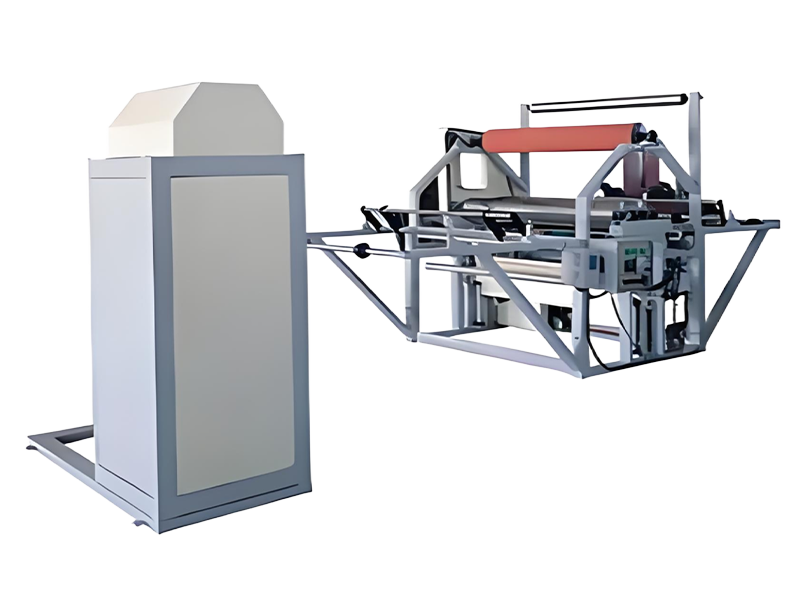

Description

The EPE Foam Laminator operates through a heating and pressing process. PE foam sheets are first fed into the machine, where they pass through a heating zone. The heating system, which can be gas or electricity powered, heats the surface of the foam sheets to a temperature that allows for effective bonding. Once heated, the sheets are then pressed together under controlled pressure to form a composite structure. The machine features adjustable heating temperatures and pressing pressures to ensure optimal bonding for different thicknesses and quantities of PE foam sheets. After lamination, the composite foam sheet exits the machine, ready for further processing or direct use.

Feature

- Multi-layer Lamination: Capable of laminating one or more layers of PE foam sheets together, enabling the creation of thicker and more versatile foam products.

- Dual Heating Options: Offers both gas heating and electricity heating methods, providing flexibility to suit different production environments and energy preferences.

- Thick Composite Capability: Can produce composite PE foam sheets with a maximum thickness of up to 100 mm, meeting the demand for thick foam applications.

- Adjustable Parameters: Allows for adjustment of heating temperature and pressing pressure, ensuring optimal bonding quality for various PE foam sheet specifications.

- Efficient Production: Designed for continuous operation, enhancing production efficiency and enabling large-scale manufacturing of laminated PE foam sheets.

- User-friendly Operation: Features intuitive controls and a simple feeding system, making it easy for operators to set up and run the laminating process.

Technical Parameters

| Model | ZT-1400L | ZT-1600L | ZT-2000L |

| Max.Thickness | 100mm | 100mm | 100mm |

| Max.Width(mm) | 1400mm | 1600mm | 2000mm |

| Unwinder Max. Diameter(mm) |

1000mm | 1000mm | 1000mm |

| Rewinder Max. Diameter (mm) |

1000mm | 1000mm | 1000mm |

| Speed | 5-40m/min | ||

| Heating Style | Gas Heating or Electricity Heating | ||

| Total Power | 3KW | ||

| Power | 380V, 50HZ, 3 PHASES | ||

| Dimension | 6000x2500x1800mm | 6000x2800x1800mm | 6000x3100x1800mm |

| Weight | 1T | 1.1T | 1.3T |