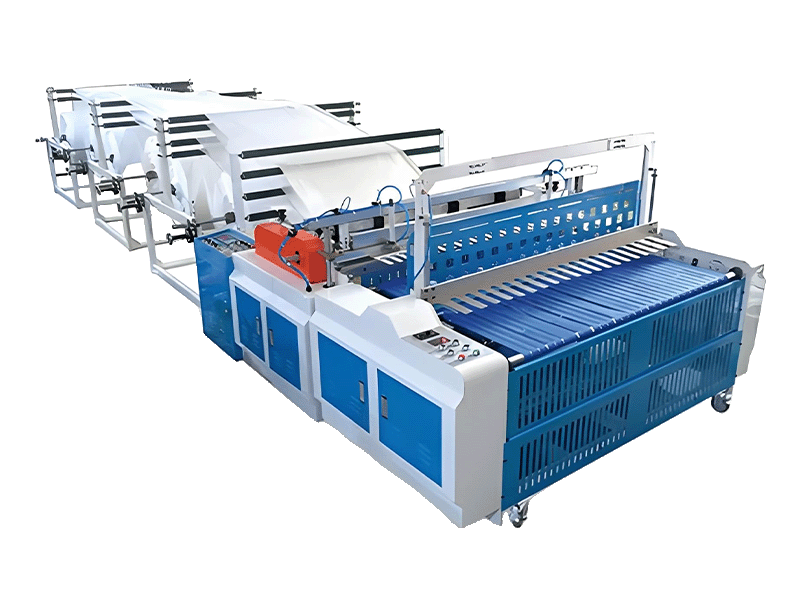

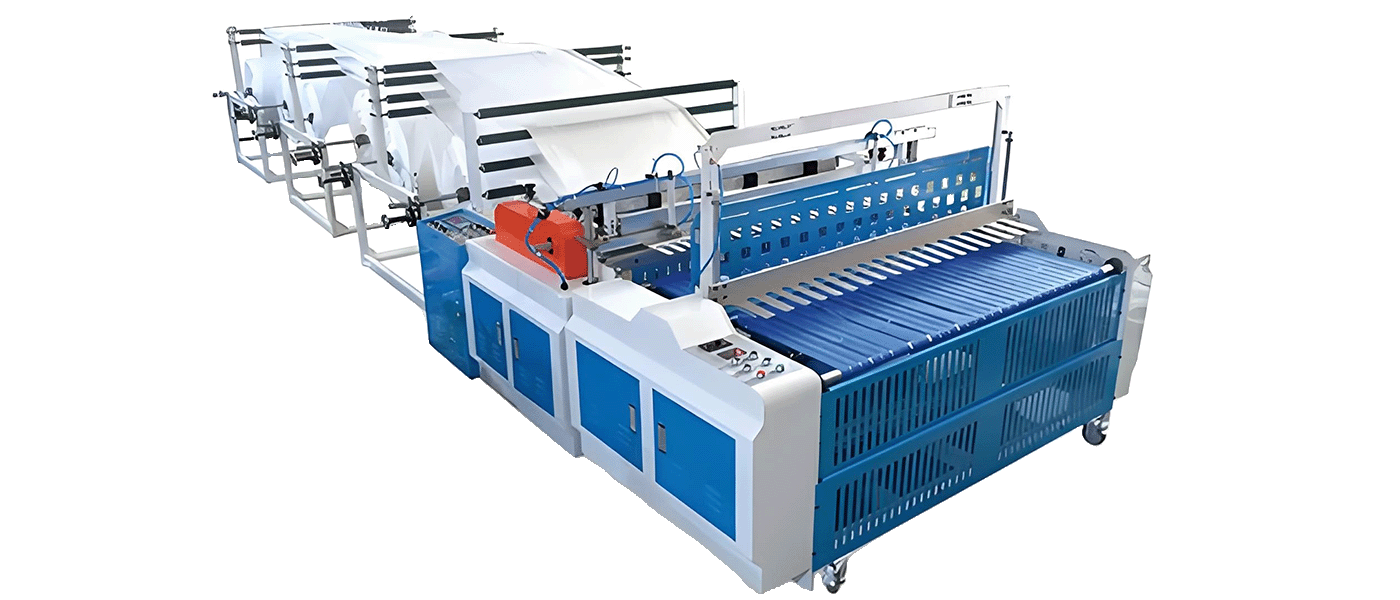

Description

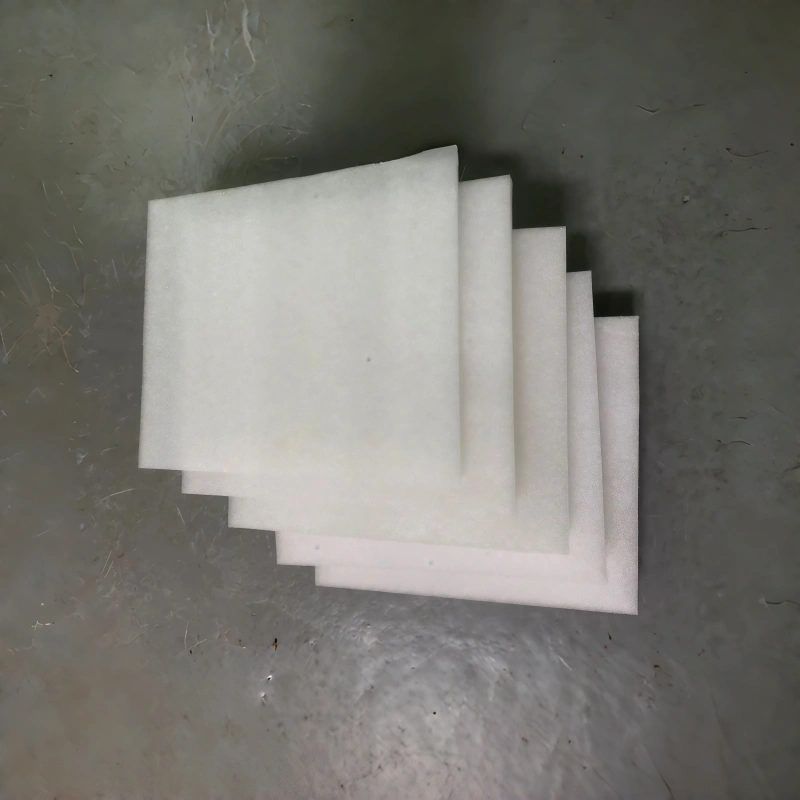

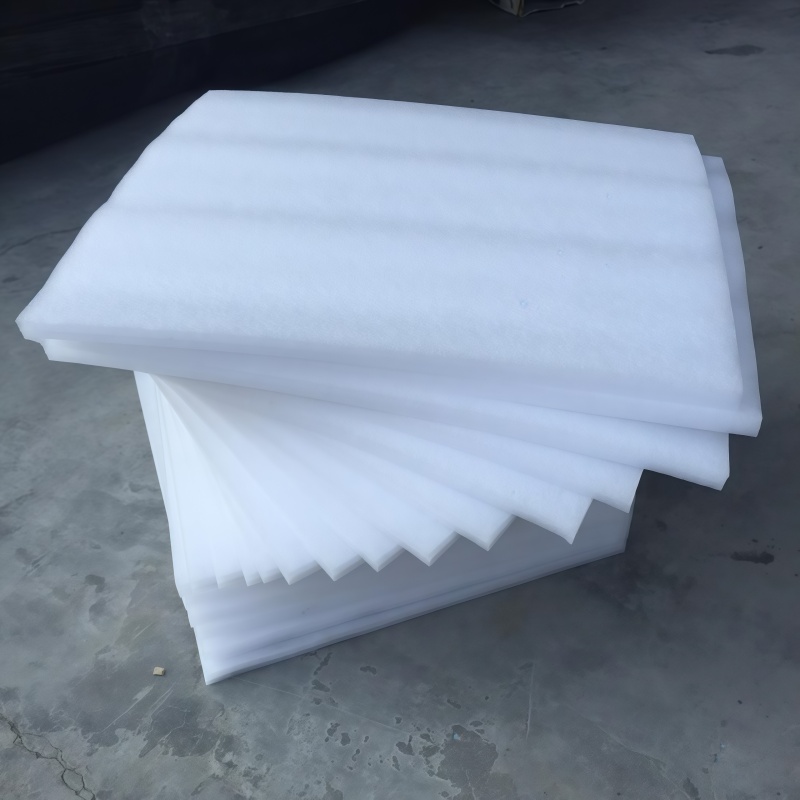

As a professional EPE foam and air bubble sheet cutting equipment, this machine adopts a multi-blade synchronous cutting design. When in operation, EPE foam or air bubble sheets are fed into the machine, and under the drive of a precise transmission system, multiple blades work together to cut the sheets into specified sizes. It supports simultaneous cutting of 5-6 sheets, which greatly improves cutting efficiency compared to single-sheet cutting.

Different models of this cutting machine are designed to adapt to EPE foam and air bubble sheets of different thicknesses. Whether it's thin air bubble sheets or thicker EPE foam, there is a corresponding model to ensure clean and accurate cuts without causing damage or deformation to the sheets. The cutting process is smooth, and the resulting sheet edges are neat, meeting the high standards required for packaging material processing.

Feature

- Multi-sheet simultaneous cutting: Capable of cutting 5-6 sheets of EPE foam or air bubble sheets at the same time, significantly enhancing cutting efficiency.

- Model diversity: Offers different models to match EPE foam and air bubble sheets of various thicknesses, ensuring optimal cutting performance for each thickness range.

- Precise cutting: Adopts advanced blade technology and precise transmission system, ensuring accurate and clean cuts with neat edges.

- Wide material compatibility: Specialized in processing EPE foam and air bubble sheets, suitable for various packaging material cutting scenarios.

- User-friendly operation: Features simple control interfaces and easy material feeding, reducing the learning curve for operators.

- Stable performance: Built with high-quality components, ensuring stable and reliable operation during long-term use.

Technical Parameters

| Model | ZT120-CM |

| Max width | 1200mm |

| Speed | 15M/min |

| Tolerance | 1mm |

| weight | 300kg |

| power | 5kw |