Description

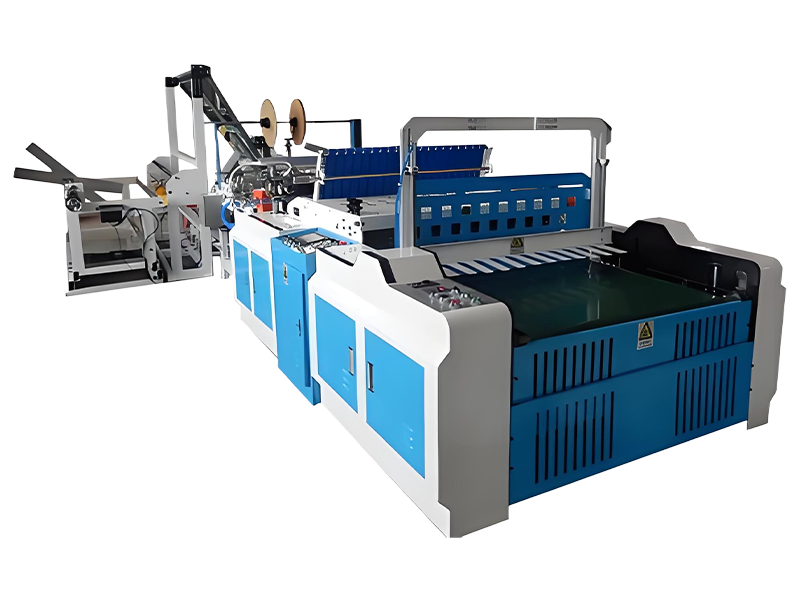

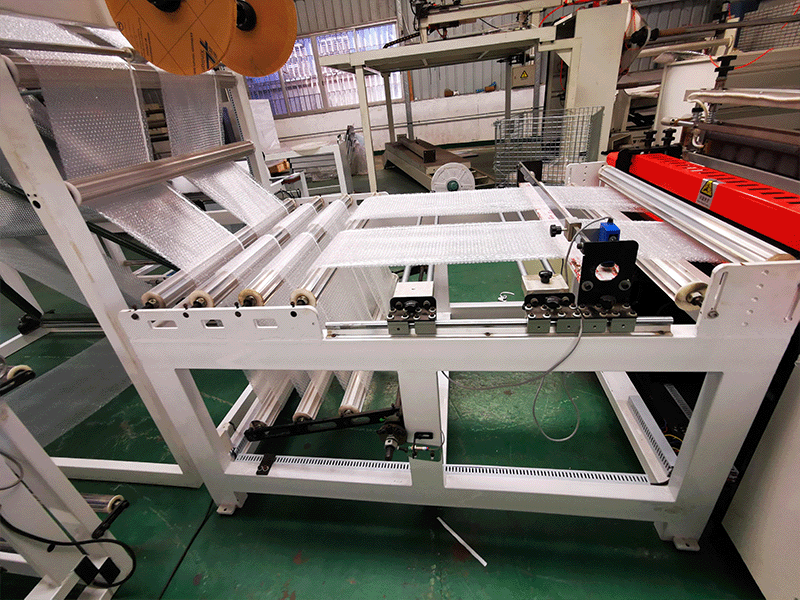

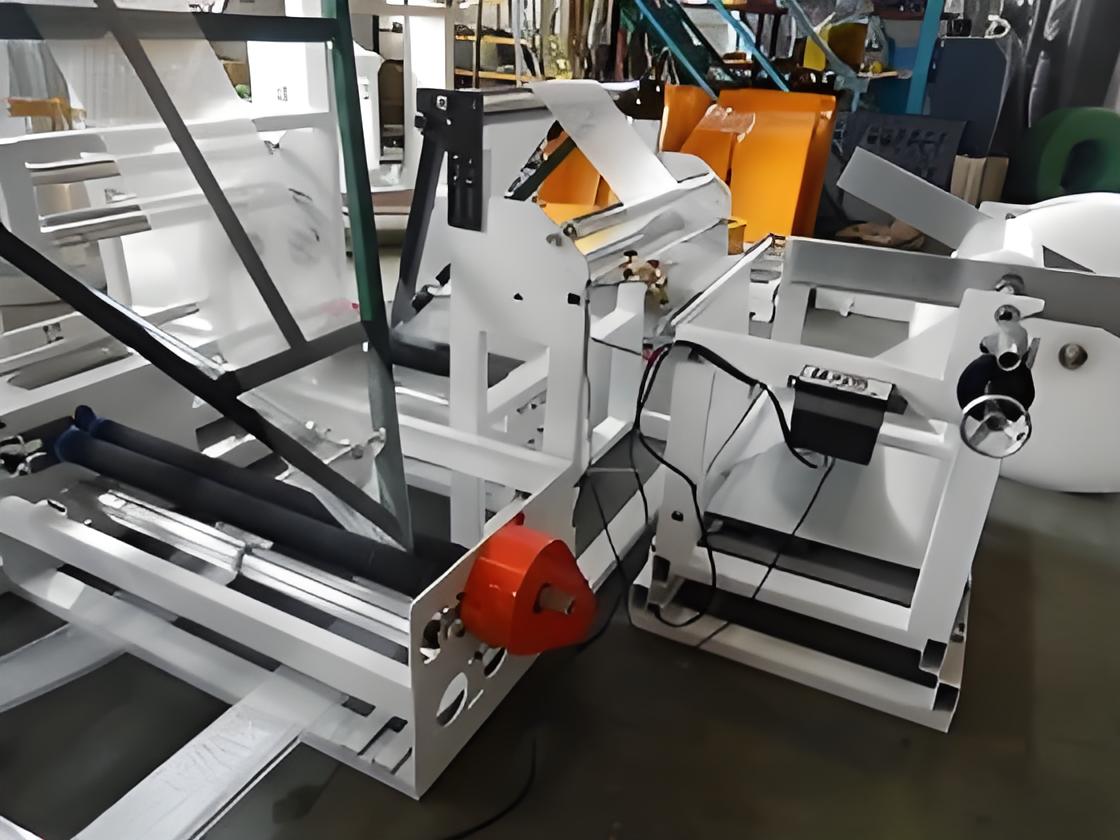

As a professional air bubble pouch machine, it follows a streamlined "unwinding → double-sealing → cutting → collection" workflow. EPE foam or bubble film (raw material for air bubble bags) is fed stably via the unwinding unit, then pressed into double-sealed air bubble bags by high-temp sealing heads for tight, protective seals.

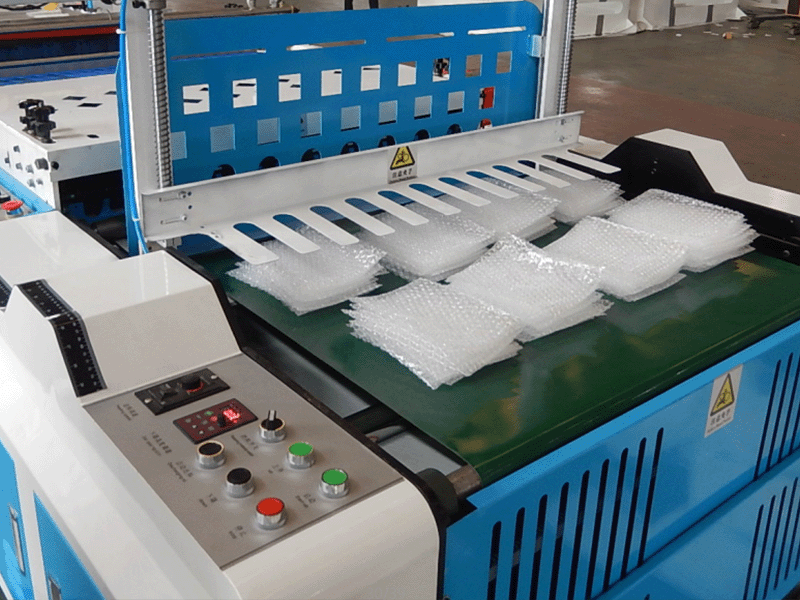

With "two-out" parallel sealing and cutting components, this air bubble pouch machine produces 2 air bubble bags per cycle (max 100/min). After cutting to set sizes, finished air bubble bags are auto-conveyed to the storage table for orderly stacking. A simple control panel lets users adjust air bubble bag length, width, and sealing temperature easily.

Features

- Double-seal air bubble bag production: Specializes in making double-sealed air bubble bags and EPE foam bags, ensuring strong sealing that enhances cushioning and moisture resistance for packaged items.

- "Two-out" high efficiency for air bubble pouches: Supports simultaneous production of 2 air bubble bags/pouches, with a maximum speed of 100 bags per minute—far outperforming single-out air bubble pouch machines.

- Dedicated storage for air bubble bags: Equipped with a storage table that collects and arranges finished air bubble bags neatly, reducing manual sorting work and boosting post-production efficiency.

- Versatile for air bubble/bubble film materials: Adapts to different thicknesses of EPE foam and bubble film (core materials for air bubble bags), meeting diverse air bubble pouch packaging needs.

- Adjustable air bubble bag parameters: Allows flexible setting of air bubble bag length, width, and sealing temperature via the panel—suitable for small electronics air bubble pouches to large furniture air bubble bags.

- Stable air bubble pouch production: Adopts tension control in unwinding and precise temperature control in sealing, ensuring consistent air bubble bag quality (uniform seals, no burrs) during long runs.

Technical Parameters

| Model | ZT100-BM |

| Raw materials | Air Bubble Film/EPE Foam |

| Maximum width | 70-900 |

| Maximum length | 70-1000 |

| Production Capacity | 30-120 per minute |

| Total Power | 5.5 |

| Total Weight | 1200 |

| Power Supply | 220V,50Hz,singlephase |