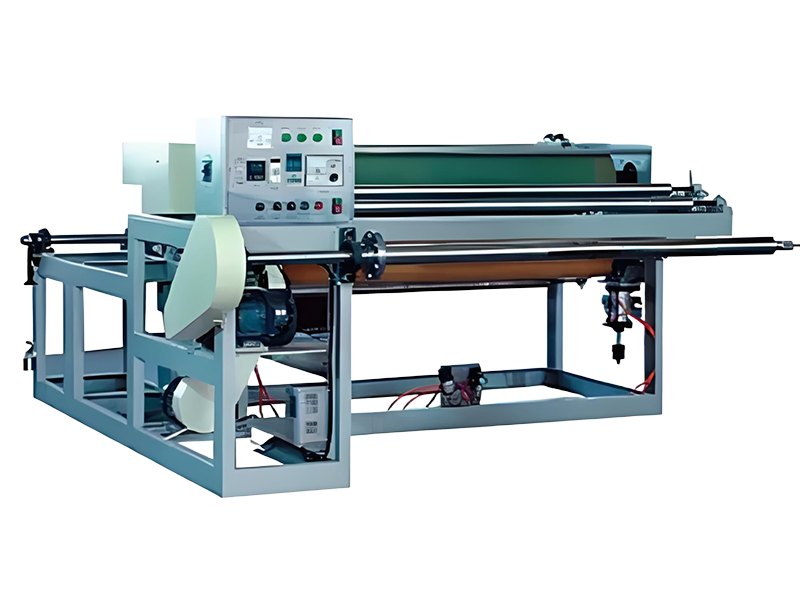

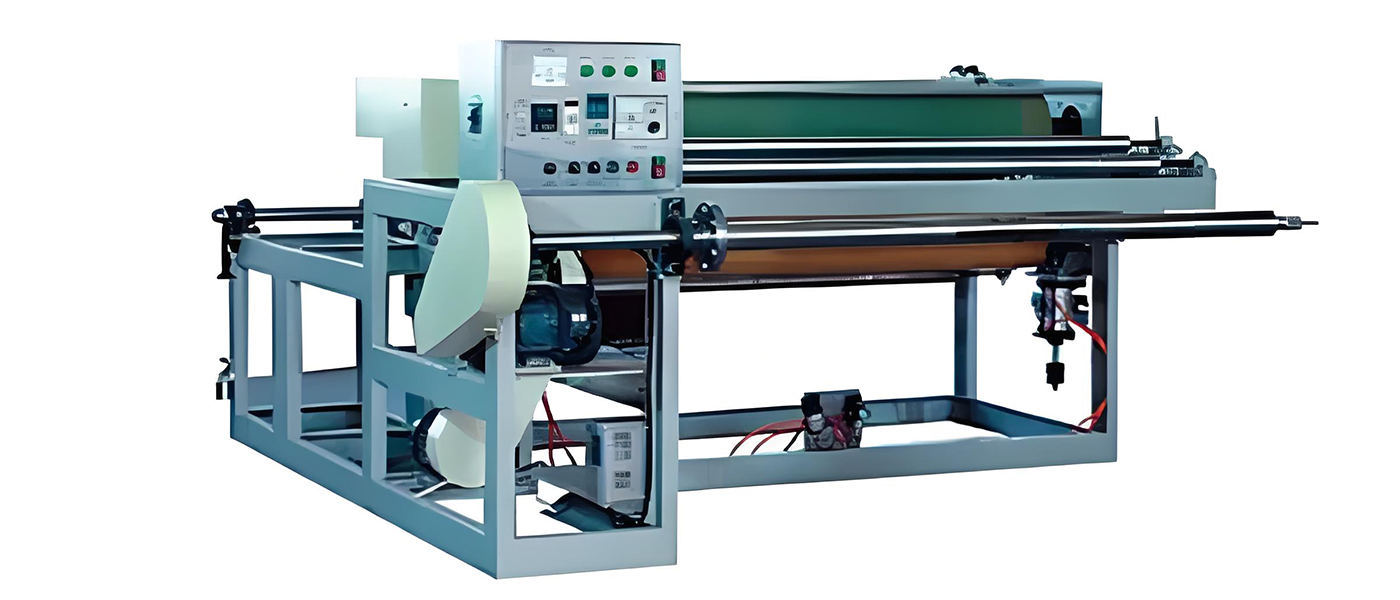

Description

This machine adopts a streamlined process to achieve precise lamination. EPE foam sheets are first fed into the machine. Simultaneously, the PE film or aluminum foil roll is unwound and guided to the coating unit. In this unit, under controlled temperature and pressure, the PE film or aluminum foil is uniformly and firmly laminated onto the surface of the EPE foam sheet. The machine is equipped with adjustable tension control systems for both the EPE foam and the laminating material (PE film/aluminum foil) to ensure smooth feeding and precise alignment during the lamination process. After lamination, the composite material exits the machine, ready for further processing or direct use.

Feature

- Efficient Lamination: Specifically designed for efficiently laminating one layer of PE film or aluminum foil onto EPE foam sheets, enhancing production speed and efficiency.

- Dual Material Compatibility: Capable of laminating both PE film and aluminum foil onto EPE foam, providing flexibility to meet different product performance requirements (such as waterproofing, heat reflection, etc.).

- Precise Alignment & Bonding: Equipped with tension control and alignment systems to ensure accurate positioning and firm bonding between the EPE foam and the laminating material.

- Adjustable Parameters: Allows for adjustment of lamination temperature and pressure, enabling optimal bonding quality for different thicknesses and types of EPE foam, PE film, and aluminum foil.

- User-friendly Operation: Features an intuitive control panel and simple feeding mechanism, making it easy for operators to set up and operate the machine.

- Reliable Performance: Incorporates high-quality components and a robust structure, ensuring stable operation and long service life, even in continuous production environments.

Technical Parameters

| Model | ZT-1400C | ZT-1750C | ZT-2050C | ZT-2250C |

| Film Thickness | 0.01-0.05 | 0.01-0.05 | 0.01-0.05 | 0.01-0.05 |

| Max.Width(mm) | 1300mm | 1600mm | 1900mm | 2100mm |

| Heating Style | Heating Pipe | |||

| Roller Net Size | 2*2mm | 2*2mm | 2*2mm | 2*2mm |

| Main Motor | 2.2kw | 2.2kw | 3.7kw | 3.7kw |

| Heating Pipe | D19*1450 | D19*1750 | D19*2050 | D19*2250 |

| Total Power | 18kw | 18kw | 22kw | 22kw |

| Speed | 0-30m/min | 0-30m/min | 0-30m/min | 0-30m/min |

| Dimension | 6000*2500*1800 | 6000*2800*1800 | 6000*3100*1800 | 6000*3300*1800 |

| Weight | 1.0T | 1.2T | 1.4T | 1.6T |