Ztech offers a comprehensive range of advanced machinery to meet the evolving needs of the packaging industry. Our key product include:

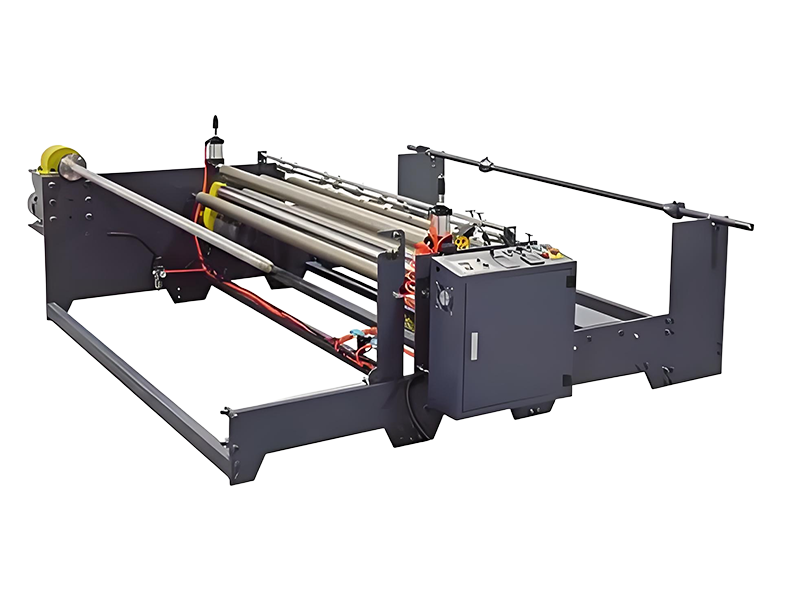

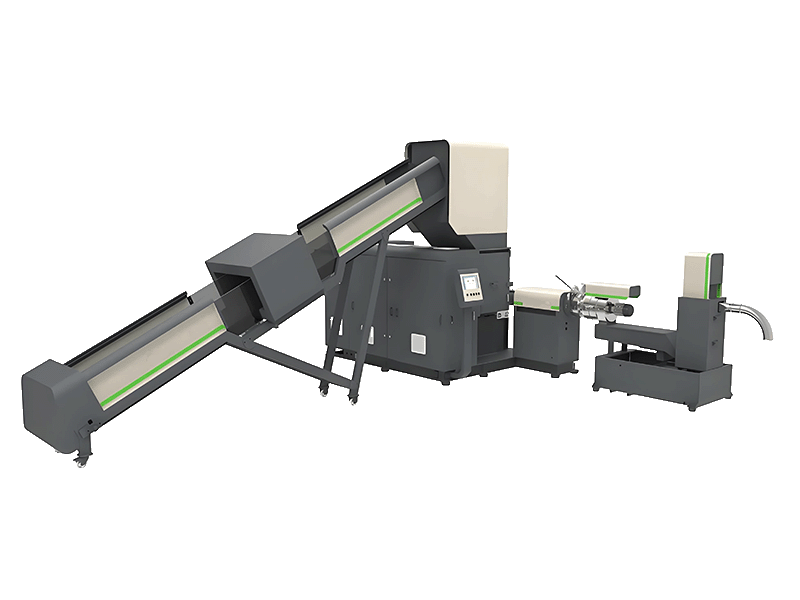

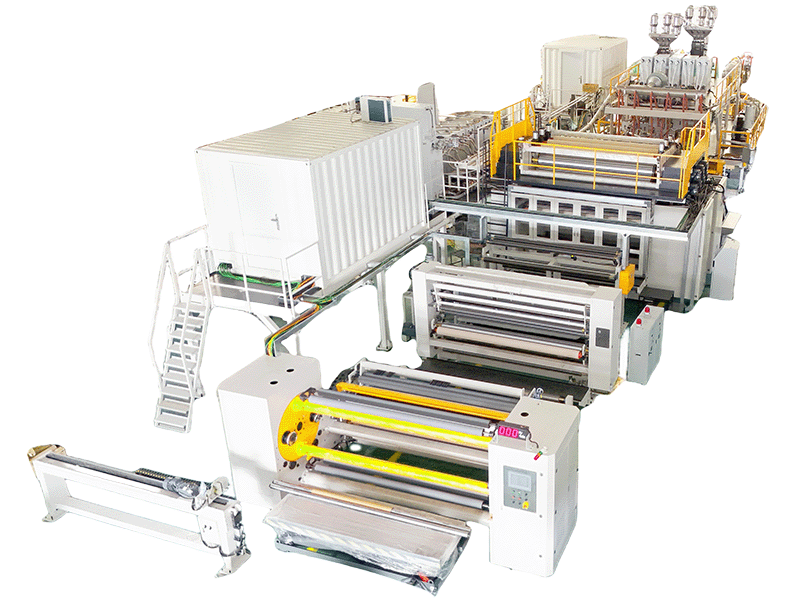

Air Bubble Film Machine

Precision machines for producing multi-layer air bubble films, including 2-layer, 3-layer, 5-layer, and 7-layer extrusion lines. Our ABA coextrusion and nylon coextrusion machines are ideal for eco-friendly and high-performance applications.

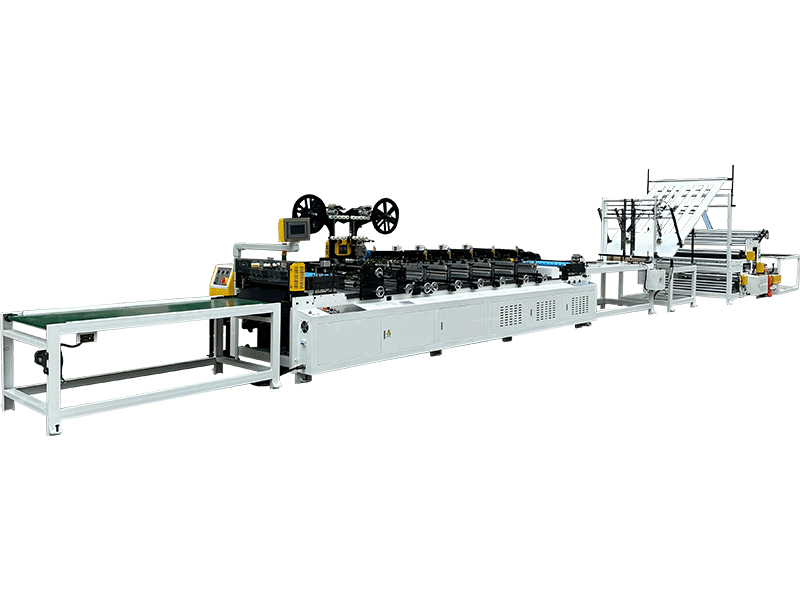

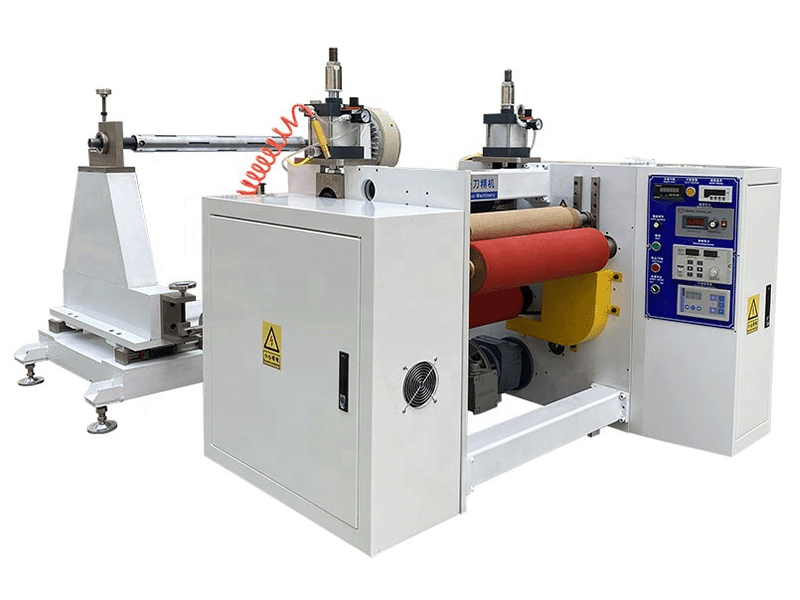

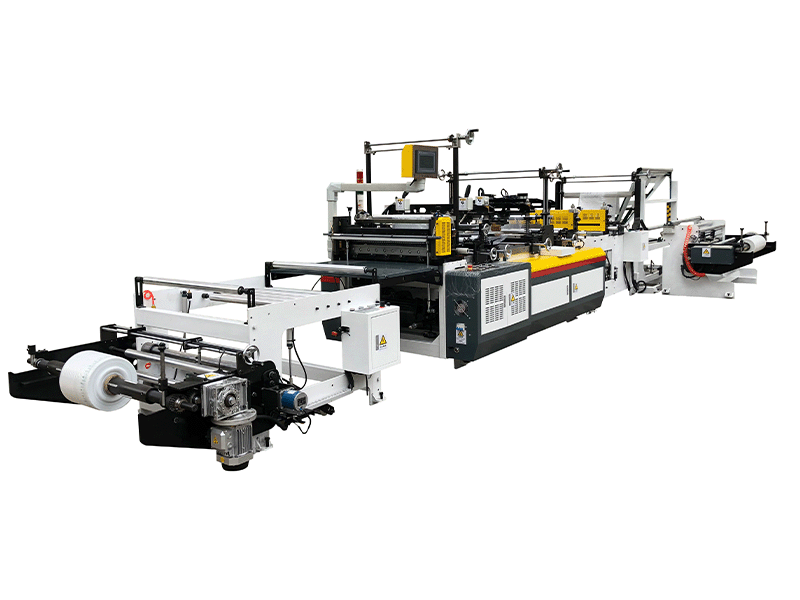

Bubble Bag Making Machine

Machines for producing air bubble bags, EPE foam bags, and courier bags, including two-seal side and three-seal side options. We also offer machines for air bubble mailers and buffer air column bags.

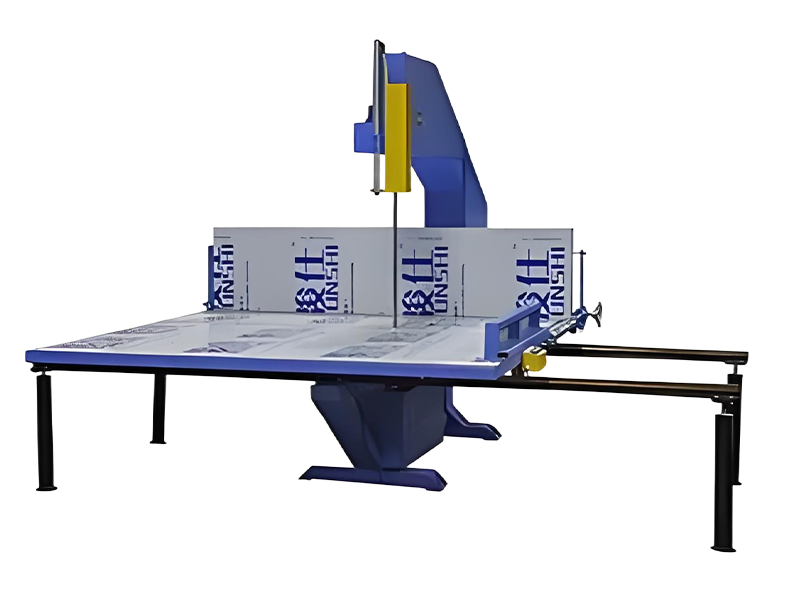

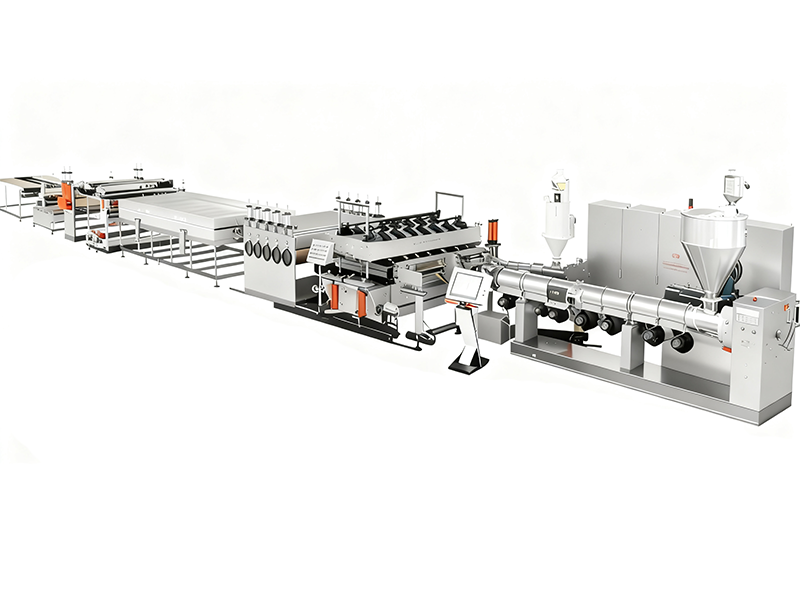

PP Sheet & Board Machine

High-quality machines for manufacturing PP bubble sheets, hollow boards, and honeycomb sheets, suitable for packaging and construction industries.

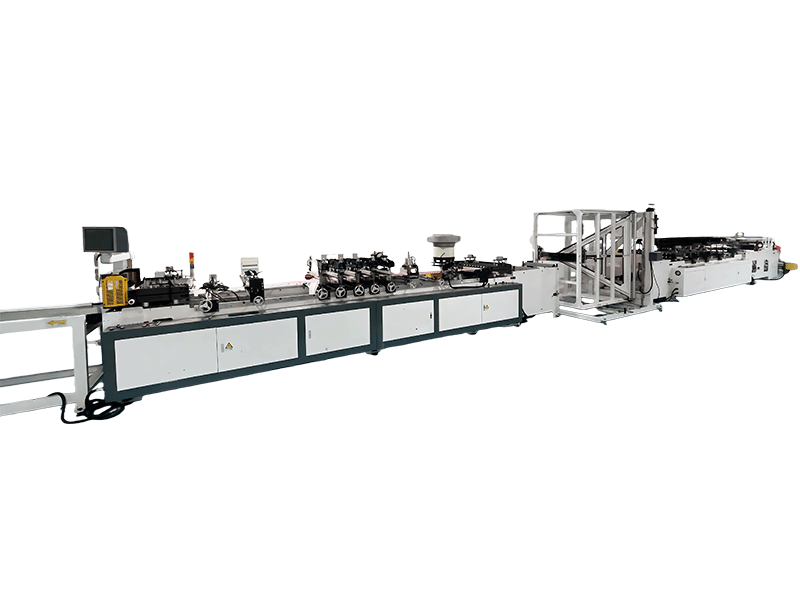

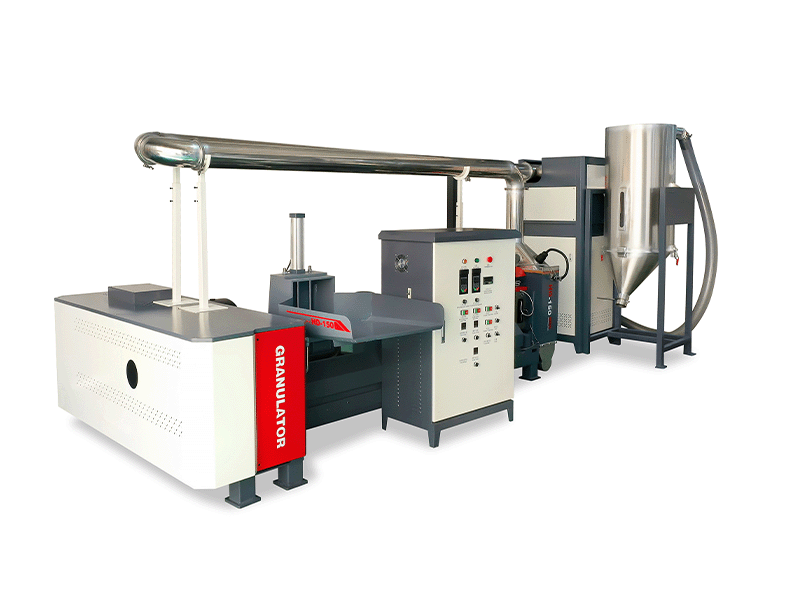

Plastic Recycling Machine

PE film recycling and water ring plastic recycling systems for sustainable operations, converting waste into reusable materials.