Description

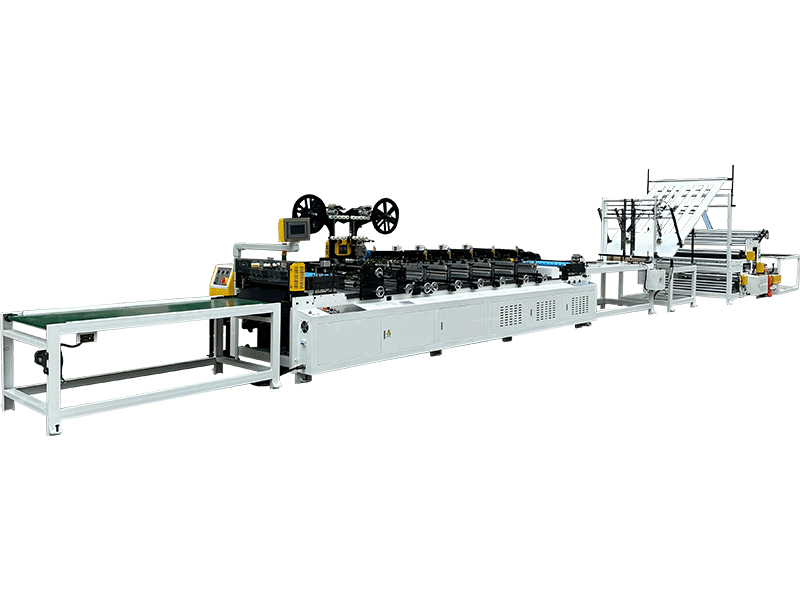

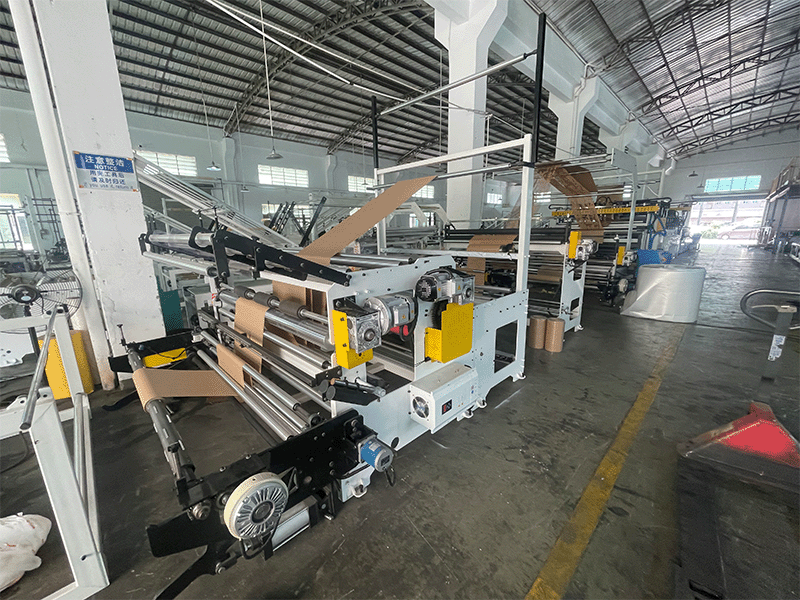

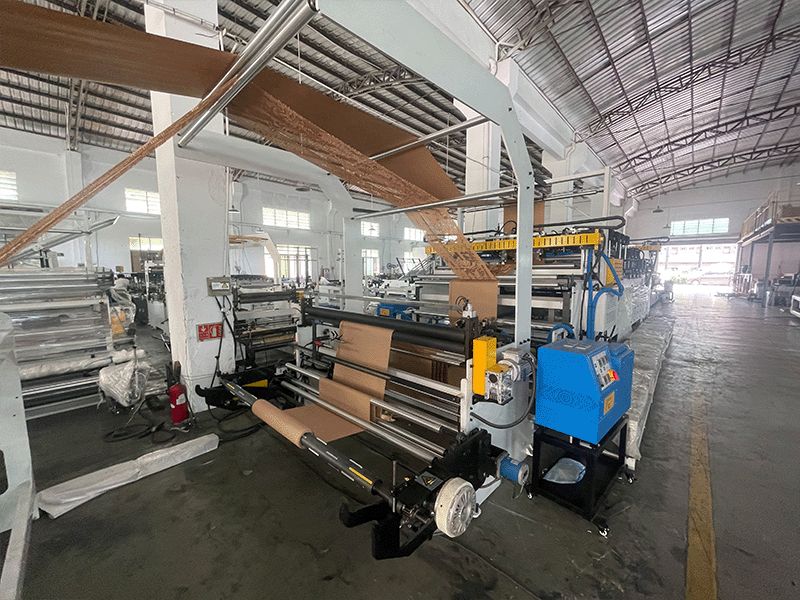

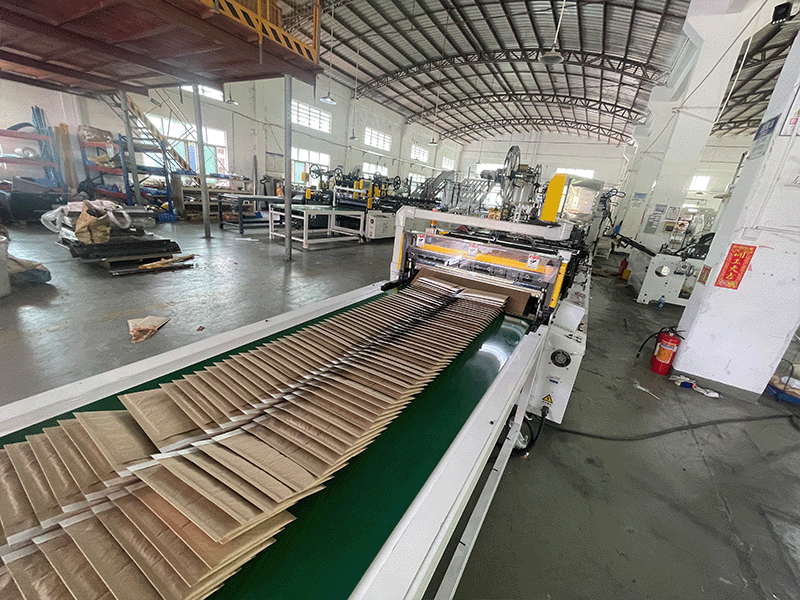

As a professional eco-friendly envelope-making equipment, it follows a streamlined "honeycomb paper unwinding → folding forming → edge sealing → cutting" workflow. It uses honeycomb paper (a porous, buffer-rich material) as the core raw material: first, the unwinding unit feeds the honeycomb paper stably, with tension control to avoid paper deformation; then, the folding unit shapes the flat honeycomb paper into an envelope structure (with a flap for sealing); next, the sealing unit uses pressure bonding (no harmful adhesives, aligning with eco-friendly needs) to seal the envelope edges; finally, the cutting unit trims the continuous material into individual honeycomb paper envelopes of set sizes (e.g., small for documents, medium for small gifts).

The machine is optimized for honeycomb paper’s texture—its porous structure ensures the finished envelopes have good cushioning (protecting inner items from light impact) while remaining lightweight. The entire production process is pollution-free, matching the demand for green packaging solutions.

Feature

- Eco-friendly core advantage: Uses recyclable, biodegradable honeycomb paper as raw material—replaces plastic envelopes, reducing environmental pollution.

- Buffer performance: Honeycomb paper’s porous structure gives envelopes natural cushioning, protecting small, fragile items (e.g., jewelry, small electronics) from light collisions.

- Integrated efficient production: Combines unwinding, folding, sealing, and cutting into one line—simplifies workflow, with a production speed of 30-60 envelopes per minute.

- Flexible size customization: Supports adjusting envelope length, width, and flap size via the control panel—adapting to document envelopes, small gift envelopes, and e-commerce small-package envelopes.

- Adhesive-free sealing option: Offers pressure bonding sealing (no toxic adhesives) to enhance eco-friendliness; also compatible with water-based biodegradable adhesives for stronger seals.

- Stable operation: Equipped with microcomputer control and automatic paper deviation correction—ensures consistent envelope size and neat edges, avoiding material waste.

Technical Parameters

| product name | Honeycomb Paper Bag Making Machine |

| Suitable material | Kraft paper 100-130g/sm² |

| Machine speed | 20-60pcs/min |

| Maximum bag size | one line 550mm×450mm、two lines 250mm×450mm |

| Effective width of unwind | Kraft paper 1150mm honeycomb paper 520mm |

| Effective diameter of unwind | kraft paper φ1300mm honeycomb paperφ400mm |

| Voltage: | three pahse AC380V 50HZ 50Kw |

| Air pressure | over 6kg constant pressure |

| Overall Dimension(LXWXH) | 23m×2.3m×2.3m |

| Machine weight | 9tons |