Description

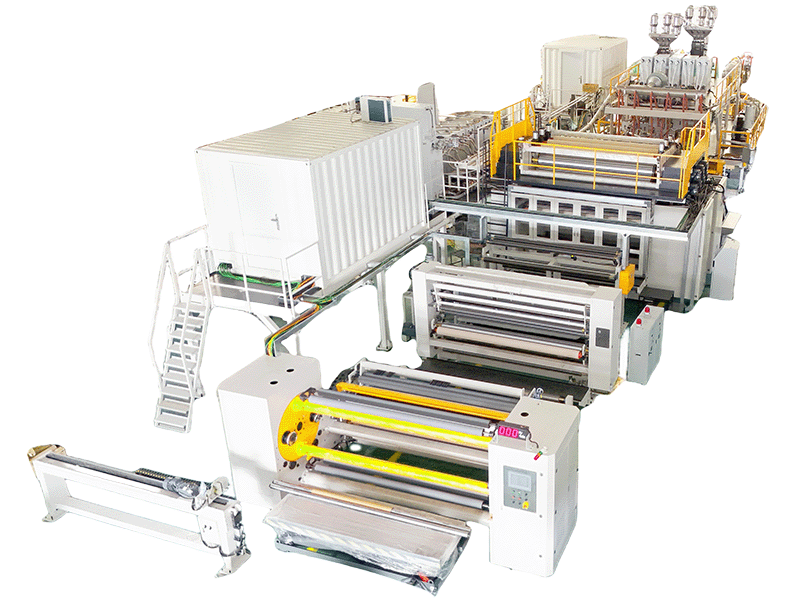

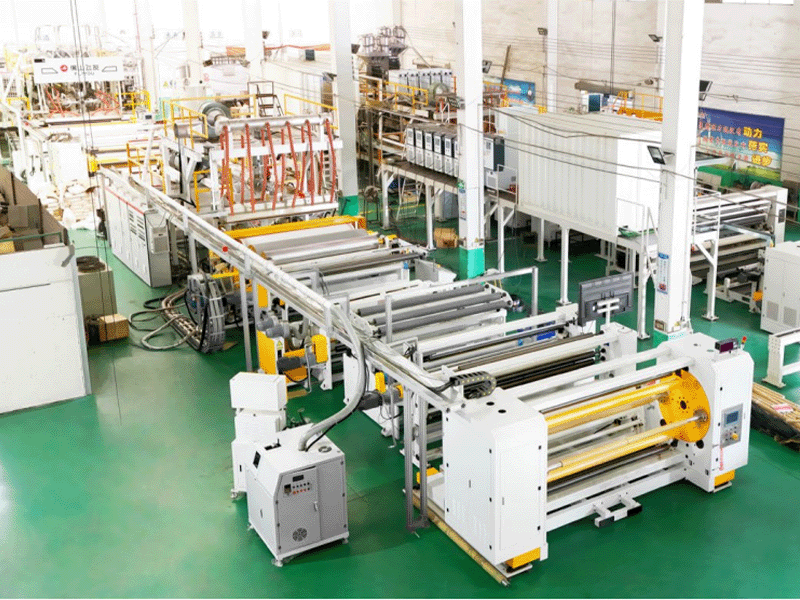

The PE Cast Film Extrusion Line adopts a multi-stage production process to ensure the production of premium PE cast films. It starts with a high-performance extruder that fully melts and plasticizes PE raw materials. The molten material is then precisely cast onto a chilled casting roller via a die head, where rapid cooling and solidification occur to form a uniform film.

Subsequent processes include thickness measurement, edge trimming, and winding. The line is equipped with intelligent control systems to monitor and adjust key parameters such as temperature, speed, and tension in real-time, ensuring consistent film quality. Optional configurations like online coating or embossing units can be added to meet specific functional requirements of the films.

Feature

- Efficient Extrusion System: Utilizes a high-torque extruder with optimized screw design for efficient melting and mixing of PE materials, ensuring stable output and uniform material properties.

- Precise Casting Process: The casting unit with precision temperature-controlled casting rollers enables rapid and uniform cooling of the molten film, resulting in excellent flatness and optical properties.

- Intelligent Control: Equipped with a PLC-based control system and touchscreen HMI, allowing real-time monitoring and adjustment of production parameters for precise control over film thickness, width, and other attributes.

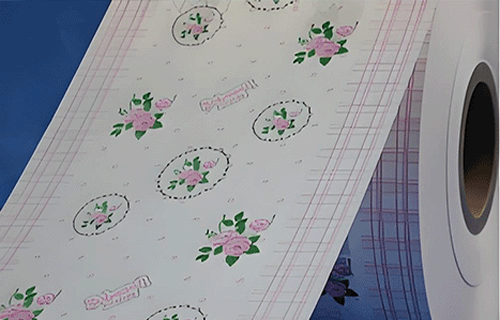

- Versatile Customization: Supports production of films with a wide range of widths and thicknesses. Can be customized to produce films with special properties such as high transparency, high tensile strength, or specific surface textures.

- High Production Efficiency: The line operates at high speeds while maintaining stable production, significantly increasing output and meeting large-scale production demands.

- Reliable Components: Incorporates high-quality components and bearings, ensuring stable operation, low failure rates, and long service life of the equipment.

Technical Parameters

| Film width range | 1000-3800mm |

| Machine design speed | 250m/min |

| Product gsm | 11-40g |

| Applicable materials | Breathable particles, PE particles |

| Production speed | 30-230m/min |

| Installed capacity | 850KW |

| Machine wall panel | CNC machining |