Description

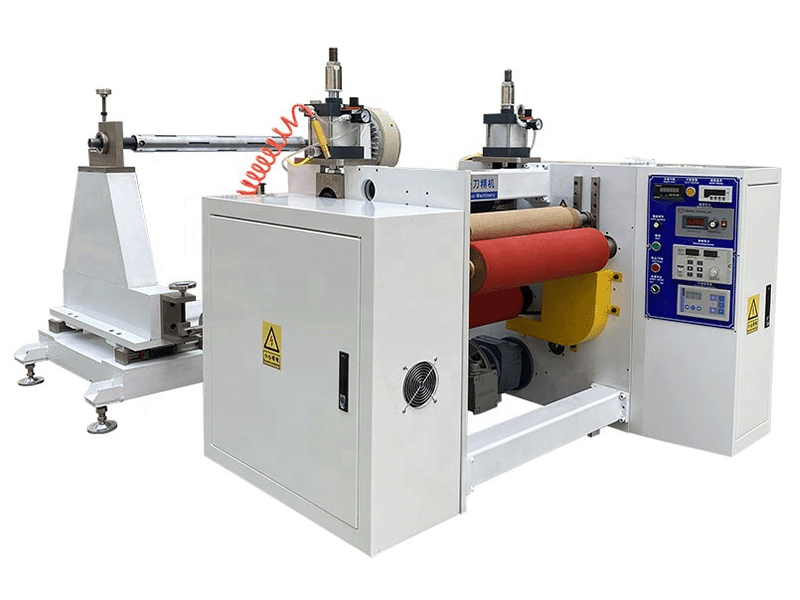

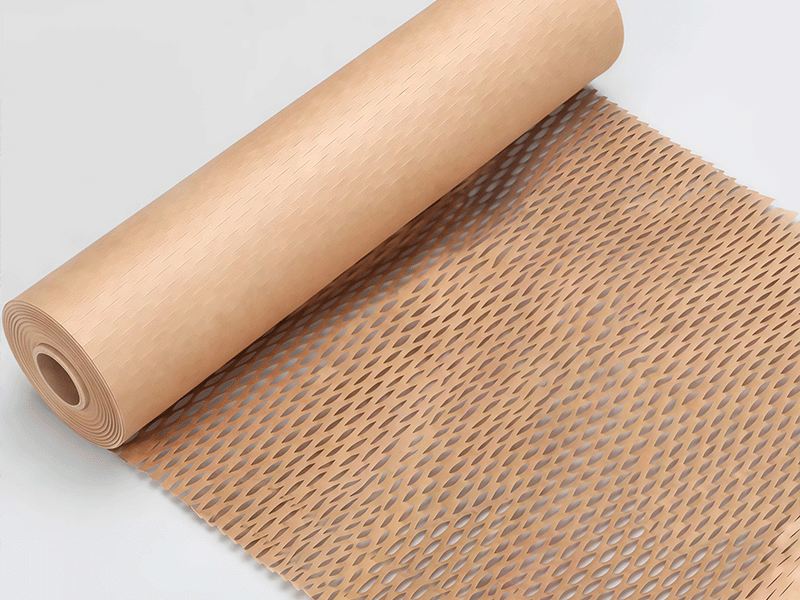

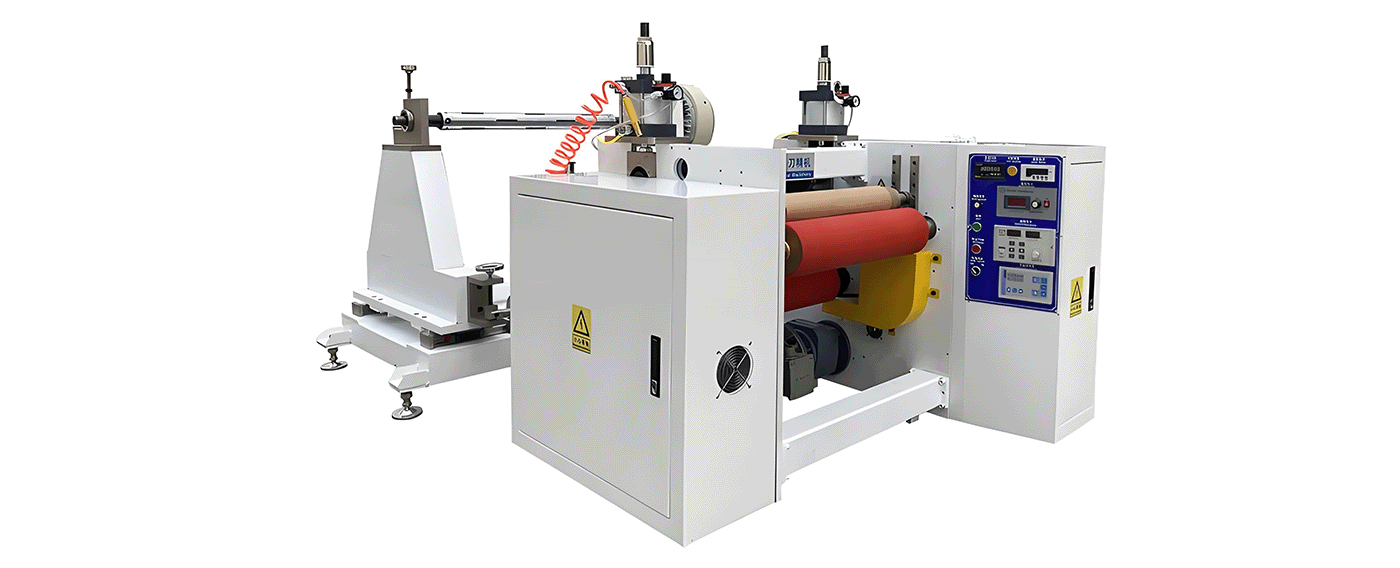

As a professional equipment for honeycomb paper production, this machine integrates unwinding, rolling forming, cutting, and rewinding into one continuous process—no need for separate steps, greatly improving production efficiency. Its core working principle is to first unroll the base paper (70g-100g, such as kraft paper, shock-absorbing paper) via the unwinding unit. The ultrasonic automatic web guide controller in this unit adjusts the paper position in real time to avoid deviation, ensuring the base paper enters the forming unit smoothly.

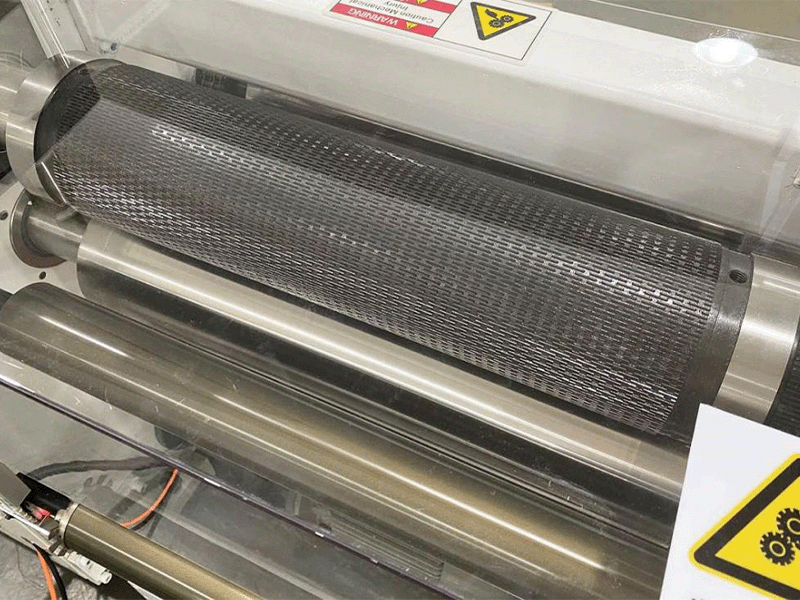

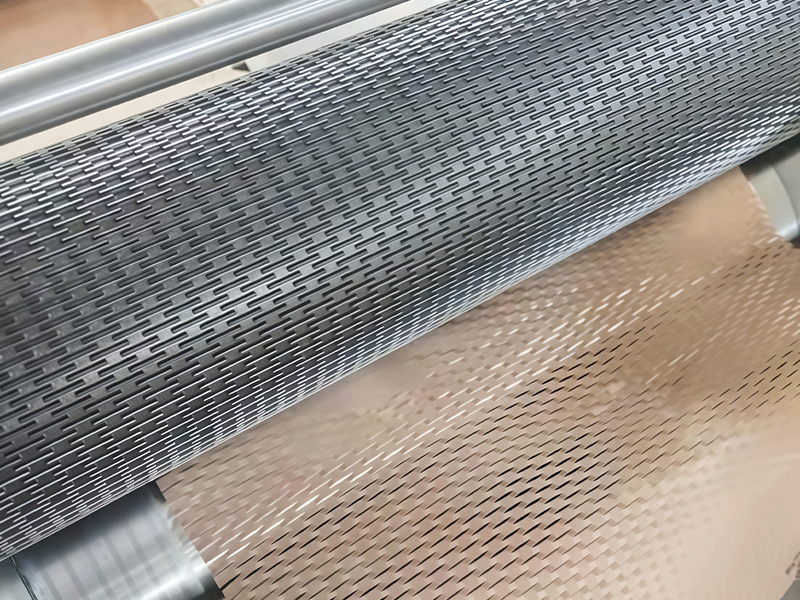

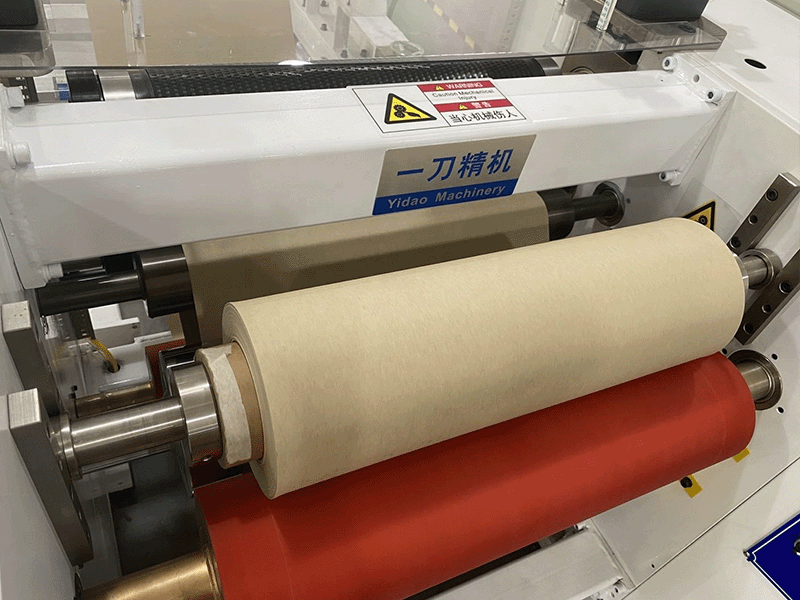

In the roller forming unit, multiple sets of pressure-adjustable die cutters and rollers work together to press the flat base paper into a honeycomb grid structure. The pneumatic cylinder controls the die cutters to move up and down, and the pressure can be flexibly adjusted according to the paper weight (70g-100g), ensuring the formed honeycomb structure is uniform and tough. During the entire process, the magnetic powder brake and clutch control the paper tension, preventing stretching, deformation, or wrinkles.

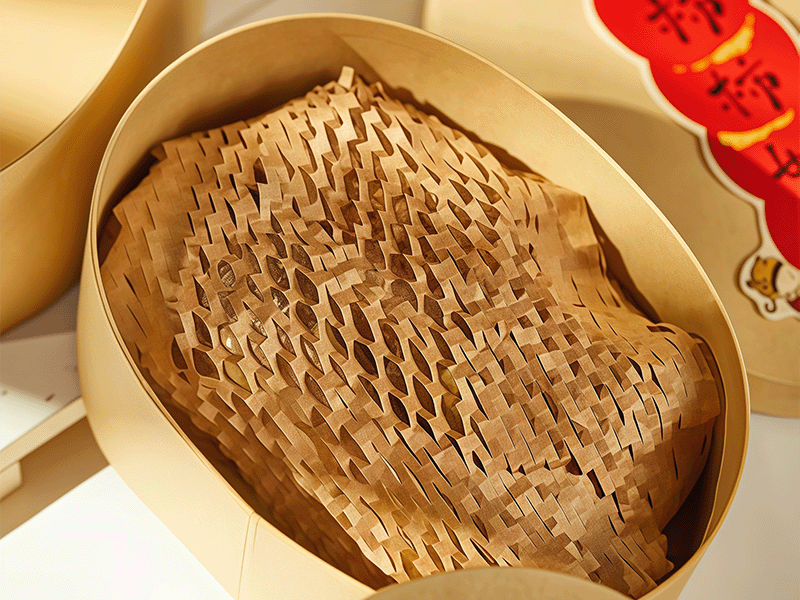

After forming, the machine can either rewind the honeycomb paper into rolls or cut it into sheets (roll-to-sheet cutting is optional). The automatic meter counting device stops the machine once the set length is reached, ensuring consistent size of finished products. The main motor is equipped with an inverter for speed regulation, adapting to different production rhythms and meeting diverse output needs.

Features

- Integrated workflow: Combines unwinding, cutting, forming, and rewinding in one process, simplifying production steps and improving efficiency.

- Versatile base paper compatibility: Suitable for die-cutting honeycomb paper, wrapping paper, shock-absorbing kraft paper, and fish net paper with weights from 70g to 100g.

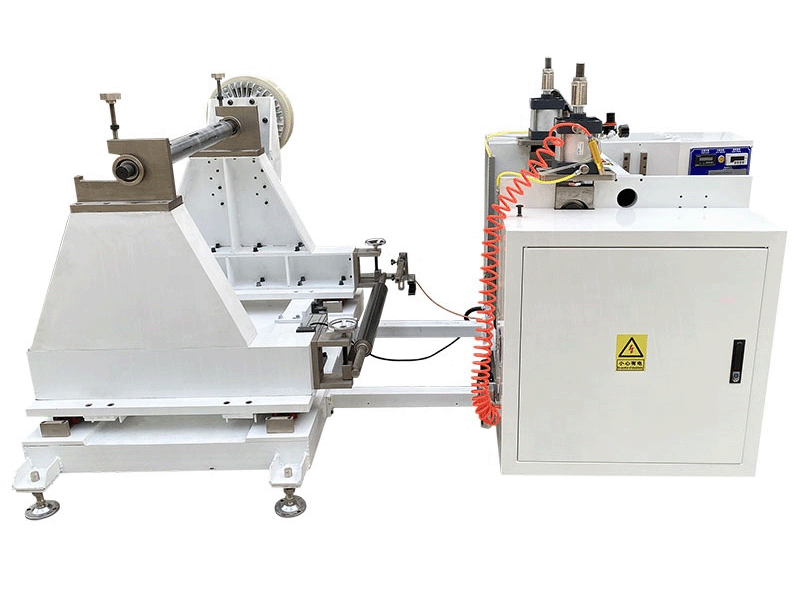

- Automatic unwinding with deviation correction: Equipped with an air-inflated unwinding shaft (can carry base paper rolls up to 1200mm in diameter, 1 ton in weight) and ultrasonic automatic web guide controller—real-time fine-tuning of feed position (left-right stroke up to 100mm) to avoid paper drift.

- Precise roller forming: Core unit with pressure-adjustable die cutters and rollers; pneumatic cylinder controls die movement, ensuring uniform honeycomb structure for different paper weights.

- Stable tension control: Uses magnetic powder brake and clutch to adjust tension during conveying, forming, and winding—preventing paper stretching, deformation, or wrinkles.

- Flexible speed & length control: Main motor with inverter for speed regulation; automatic meter counting device stops automatically at the set length, ensuring consistent finished product size.

- Optional roll-to-sheet cutting: Supports both roll rewinding and sheet cutting, adapting to diverse application scenarios (e.g., rolls for large-scale packaging, sheets for small-batch goods).

Technical Parameters

| Web working width | 600mm |

| Mould effective width | 500mm |

| Unwinding diameter | 0-1200mm |

| Unwinding stand weight | 1Ton ( can make more bigger ) |

| Unwinding shaft | 3 inch inflatable air shaft |

| Rewinding shaft | 1 inch/1.5 inch/2 inch/ 3 inch |

| Machine size | 2620*1640*1160(LWH) |

| Machine weigth | 1000Kgs |

| Power supply | 380V 3 Phases 5 Wires |

| Air pressure | 6-8Kg/c Square meter |