Description

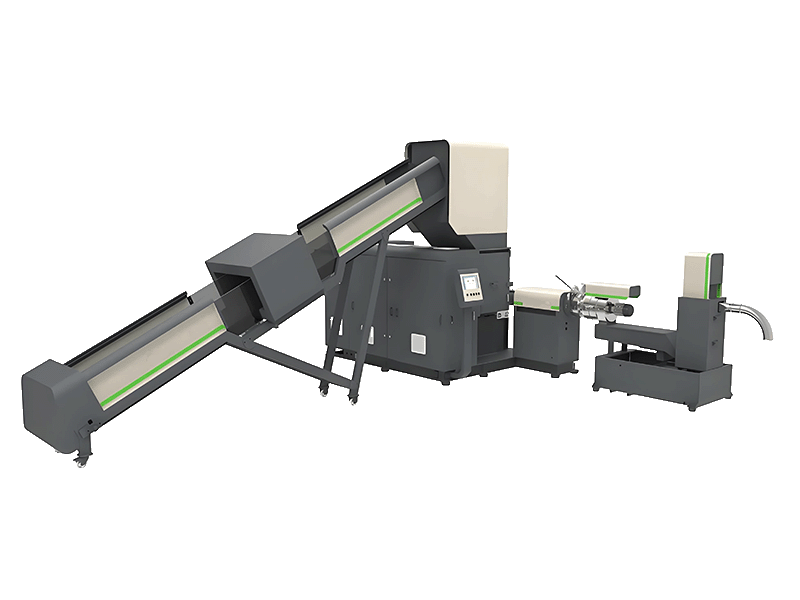

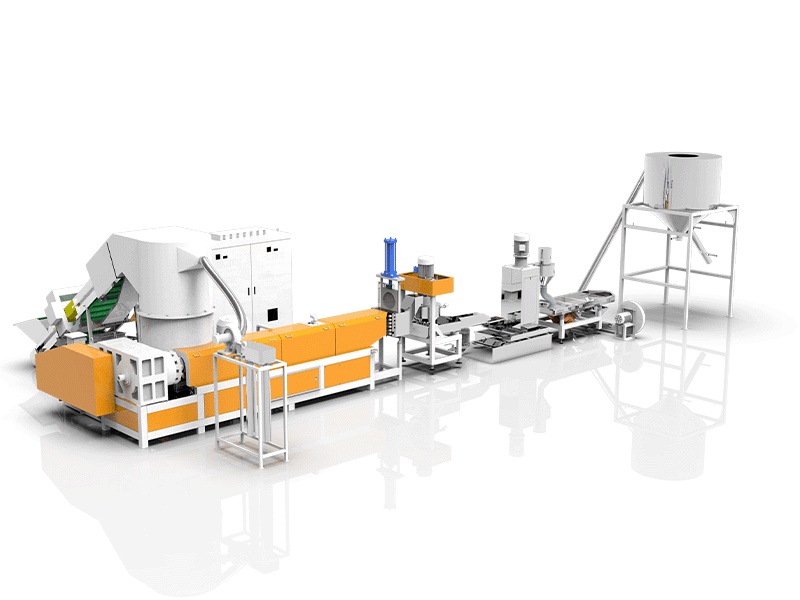

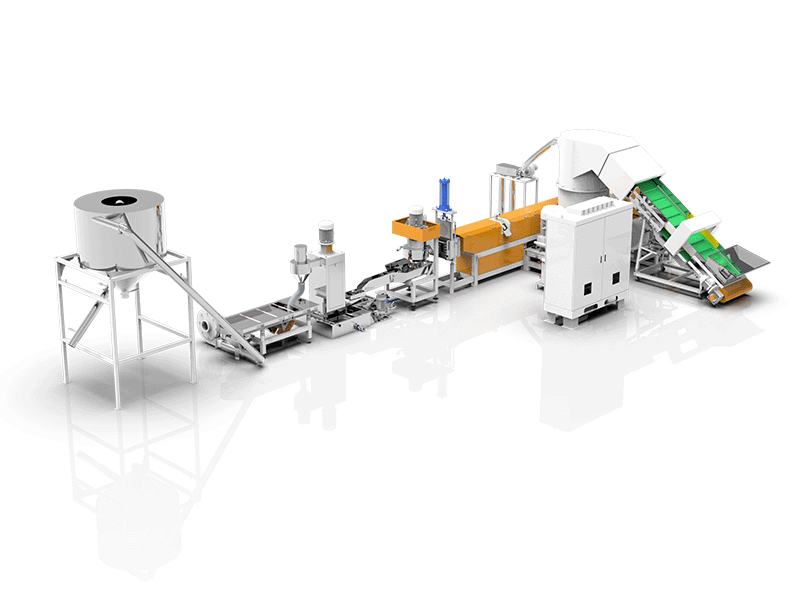

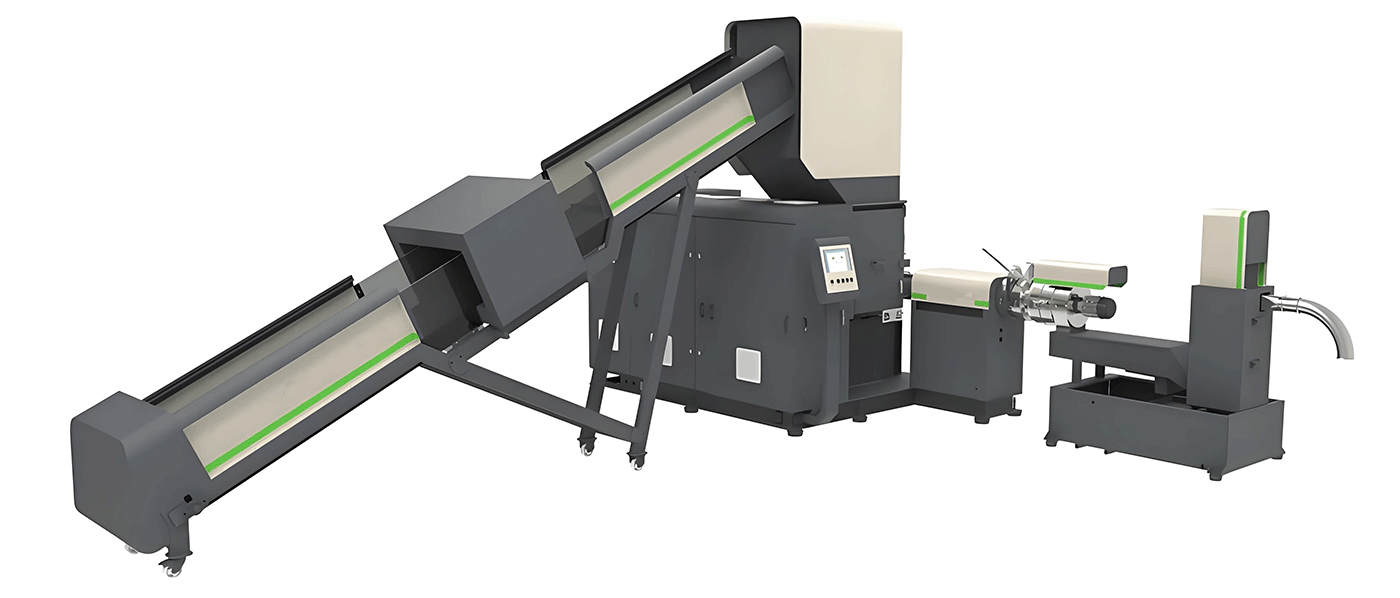

As a multi-functional Water Ring Plastic Recycling Machine, it integrates crushing, melting, extrusion, cooling and granulating into one continuous workflow—with core adaptability to bubble film and bubble wrap recycling, hence also recognized as a high-efficiency bubble film recycle machine and bubble wrap recycle machine. The processing starts with feeding waste plastic films (such as used PE bubble film, PP bubble wrap, HDPE packaging films or ABS plastic scraps) into the crushing unit, where they are shredded into uniform small pieces. These crushed materials are then conveyed to the extruder, where they are fully melted and plasticized under precise temperature control to form a homogeneous molten plastic melt.

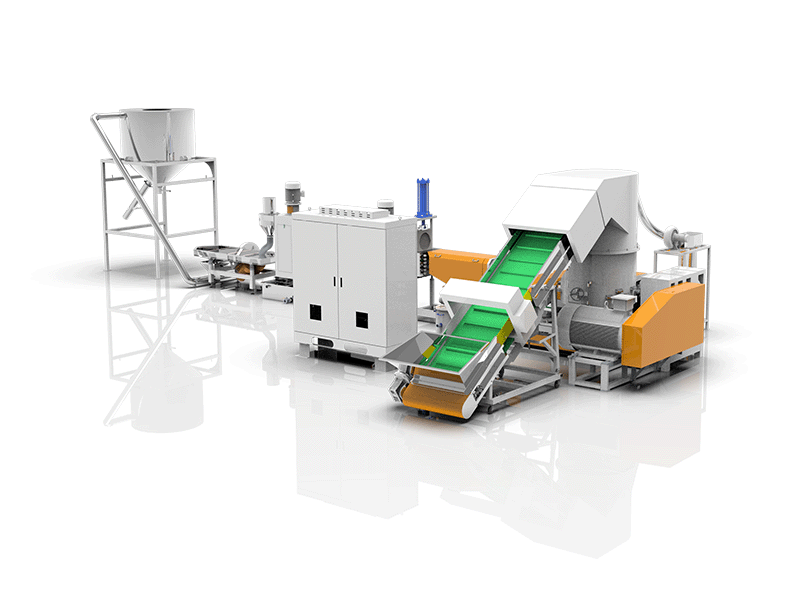

The key advantage of this machine lies in its water ring cooling system: the molten plastic is extruded through a die head into strands, which are immediately cooled by a circular water curtain in the water ring unit. Compared with traditional air cooling, the water ring design achieves faster, more uniform cooling—effectively preventing granule deformation and ensuring consistent particle size and smooth surface of recycled granules. After cooling, the plastic strands are cut into regular granules by the high-speed cutter, and then undergo dehydration and drying to obtain finished recycled plastic granules.

Notably, as a dedicated bubble film recycle machine and bubble wrap recycle machine, it is optimized for the characteristics of thin, flexible bubble film/bubble wrap materials—with a specially designed crushing chamber that avoids material winding and ensures efficient shredding, while the extruder’s screw structure is adjusted to adapt to the low-density nature of bubble film, ensuring full plasticization without residue.

Features

- Multi-name versatility: Functions as Water Ring Plastic Recycling Machine, bubble film recycle machine and bubble wrap recycle machine—covering multiple search needs and adapting to diverse plastic film recycling scenarios.

- Wide material compatibility: Specializes in recycling PE, PP, HDPE, ABS and other plastic films, with a focus on bubble film and bubble wrap recycling, meeting the needs of multi-material waste plastic processing.

- Advanced water ring cooling: Adopts water ring cooling system, which provides better cooling effect than traditional air cooling—ensuring recycled granules have uniform size, smooth surface and high density, improving product quality.

- Optimized for bubble film/wrap: As a professional bubble film recycle machine and bubble wrap recycle machine, it is equipped with a anti-winding crushing chamber and a bubble film-adapted extruder screw—solving the problem of difficult processing of thin, flexible bubble materials.

- High recycling efficiency: Integrates crushing, extrusion, cooling and granulating into one line, with continuous production capability—greatly reducing manual intervention and improving the efficiency of plastic film recycling.

- Environmental protection and energy saving: The water ring cooling water can be recycled after treatment, reducing water waste; the extruder adopts energy-saving heating technology, lowering power consumption while realizing resource reuse of waste plastics.

Technical Parameters

| Model | ZT110-RL Water wing Plastic Recycling Machine |

| Screw diameter | 110mm |

| Capacity | 150-250kg/h |

| Weight | 5500KG |