Description

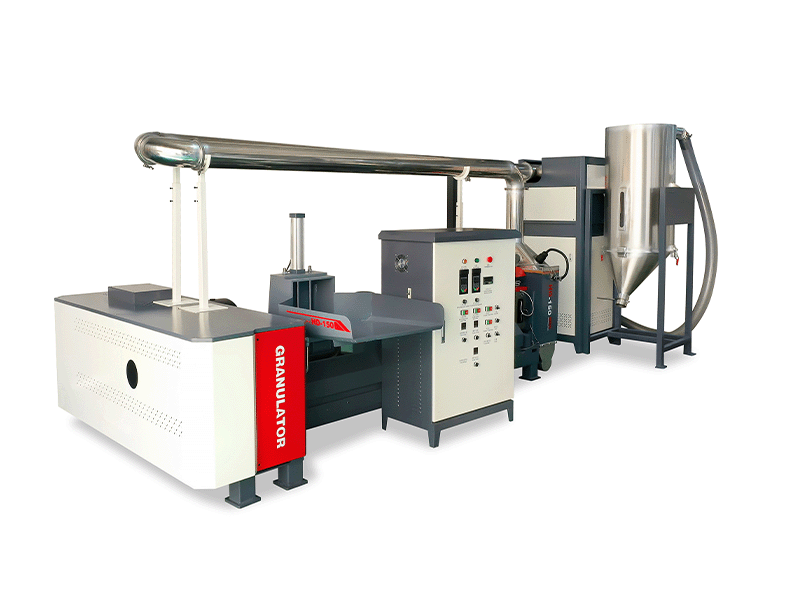

As a miniaturized PE film and bubble film recycling solution, this New PE Film Recycling Unit abandons the complex water cooling and heating structures of traditional granulators, adopting an innovative "mechanical friction granulation" process. The workflow is simple and efficient: first, waste materials (such as used PE packaging film, discarded bubble film, or bubble wrap scraps) are directly fed into the machine’s feeding port—no pre-cleaning or drying is required for clean, low-impurity films.

Inside the machine, a set of high-hardness alloy knife sets rotate at high speed, generating friction between the knives and the plastic film. This friction not only cuts the film into small fragments but also relies on the mechanical force of friction to shape the fragments into uniform granules—entirely avoiding the need for heating to melt plastic or water to cool granules. Compared with traditional water-ring or hot-cut granulators, this unit reduces equipment complexity by over 50%: it has no water pipes, heating coils, or cooling tanks, so the overall size is significantly smaller—fitting into narrow spaces that traditional granulators cannot.

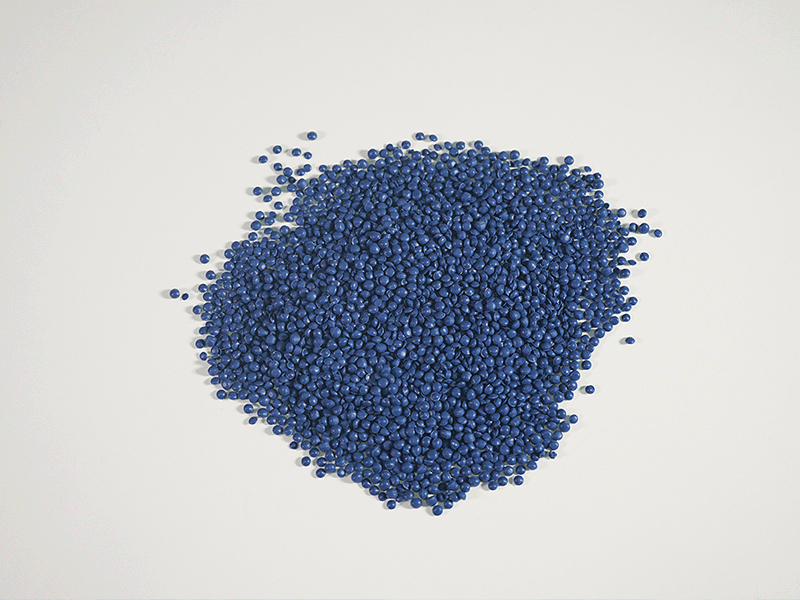

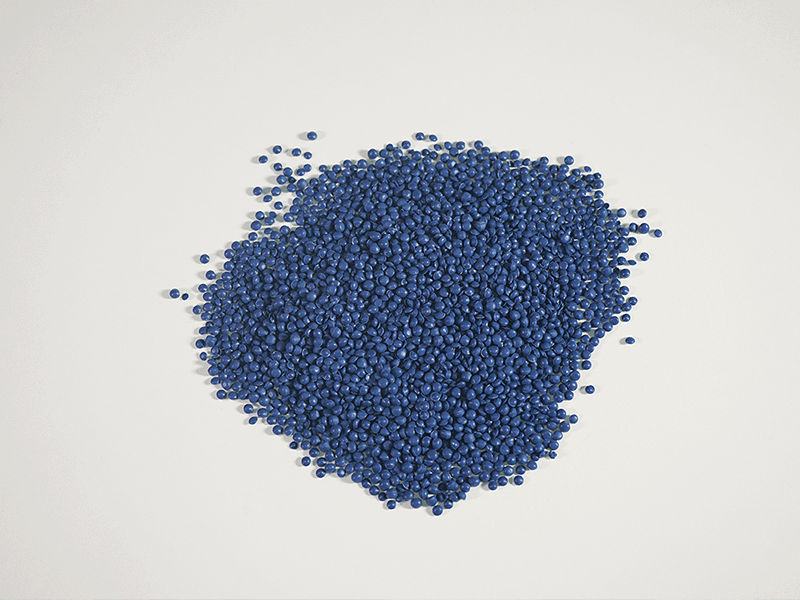

The unit is optimized for the characteristics of thin, flexible films like bubble film and PE film: the knife set gap is adjustable to prevent film winding, ensuring smooth cutting and granulation. The produced recycled granules have consistent particle size, and since no heating is involved, the original material properties of the plastic are better preserved—suitable for reprocessing into low-demand plastic products such as small PE film bags or bubble film cushioning fillers.

Features

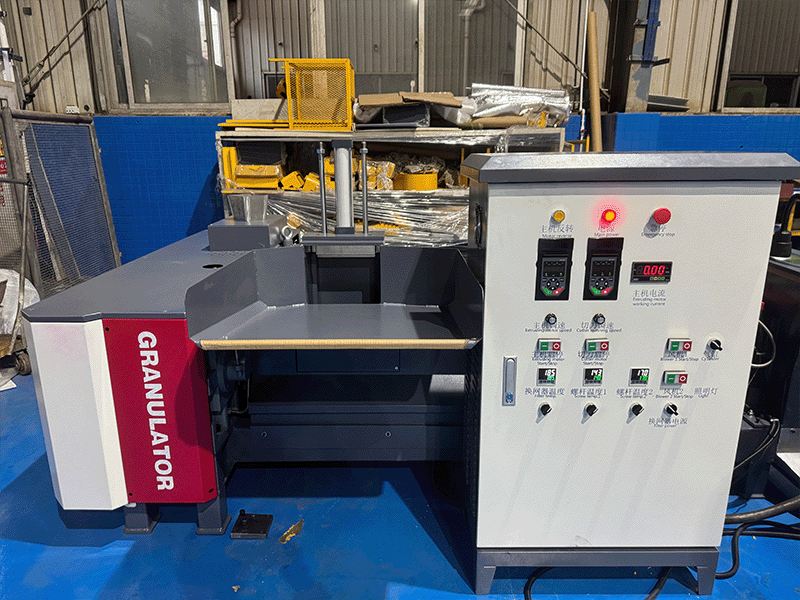

- No-water, no-heating operation: Relies on inter-knife friction for cutting and granulation, eliminating water consumption and heating energy costs—reducing operation and maintenance expenses.

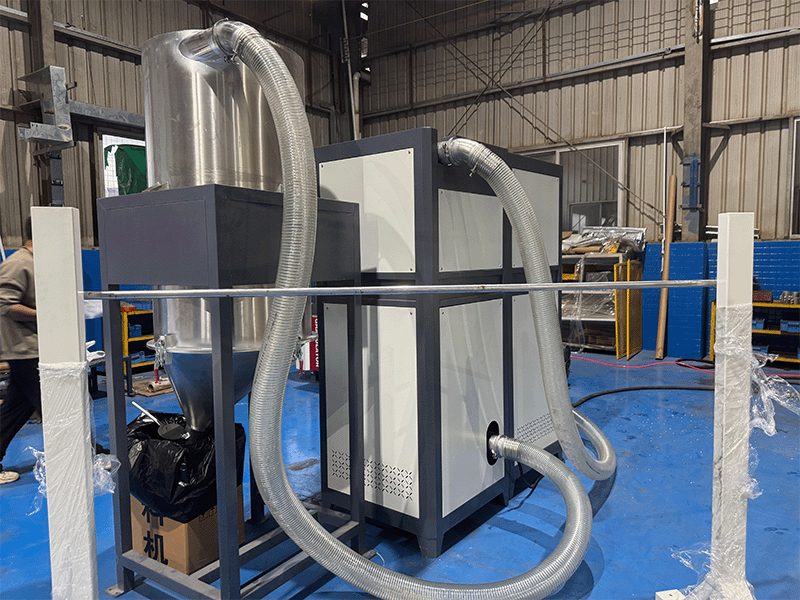

- Compact size: Footprint is much smaller than traditional granulators, saving workshop space and adapting to small-scale production environments (e.g., small workshops, retail packaging stores).

- Wide material adaptability: Specializes in recycling PE film, bubble film, and bubble wrap; can also process clean PP film scraps—meeting diverse small-volume flexible film recycling needs.

- Simple workflow: No pre-heating, water preparation, or post-dehydration steps; waste film is fed directly for granulation—lowering operation difficulty and saving labor.

- Low energy consumption: Without heating elements or water pumps, the power demand is only 1/3 of traditional small granulators, achieving energy-saving operation.

- Particle quality stability: High-hardness alloy knife sets ensure uniform granule size; no heating avoids material degradation, preserving the usability of recycled granules.

Technical Parameters

| Parameter | Specification |

| Model | ZT90-RL |

| Output | 70-90 Kg/h |

| Avg. Power Consumption | 200-250 Kwh/ton |

| Total Power | 25 Kw |

| Machine Size | 3.9 m² |

| Machine Weight | 1260 Kg |

| Extruding Motor | 18.5 Kw |

| Reducer | 173 |

| Screw Dia. | 90 mm |

| Inverter | 18.5 Kw |

| Cutting Motor | 0.75 Kw |

| Blower | 1.5 Kw |

| Storage tank | 1 |